Black Fiberglass epoxy resin board FR4 G10 sheet

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, HongKong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | Enough |

|---|---|

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,DDP,Express Delivery |

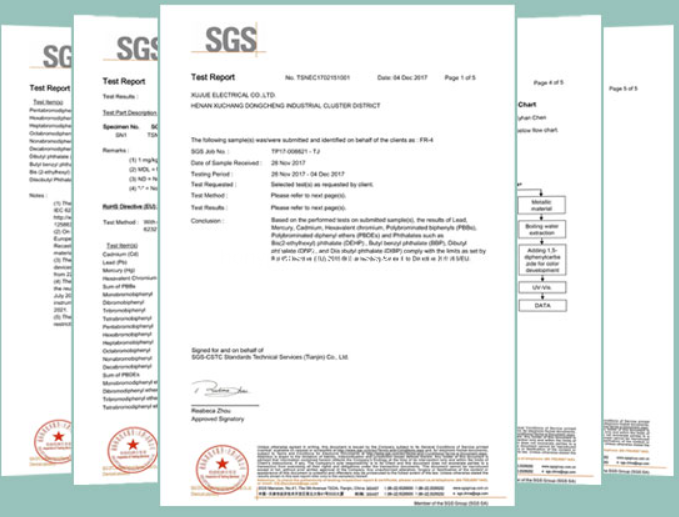

| Certificate: | SDS RoHS |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,HongKong |

Product introduction of black fr4 insulation board

Black fr4 insulation board, also known as fiberglass board, is generally used for soft package base layer, and then outside the package fabric, leather, etc., to make a beautiful wall, ceiling decoration. The application is very wide. With sound absorption, sound insulation, heat insulation, environmental protection, flame retardant and other characteristics.

Black fr4 insulating board is also known as fiberglass board; glass fiber board; FR4 reinforcement board; FR-4 epoxy resin board; flame retardant insulating board; epoxy board, FR4 light board; epoxy glass cloth board; circuit board drilling pad board.

Black fr4 insulating board alias: fiberglass insulation board, fiberglass board (FR-4), fiberglass synthetic board, synthesized by glass fiber material and high heat-resistant composite material, does not contain harmful asbestos composition. It has high mechanical and dielectric properties, good heat and moisture resistance, and good processability. It is used in plastic molds, injection molds, machinery manufacturing, molding machines, drilling machines, injection molding machines, motors, PCB, ICT fixtures, table grinding pads. Injection molding usually requires: high temperature material and low temperature mold. In the case of the same machine, heat insulation must be used. To keep the mold temperature low and not to make the injection molding machine temperature too high. This can be achieved by installing insulating panels between the mold and the injection molding machine. Shorten the production cycle, increase productivity, reduce energy consumption, improve the quality of finished products, continuous production process to ensure product quality and stability, to prevent overheating of the machine, no electrical failure, no oil leakage of the hydraulic system.

Black fr4 insulating board product characteristics

The main technical characteristics and applications of black fr4 insulating board: stable electrical insulation performance, good flatness, smooth surface, no pits, thickness tolerance exceeds the standard, suitable for use in high-performance electronic insulation requirements of the product, such as FPC reinforcement board, high temperature over tin furnace board, carbon film sheet, precision touring wheel, PCB test racks, electrical (electrical) equipment, insulating partition, insulating pads, insulating transformer parts, motor insulation pieces The black FRB is also known as the black FRB for the black color of the electric switches and the black FRB for the black color of the electronic switches.

It is also what we call black fr4 insulating board, which is generally used for soft package base layer, and then outside the package fabric, leather, etc., to make a beautiful wall and ceiling decoration. The application is very wide. With sound-absorbing, sound insulation, heat insulation, environmental protection, flame retardant and other features

HONY®FR4/G10 Technical Properties Data Sheet

| Standard | GB/T 1303-2009 / IEC60893-2003 | |||||

| Color | Natural/Green/Yellow/Black/Customizable | |||||

| IEC | EPGC201 | EPGC202 | EPGC203 | EPGC204 | EPGC206 | EPGC208 |

| NEMA | / | FR4 | G10 | FR5 | G11 | / |

| Density(g/cm3) | 1.8~1.95 g/m3 | |||||

| Vertical Layer Bending Strength(MPa) | ≥340MPa | |||||

| Parallel Layer Impact Strength(KJ/m2) | 38KJ/m2 | |||||

| Vertical Layer Electrical Strength(KV/m2) | ≥14.2Kv/mm | |||||

| Parallel Layer Breakdown Voltage(KV) | ≥35Kv | ≥35Kv | ≥40Kv | ≥35Kv | ≥40Kv | ≥35Kv |

| Dielectric Constant(50Hz) | ≤5.5 | |||||

| Delectric Loss Factor(50Hz) | ≤0.04 | |||||

| Insulation Resistance After Immersion(Ω) | ≥5.0*1010Ω | |||||

| Proof Tracking Index (PTI) | / | / | / | / | ≥200 | / |

| Combustibility | / | V-0 | / | V-0 | / | / |

| Temperature Index | 130 | 130 | 155 | 155 | 155 | 180 |

| Water Absorption(1-20mm Thickness) | 17~73mg | |||||

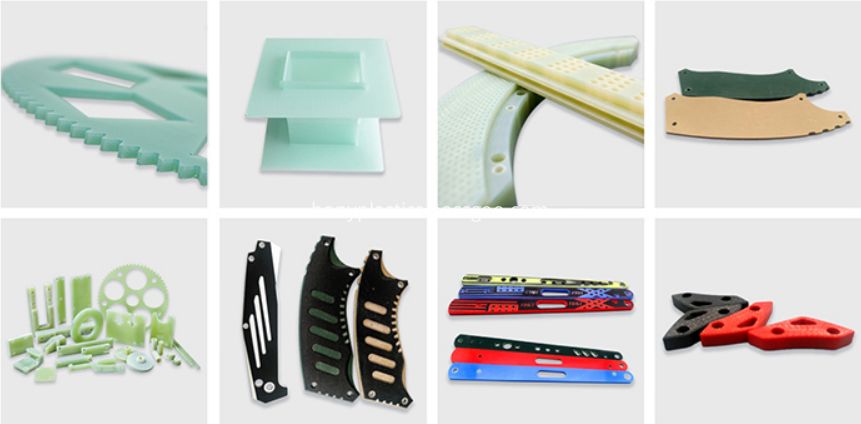

We are confidents to provide with CUSTOMIZED high quality Epoxy glass fiber Fr4/g10 products by our professional manufacturing team, manufacturing lines and experienced CNC router operators who have been engaged in this industry for more than 10 years.

Main Production

Machine

Package

Cerfication

Related Keywords