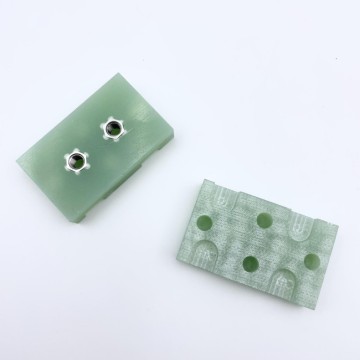

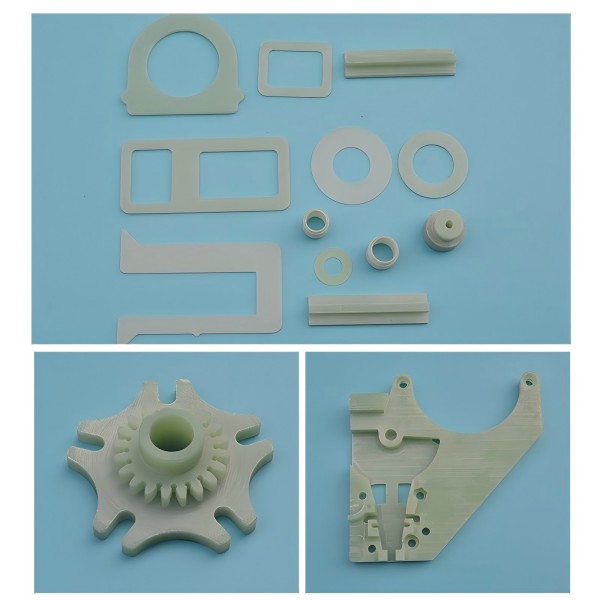

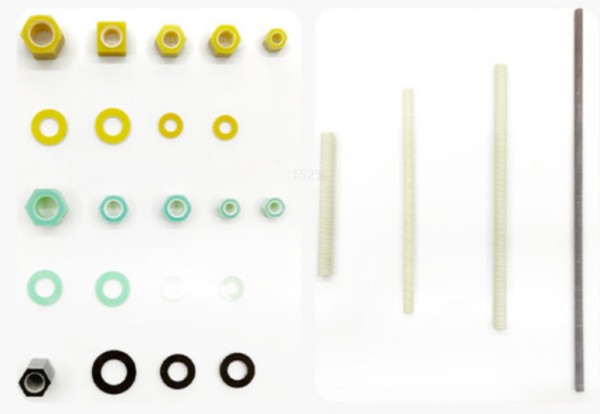

CNC Machining of Glass Fiber Epoxy Boards

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

The production process of epoxy sheet?

Raw material preparation: Prepare raw materials such as epoxy resin, curing agent and fiberglass cloth.

Pre-treatment: Pre-treat the fiberglass cloth, such as cleaning and drying.

Gluing: Mix epoxy resin and curing agent according to a certain proportion and stir well.

Impregnation: Immerse the pre-treated fiberglass cloth into the prepared glue to make it fully impregnated.

Lamination: Stack the impregnated fiberglass cloth and put it into the laminating machine for lamination, under certain temperature and pressure, make the epoxy resin curing and form the epoxy board.

Cooling: Remove the laminated epoxy sheet from the laminating machine and cool it down.

Cutting: The cooled epoxy sheet is cut into the required size and shape as needed.

Post-processing: Sanding, polishing and other post-processing on the cut epoxy sheet to improve its surface quality.

Quality inspection: carry out quality inspection on the produced epoxy boards, including appearance, size, performance and other aspects of the test.

Packing: Packing the inspected epoxy boards to protect them from damage during transportation and storage.

Maintenance and care of epoxy panels: recommendations for a longer service life

Epoxy panels are used in a wide range of applications due to their excellent properties, and proper maintenance and care is essential to extend their service life. The following are some suggestions for the maintenance and care of epoxy sheets.

First, epoxy boards should be stored in a dry, cool environment, away from direct sunlight and extreme temperature changes, which helps maintain the stability and performance of the material. Proper storage conditions will prevent premature aging or damage to the material.

Next, regular cleaning of the epoxy panel surface is key to keeping it in good condition. Wiping with a mild detergent and soft cloth can effectively remove dirt and stains, while avoiding hard or rough materials that may scratch the surface.

Surface scratches or damage to epoxy panels should be repaired promptly. A special epoxy resin repair agent can be used to repair a small area to prevent the damage from expanding and affecting the overall performance of the material.

In addition, epoxy boards should avoid prolonged exposure to corrosive chemicals during use. If contact with such substances is unavoidable, it should be cleaned immediately and dried thoroughly to prevent the material performance from deteriorating.

Finally, mechanical parts of epoxy boards, such as bearings or gears, should be inspected regularly for wear and tear, and necessary lubrication and adjustments should be made to ensure normal operation and prolong the service life of the equipment.

To summarize, through proper maintenance and care, the performance of epoxy sheets can be effectively maintained, thus extending their service life in various applications.

Related Keywords

Related Keywords