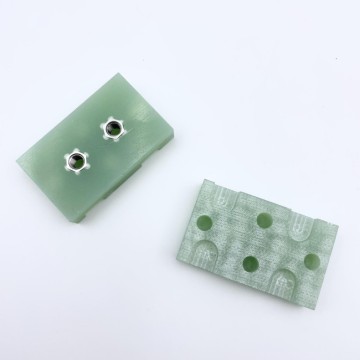

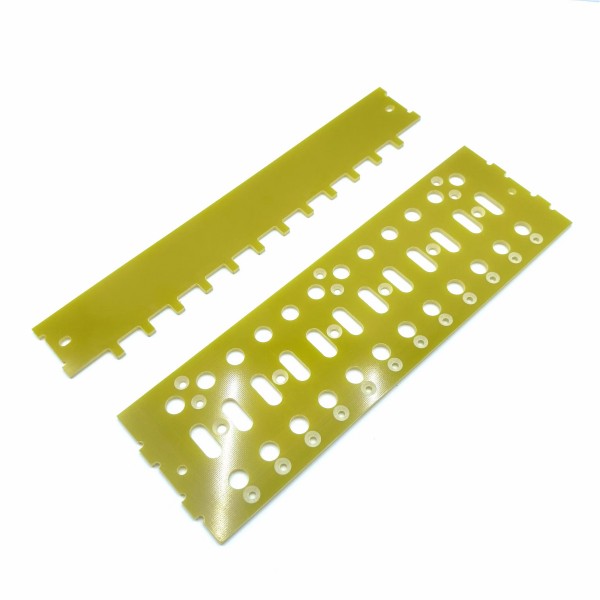

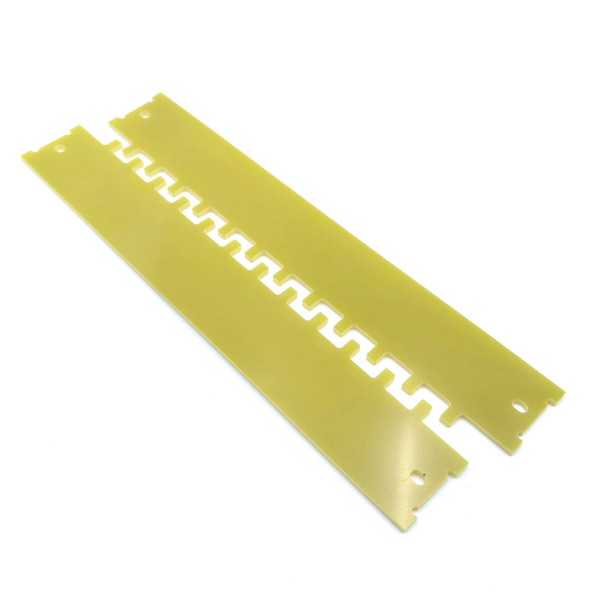

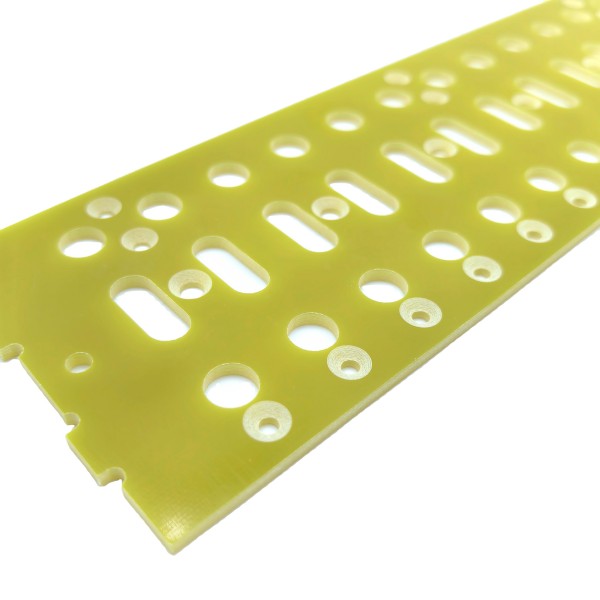

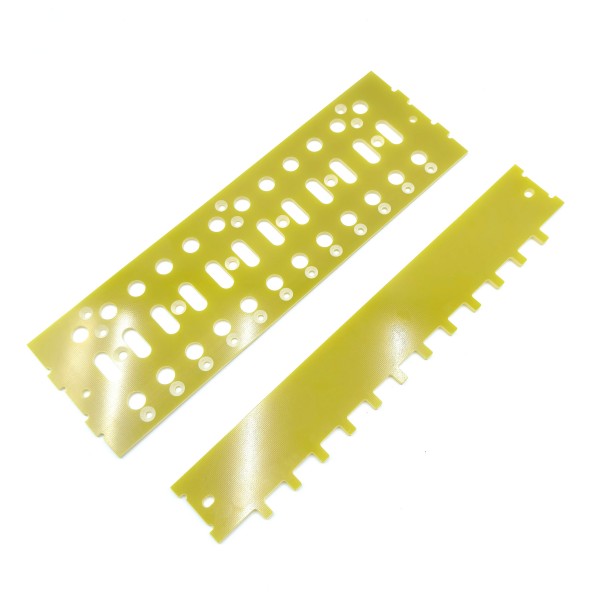

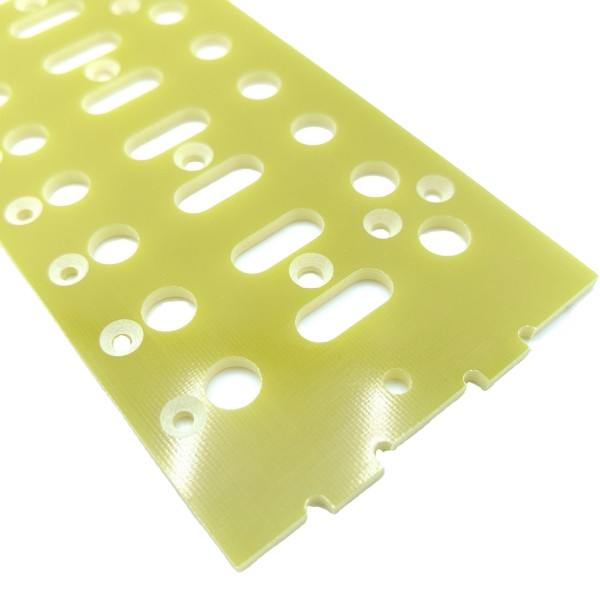

CNC Machining Parts G10 3240 Epoxy Fiberglass Boards

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,DDP |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

1. FR4 is a material classification widely used in the manufacture of printed circuit boards (PCBs), and it represents an epoxy resin system with specific properties, including a Tg (glass transition temperature) value of 125 degrees Celsius or more. In addition to FR4, there are other grades of materials such as FR1 and FR5.

2. In PCB materials, the so-called HTG (High Tg) and normal Tg (Normal Tg) refer to the different heat resistance properties of the material. HTG materials have a Tg value greater than or equal to 160 degrees Celsius, while normal Tg materials have a Tg value between 125 and 135 degrees Celsius. This directly affects the high temperature resistance of the material, which can be found in the IPC-4101B standard.

3. The glass fiber cloth models mentioned in the IPC-4101B standard, such as 106, 1080, 2113, 2116, 3313, 7628, etc., are mainly classified according to their thickness. These glass fiber cloths are used to enhance the bonding strength between layers in the PCB lamination process.

4. The main difference between high Tg and normal Tg materials is their Tg value, which directly determines their heat resistance. High Tg materials are usually used in high speed PCBs where high reliability is required, especially for high layer counts (more than 14 layers), while normal Tg materials are mostly used in 4 to 12 layer PCBs and automotive electronic boards. The application areas and performance characteristics of each material are different, the specific advantages and disadvantages are not listed. Related PCB materials can be found in Baidu library and other resources.

Related Keywords

Related Keywords