3240 epoxy glass cloth laminated sheet

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Certificate: | SDS RoHS |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

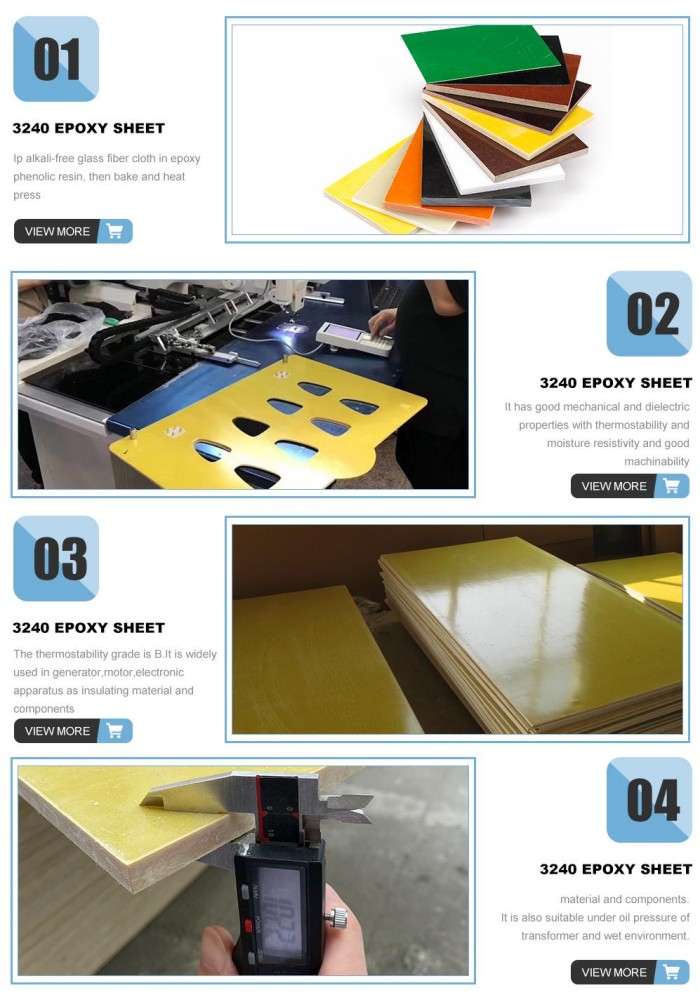

The surface of 3240 epoxy board laminate is required to be flat, free of bubbles, pockmarks and wrinkles, but other defects not affecting the use are allowed, such as: scuffs, indentations, stains and a small number of spots. The edges should be cut neatly, and the end face should not have delamination and cracks.

Execution standard: GB/T1303.1-1998 (native color), red, green and black are agreement standards.

Temperature resistance grade: B grade

Color: natural color (yellow), red, green, black, etc. (can be added, blended into a variety of colors)

Characteristics: The cured epoxy resin system has excellent mechanical properties, high strength under medium temperature, good stability of electrical properties under high humidity.

Electricity: cured epoxy resin system is a high dielectric properties, resistance to surface leakage, arc-resistant insulation materials

Uses: Suitable for mechanical, electrical, electronic, electrical appliances and other fields. Also used in the processing of insulating parts, processed into various types of insulating accessories and equipment insulation structure parts.

Thickness: 0.5 ~ 50mm under normal circumstances, can also be produced on request to 50 ~ 150mm thick plate.

The reaction of epoxy resin and curing agent used is carried out through direct addition reaction or ring-opening polymerization reaction of epoxy group in the resin molecule, and there is no water or other volatile by-products released. They show very low shrinkage (less than 2%) in the curing process compared to unsaturated polyester resins and phenolic resins.

Applications

The slot and wedge of the motor and the generator;

Insulation structure components of electrical equipment and transformers;

Print circuit board test fixture;

Needle board and carrier board in the field of electronic applications.

Industry standard: GB/T1303.1-1998 3240

What is the performance difference between FR4 epoxy sheet and 3240 epoxy sheet?

There are significant performance differences between FR4 epoxy board and 3240 epoxy board, and these differences are mainly in flame retardancy, color, environmental protection, dimensional stability, water absorption, and electrical and processing properties. The following is a detailed analysis of the difference between the two performance:

1.The flame retardant properties

FR4 epoxy board: excellent flame retardant properties, in line with the national UL 94V-0 standard, can be naturally extinguished in a fire, effectively slowing down the rate of spread of fire, to protect equipment and personnel safety.

3240 epoxy sheet: some products have flame retardant properties, but compared with FR4, its flame retardant grade may be lower or not have the same self-extinguishing ability.

2.Color and appearance

FR4 epoxy board: the color is natural, similar to the texture of jadeite or jade, translucent and bright, uniform tone.

3240 epoxy board: the color may be more flashing, does not look natural, and the uniformity of tone may not be as FR4.

3.Environmental protection

FR4 epoxy board: no radiation, in line with environmental requirements, in favor of sustainable development.

3240 epoxy board: some products may contain halogens, the environment and human health has a certain impact, less in line with environmental standards.

4.Dimensional stability

FR4 epoxy board: has good dimensional stability, better control of thickness tolerance in the pressing process, more suitable for precision processing and long-term use.

3240 epoxy board: although also has a certain degree of dimensional stability, but in contrast may be slightly inferior to FR4.

5.Water absorption

FR4 epoxy board: low water absorption, which provides a good help for its use in wet transformers and other equipment, reducing the performance decline caused by water absorption.

3240 epoxy board: data on its specific water absorption rate may vary from product to product, but usually not as good as FR4 performance.

6.Electrical properties

FR4 epoxy board: as an insulating material, its electrical properties are excellent, with a high dielectric constant and low dielectric loss, can effectively isolate the electric field, prevent current leakage.

3240 epoxy board: also as an insulating material, also has good electrical properties, but in some aspects may be slightly inferior to FR4.

7.Processing performance

FR4 epoxy board: a variety of forms, according to the need to adjust the resin, curing agent, modifier system, in order to adapt to different processing requirements. At the same time, its curing convenience, strong adhesion, low shrinkage, is conducive to the precise control of the processing.

3240 Epoxy Board: It also has good processing performance and is easy to cut, drill and molding operations. However, due to its slightly higher shrinkage than FR4, it may require more attention and adjustment during processing.

Related Keywords

Related Keywords