MC nylon MC901 round bar

-

$3.901-99 Kilogram

-

$3.80100-999 Kilogram

-

$3.70≥1000 Kilogram

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | Enough |

|---|---|

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Guangzhou,Hongkong |

HONY®MC901 nylon plastic rod/bar MC Nylon,means Monomer Casting Nylon, is a kind of engineering plastics used in comprehensive industries, has been applied almost every industrial field

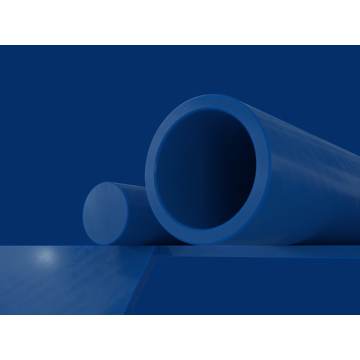

Overview: MC901 is a cast nylon plate, which has a striking blue color, which is more tough than ordinary cast nylon, has better flexibility and fatigue resistance. It is an ideal material for gears, racks and transmission gears.

Cast Nylon Sheet Tube and Rod Product features: high mechanical strength, stiffness, hardness, toughness, good aging resistance, good mechanical damping ability, good sliding properties, excellent wear resistance, good machining performance, no creep when used for precise and effective control , Good anti-wear performance, good dimensional stability.

MC PA6G Application: Widely used in chemical machinery and anti-corrosion equipment to make gears and parts with bad materials. Wear-resistant parts, transmission structure parts, household appliances parts, automobile manufacturing parts, screw preventive mechanical parts, chemical machinery parts, chemical equipment, etc.

Pa6G Sheet Rod including

1.Oil Nylon (Green color):

Excellent wear resistant, sliding frictional properties, abrasion resistance and stick slip performance, self-lubrication.

2.MC Nylon + MSO2(Light black color)

Impact-resistance and fatigue-resistance of casting nylon, strong loading capacity and wear-resistance.

It has a wide application in making gear, bearing, planet gear, seal circle and so on.

3. MC Nylon (Natural/White color):

High performance of wear-resistance, corrosion-resistance, self-lubrication, vibration-absorption, noise-absorption.

econocal cost, ideal substitutes of bronze, stainless steel, Babbitt alloy , PTFE and so on

It is suitable for making the bearing and other wear mechanical parts.

4.Oil MC901(Blue color)

Striking blue color, excellent toughness, flexibility, fatigue-resistance and so on.

It is the perfect material of gear, gear bar, transmission gear and so on.

5.Oil Nylon + Carbon (Black Color)

Very compact and crystal structure, high mechanical strength, wear-resistance, anti-aging, UV resistance and so on. It is suitable for making the bearing and other wear mechanical parts.

color: blue

Specification: Plate: Thickness×Width×Length 6-200mm×1000mm×2000mm

Bar: Diameter×Length 6-150mm×1000mm

HONY®MC901 Properties Data Sheet Mc Nylon Plate

| ITEM | METHOD | UNIT | VALUE |

| Mechanical Properties | |||

| Tensile yield strength | GB/T 1040 | MPa | 75-85 |

| Modulus of elongation | ISO 527 | MPa | 4100 |

| Breaking elongation | ISO 527 | % | >25 |

| Max. compressive strength | ISO 604 | MPa | 90-100 |

| Coefficient of compressibility | ISO 604 | MPa | 2700 |

| Bending strength | ISO 178 | MPa | 100-110 |

| Elasticiity bending modulus | ISO 178 | MPa | 3300 |

| Impacr strength | ISO 180 | KJ/M2 | 5.4 |

| Shore hardness | GB 3398 | Shore D | 83-85 |

| Thermal Properties | |||

| Melting point | ISO1218 | ℃ | 220 |

| Max. intermit operating temperature | - | ℃ | 180 |

| Max. continuous operating temperature | - | ℃ | 115 |

| Min. intermit operating temperature | - | ℃ | -100 |

| Min. cointinous operating temperature | - | ℃ | -40 |

| Coefficient of linear thermal expansion | ISO 11359 | 10-5-1/K | 5-8 |

| Electrical Properties | |||

| Dielectric constant | IEC 250 | - | 3.7 |

| Dielectric strength | IEC 243 | KV-mm | >25 |

| Volume resistivity | IEC 93 | Ω.cm | 1015 |

| Surface resistivity | IEC 93 | Ω | 1015 |

| Impedance | IEC 112 | - | CTI600 |

| Others | |||

| Specific gravity | USO 1183 | g/cm3 | 1.15 |

| Abrasive resistance | - | - | 0.41 |

| Coefficient | - | - | 0.39 |

Remark:

1."+" Tolerable , “-”Intolerable , "0" Depends on the situation

2. The above data is obtained from raw material test data, which is not completely consistent with the performance of the finished product, and the uniqueness of the data is not guaranteed

Main production

Package

Certificate

Our partner

Related Keywords