PA6 Nylon6 Rod Polyamide Plastics Bar

-

$3.901-99 Kilogram

-

$3.80100-999 Kilogram

-

$3.70≥1000 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | Enough |

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

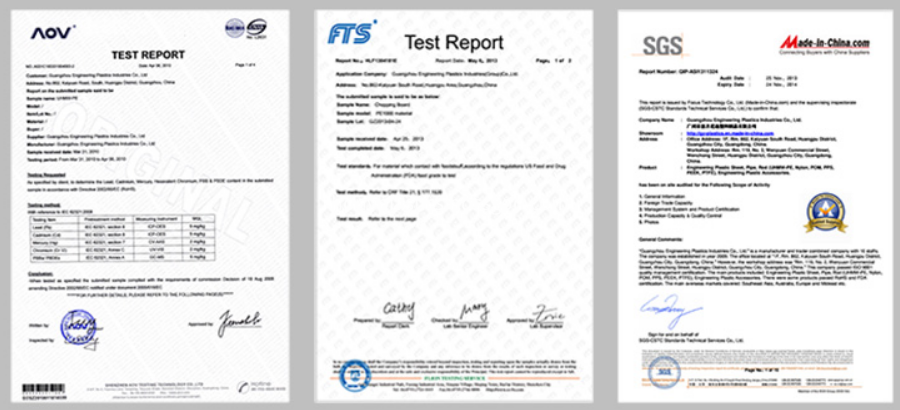

| Certificate: | SGS RoHS Reach ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

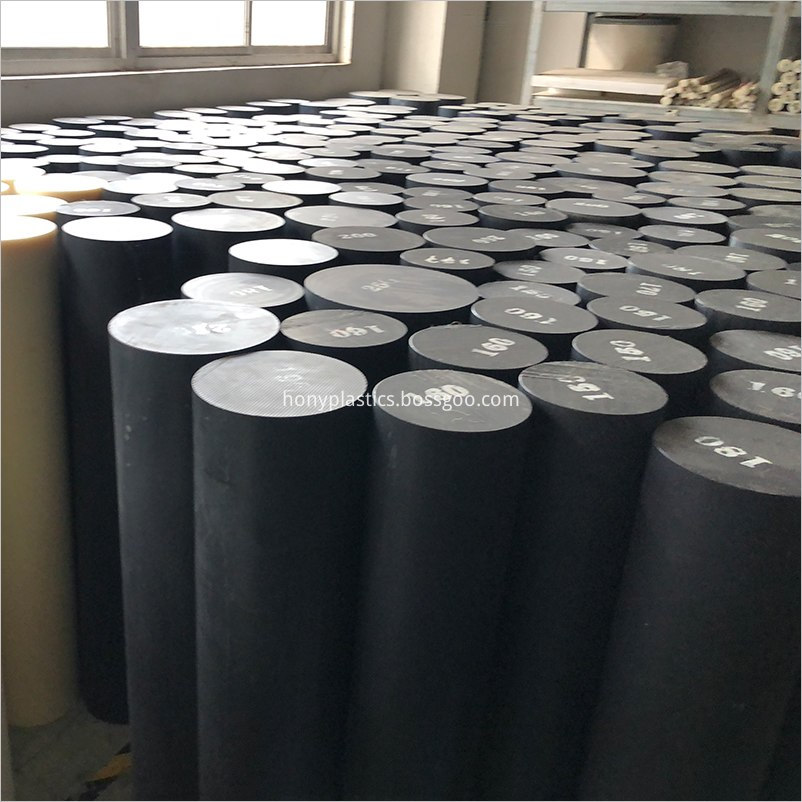

HONY®Customized Size solid Nylon Plastic Rods 100% Virgin PA6 Round Bar Engineering plastic extruded round nylon bar polyamide pa6 rod Round natural nylon bar plastic nylon rod with high tensile strength hollow virgin rod cast nylon colored PA6

PA6 is recognized as the most widely used and known engineering plastic in the current market. PA6 has the best performance, very tough, even at low temperatures, and high surface hardness, mechanical lower shock, and abrasion resistance. Combined with these characteristics and good insulation, and chemical properties, it has become common-level materials. It’s widely used in a variety of mechanical structures and spare parts. Compared to PA6, PA66 own the higher hardness, rigidity, better resistance to wear and heat deflection temperature

Product features: mechanical strength, rigidity, heat and wear resistance, good creep resistance, mechanical shock absorption performance, very suitable for automatic lathe machining

Product shortcomings: easy to absorb water, not resistant to ultraviolet rays, not resistant to strong acids and oxidants

Scope of application: automobile industry, electrical and electronic industry, transportation industry, machinery manufacturing industry, wire and cable communication industry, daily necessities, etc.

