Fiberglass epoxy resin fr4 g10 rod

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, HongKong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | Enough |

|---|---|

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,DDP,Express Delivery |

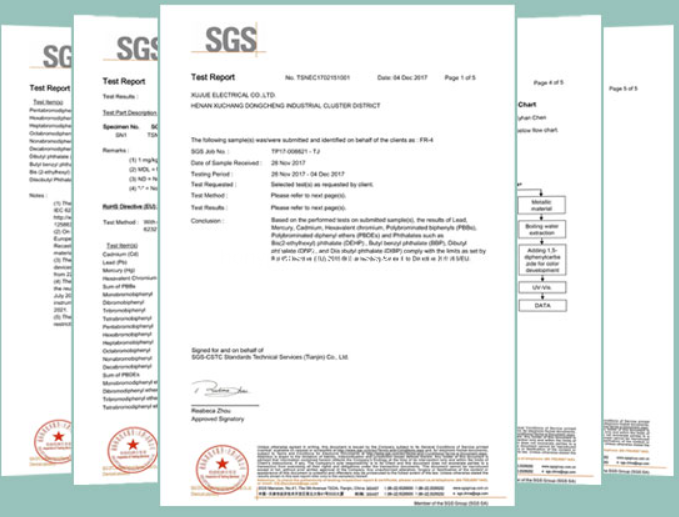

| Certificate: | SDS RoHS |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,HongKong |

FR-4 material, which is short for fiberglass cloth, it is a circuit board raw materials and substrates, flame-resistant material grade code, represented by the meaning of the resin material must be able to self-extinguish after combustion state of a material specification. It is most commonly used in PCB (Printed Circuit Board), generally single, double-sided and multi-layer PCB circuit boards are made of this! Because of its high strength and flame retardancy, FR-4 is chosen as the base material for most circuit boards.

Advantages of FR-4 and & Characteristics.

Typical single, double sided and multilayer PCB circuit boards are made from FR-4, the FR in FR-4 denotes flame retardant and the number 4 distinguishes the material from others in this category.FR-4 is a fiberglass reinforced epoxy laminate that looks like a thin woven fabric sheet. The term FR-4 also stands for the grade used to make these laminates. The fiberglass construction provides structural stability to the material. The fiberglass layer is covered with a flame retardant epoxy resin. This brings durability and strong mechanical properties to the material. All these properties make FR-4 printed circuit boards popular among electronic contract manufacturers.

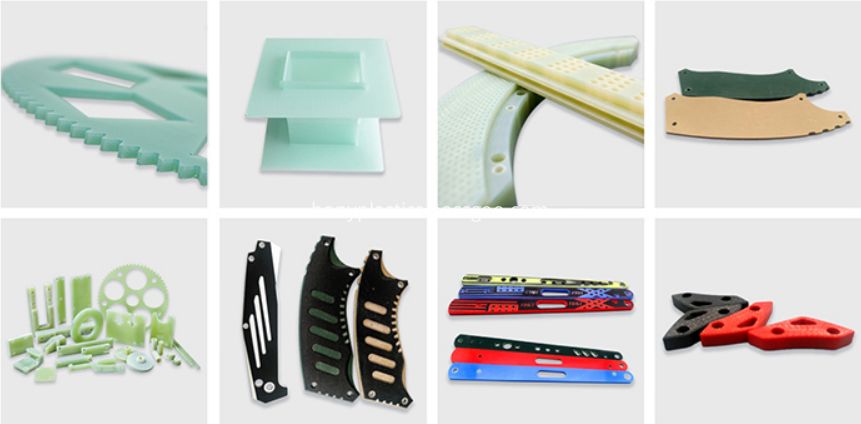

Its technical characteristics mainly lie in: electrical insulation, stable performance, good flatness, smooth surface, no pits, thickness tolerance standards, suitable for applications in high-performance electronic insulation requirements, such as FPC reinforcement boards, PCB drilling pads, fiberglass dielectrics, potentiometers carbon film printed fiberglass boards, precision vernier gears (wafer lapping), precision test panels, electrical (electrical) equipment insulation spacers spacer boards, insulation insulation board, transformer insulation board, motor insulation parts, grinding gears, electronic switch insulation board, and so on.

FR-4 sheet is now widely used in the military, communications, computers, digital circuits, industrial instruments, automotive circuits and other electronic products, the performance indicators can meet the needs of general industrial electronic products. There is a very good price-performance ratio.

HONY®FR4/G10 Technical Properties Data Sheet

| Standard | GB/T 1303-2009 / IEC60893-2003 | |||||

| Color | Natural/Green/Yellow/Black/Customizable | |||||

| IEC | EPGC201 | EPGC202 | EPGC203 | EPGC204 | EPGC206 | EPGC208 |

| NEMA | / | FR4 | G10 | FR5 | G11 | / |

| Density(g/cm3) | 1.8~1.95 g/m3 | |||||

| Vertical Layer Bending Strength(MPa) | ≥340MPa | |||||

| Parallel Layer Impact Strength(KJ/m2) | 38KJ/m2 | |||||

| Vertical Layer Electrical Strength(KV/m2) | ≥14.2Kv/mm | |||||

| Parallel Layer Breakdown Voltage(KV) | ≥35Kv | ≥35Kv | ≥40Kv | ≥35Kv | ≥40Kv | ≥35Kv |

| Dielectric Constant(50Hz) | ≤5.5 | |||||

| Delectric Loss Factor(50Hz) | ≤0.04 | |||||

| Insulation Resistance After Immersion(Ω) | ≥5.0*1010Ω | |||||

| Proof Tracking Index (PTI) | / | / | / | / | ≥200 | / |

| Combustibility | / | V-0 | / | V-0 | / | / |

| Temperature Index | 130 | 130 | 155 | 155 | 155 | 180 |

| Water Absorption(1-20mm Thickness) | 17~73mg | |||||

We are confidents to provide with CUSTOMIZED high quality Epoxy glass fiber Fr4/g10 products by our professional manufacturing team, manufacturing lines and experienced CNC router operators who have been engaged in this industry for more than 10 years.

Main Production

Machine

Package

Cerfication

Related Keywords