Fr4 epoxy fiber glass sheet rod

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Certificate: | SDS RoHS |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

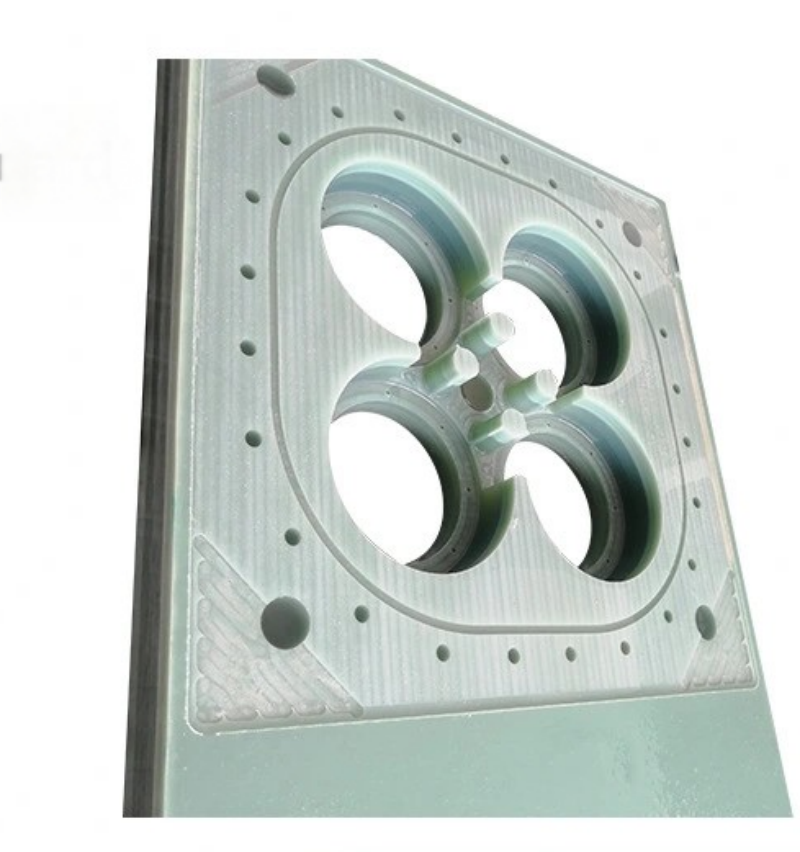

FR4 epoxy sheet: the cornerstone of the electronics industry

FR4 epoxy board, a common electronic substrate material, plays a vital role in the electronics industry. From smartphones to aerospace equipment, FR4 epoxy sheets are everywhere. This article will delve into the definition, properties, applications, and comparisons of FR4 epoxy boards with other materials, supplemented by graphics and tables to help readers gain a comprehensive understanding of this important material.

I. Introduction of FR4 epoxy board

FR4 epoxy board is a kind of composite material made of electronic grade glass fiber cloth impregnated with epoxy resin and then cured by high temperature and high pressure heat. Among them, “FR” stands for “Flame Retardant”, i.e. flame retardant grade, while “4” indicates the type of glass fiber cloth. FR4 epoxy board has good mechanical, electrical and processing properties, and is one of the most commonly used substrates for manufacturing printed circuit boards (PCBs).

Second, FR4 epoxy board performance

FR4 epoxy board is widely used, thanks to its excellent comprehensive performance:

1. Mechanical properties:

High strength: FR4 epoxy sheet has high mechanical strength and can withstand certain mechanical stress and impact.

Dimensional stability: FR4 epoxy sheet can still maintain good dimensional stability in high temperature and high humidity environment, not easy to deformation.

Abrasion resistance: FR4 epoxy board has smooth surface and good abrasion resistance, which can effectively extend the service life.

2. Electrical properties:

Insulation: FR4 epoxy board has good insulation properties, can effectively prevent current leakage.

Dielectric constant: FR4 epoxy board has a low dielectric constant, which can reduce the loss in the signal transmission process.

Arc resistance: FR4 epoxy board has good arc resistance and can withstand high voltage.

3. Processing performance:

Easy to process: FR4 epoxy board can be processed by drilling, milling, cutting and other ways, which is convenient to make PCBs of various shapes.

Good weldability: FR4 epoxy board surface is easy to weld, which can ensure the reliable connection of electronic components.

4. Other properties:

Flame retardant: FR4 epoxy board has good flame retardant properties, which can effectively prevent the occurrence of fire.

Chemical resistance: FR4 epoxy board can resist corrosion by most chemical solvents.

Third, the application of FR4 epoxy plate

FR4 epoxy board is widely used in a variety of electronic equipment, mainly including:

Consumer electronics: smart phones, tablet PCs, laptops, televisions, etc.

Communication equipment: base stations, routers, switches and so on.

Automotive electronics: engine control unit, body control module, car entertainment system, etc..

Industrial control: PLC, inverter, servo drive, etc.

Medical equipment: monitor, ultrasound diagnostic instrument, CT machine, etc.

Aerospace: Satellite, radar, navigation system, etc.

Comparison between FR4 epoxy board and other materials

In addition to FR4 epoxy boards, there are some other common PCB substrates, such as:

CEM-1/CEM-3: made of paper-based or glass fiber cloth impregnated with epoxy resin, lower cost, but not as good as FR4.

Aluminum substrate: aluminum plate as a substrate, with good heat dissipation performance, suitable for high-power LEDs and other occasions requiring heat dissipation.

Ceramic substrate: ceramic as a substrate, with excellent high temperature and corrosion resistance, suitable for high frequency, high temperature and other special environments.

V. Summary

FR4 epoxy board as a high-performance, widely used electronic substrate materials, in the electronics industry plays an irreplaceable role. With the continuous development of electronic technology, the performance requirements of PCB substrate are getting higher and higher. In the future, FR4 epoxy board will develop in the direction of high performance, multi-functionality, environmental protection, etc. to meet the growing market demand.

Related Keywords

Related Keywords