Application areas: bearings, gears, circular gears, cams, bevel gears, oil pipeline oil reservoir protection cover, support frame, wheel cover, deflector, fan air filter housing, radiator water chamber brake pipe, engine cover, Door handles, etc.

Color: beige, white, black, blue

Specification: Plate: Thickness×Width×Length 6-200mm×620/1000mm×1230/2000mm

Bar: Diameter×Length 6-200mm×1000/2000mm

Features:

1)High strength and stiffness

2)High impact and notch impact strength

3)High heat deflection temperature

4)Good at dampening

5)Good abrasion resistance

6)Low coefficient of friction

7)Good chemical stability against organic solvents and fuels

8)Excellent electrical properties, ease of printing and dyeing

9)Food safe, noise reduction

Application

Nylon Tube:Air, water, chemical lubrication, instrumentation lines, irrigation control systems, textile mills, food factories, fuel pipelines for vehicles and ships, vacuum systems, air conditioning systems, oscillating insulators, electrostatic insulators and other industries.

Nylon Rod:It is suitable for making wear-resistant parts, transmission structure parts, household electrical appliances parts, automobile manufacturing parts, screw rod preventive mechanical parts, chemical machinery parts, chemical equipment. Such as turbine, gear, bearing, impeller, crank, dashboard, drive shaft, valve, blade, screw, high-pressure gasket, screw, nut, sealing ring, shuttle, sleeve, sleeve connector, etc.

Nylon Board:Widely used in chemical machinery, anti-corrosion equipment gear and parts of bad materials. Wear-resistant parts, transmission structure parts, household electrical appliances parts, automotive manufacturing parts, screw preventive mechanical parts, chemical machinery parts, chemical equipment, etc.

| HONYNYLON PA Technical Data Sheet |

|

|

|

| Property item | Testing method | Unit | Testing data |

|

Mechanical properties |

|||

| Density | ASTM D792 | g/cm3 | 1.13 |

|

Tensile strength at yield |

ASTM D638 | Mpa | 74 |

|

Elongation at break |

ASTM D638 | % | 5 |

|

Bending strength |

ASTM 790 | Mpa | 90 |

|

Flexural modulus |

ASTM 790 | Mpa | 2200 |

|

Shore Hardness |

ASTM D2240 | D | 85 |

|

Impact strength |

ASTM D256 | J/M | 50 |

|

Thermal performance |

|||

|

Melting point |

DSC | ℃ | 220 |

|

Heat distortion temperature |

ASTM D648 | ℃ | 70 |

|

Long-term working temperature |

- | ℃ | 85 |

|

Short-term working temperature |

- | ℃ | 160 |

|

Thermal conductivity |

DIN 52612-1 | W/(K-M) | 0.23 |

|

Coefficient of linear expansion |

ASTM D696 | 10-5-1/K | 8 |

|

Electrical properties |

|||

|

Dielectric strength |

ASTM D150 | KV-mm | 25 |

|

Dielectric loss coefficient |

ASTM D150 | - | 0.032 |

|

Volume resistance |

ASTM D257 | Ω.cm |

1014 |

|

Surface resistance |

ASTM D257 | Ω |

1016 |

|

Dielectric constant |

ASTM D149 | - | 4.2 |

|

Chemical properties |

|||

|

Balanced water absorption |

23℃ 60%RH | % | 1.28 |

|

Acid resistance |

23℃ 60%RH |

|

- |

|

Alkali resistance |

|

|

+ |

|

Acid and alkali water resistance |

|

|

+ |

|

Chloric acid and alkali resistance |

|

|

0 |

|

Resistant to aromatic compounds |

|

|

+ |

|

Copper resistance |

23℃ 60%RH |

|

+ |

|

Hot water resistance |

23℃ 60%RH |

|

+ |

|

Other properties |

|||

|

Combustibility |

UL 94 |

|

HB |

|

Stickiness |

|

|

+ |

|

toxic free and safe |

EEC 90/128 FDA |

|

+ |

|

Coefficient of friction |

DIN 53375 |

|

0.36 |

|

anti-UV |

- |

|

0 |

Remark:

1."+" Tolerable , “-”Intolerable , "0" Depends on the situation

2. The above data is obtained from raw material test data, which is not completely consistent with the performance of the finished product, and the uniqueness of the data is not guaranteed

Main production

Color choose

Package

Certificate

Related Keywords