94V0 Flame Retardant Fr4 Epoxy Fiberglass Sheet

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

FR stands for flame retardant, and denotes that safety of flammability of FR4 is in compliance with the standard UL94V-0.

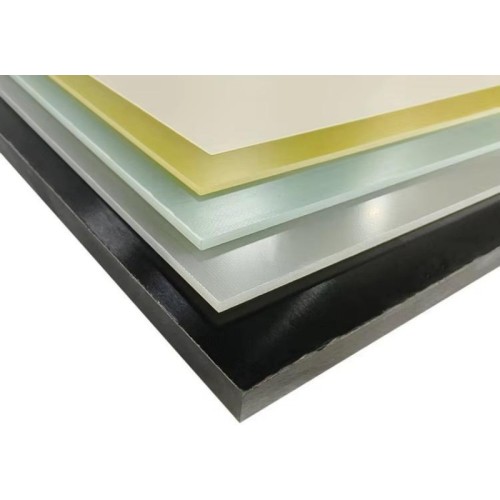

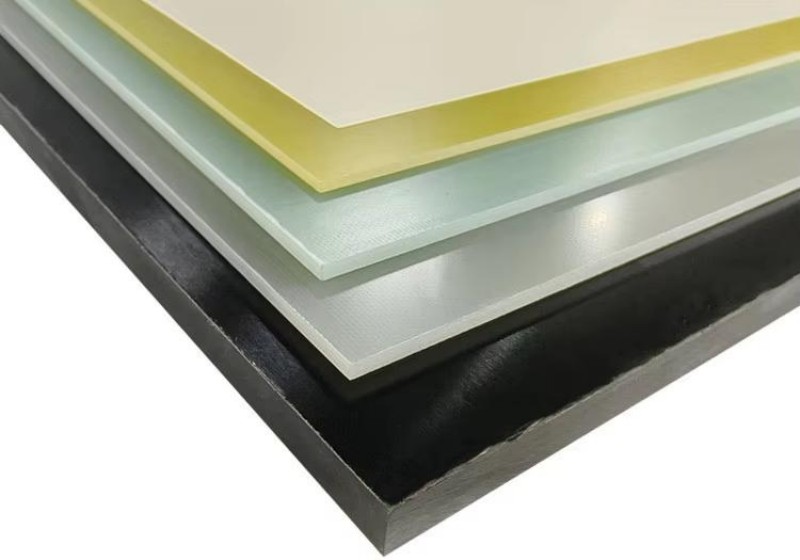

The FR4 epoxy laminate has a smooth surface, no air bubbles, no pits and wrinkles, but allows for other defects that do not affect the use, such as: scratches, indentations, stains and small spots. The edges should be cut neatly and the end faces must be free of delamination and cracks.

Characteristics: The FR4 sheet excellent mechanical properties, Plate properties: high temperature resistance. Electrical: The cured epoxy resin system is an excellent insulating material with high dielectric properties, surface leakage resistance and arc resistance.

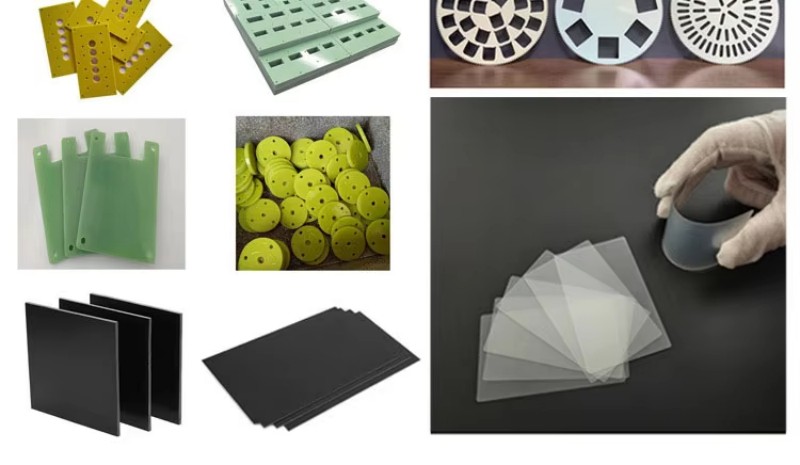

Uses: Suitable for mechanical, electrical, electronic,new energy and other fields. Also used for the processing of insulating parts, processing into various types of insulating parts and equipment insulation structural parts. The reaction of the epoxy resin and the curing agent used is carried out by a direct addition reaction or a ring-opening polymerization reaction of an epoxy group in a resin molecule, without the release of water or other volatile by-products. They exhibit very low shrinkage (less than 2%) during curing compared to unsaturated polyester resins and phenolic resins.

FR-4 Composite: Flame Retardant Electronic Material Characteristics and Applications

FR-4 is a composite material made of a blend of glass fibers and flame retardant epoxy resin, which is widely used in the manufacture of printed circuit boards (PCBs). Below are some of the key properties and uses of FR-4:

Properties:

- Flame Retardant: The “FR” in FR-4 stands for Flame-Retardant, which means that this material has flame retardant properties that can slow down the spread of fire and protect electronic devices from damage.

- Mechanical Properties: FR-4 has good mechanical properties, including tensile strength, compressive strength, flexural strength, and impact resistance, enabling it to withstand a wide range of loads and stresses in engineering applications.

- Thermal Stability: FR-4 has high thermal stability, allowing it to be used for long periods of time in higher temperature environments, as well as good dimensional stability.

- Electrical insulation properties: FR-4 has excellent electrical insulation properties, high insulation resistivity, low dielectric loss, and can maintain good insulation properties under high-voltage electric fields.

- Chemical resistance: FR-4 has good chemical resistance and can resist corrosion of most acids, alkalis, salts and other chemicals.

- Low Moisture Absorption: FR-4 material has a low moisture absorption rate of 0.01% when immersed in water for twenty-four hours.

- COST EFFECTIVE: FR-4 costs less than comparable products, making it an economical choice for manufacturers.

Uses:

- Electronics: FR-4 material is widely used in the manufacture of printed circuit boards (PCBs). Due to its good electrical insulation properties and thermal stability, the PCBs are able to maintain good performance at high temperatures and high pressures.

- Aerospace: In the aerospace field, FR-4 materials are used in the manufacture of aircraft interior parts, seat backs, fuselage frames and other components.

- Automotive field: In the automotive field, FR-4 materials are mainly used in the manufacture of automotive electronic components, hoods, body panels and other parts.

- Electrical industry: In the electrical industry, FR-4 materials are mainly used in the manufacture of high-voltage insulators, electrical insulation brackets, switch buttons and other components.

FR-4 has important application prospects in electronics, electrical appliances, aviation, automotive and other fields due to its excellent performance and wide range of applications.

Related Keywords

Related Keywords