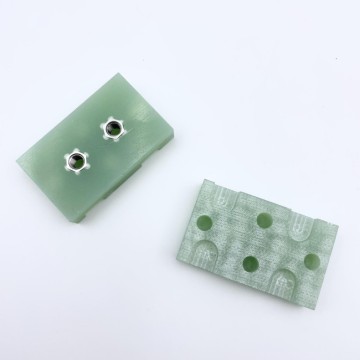

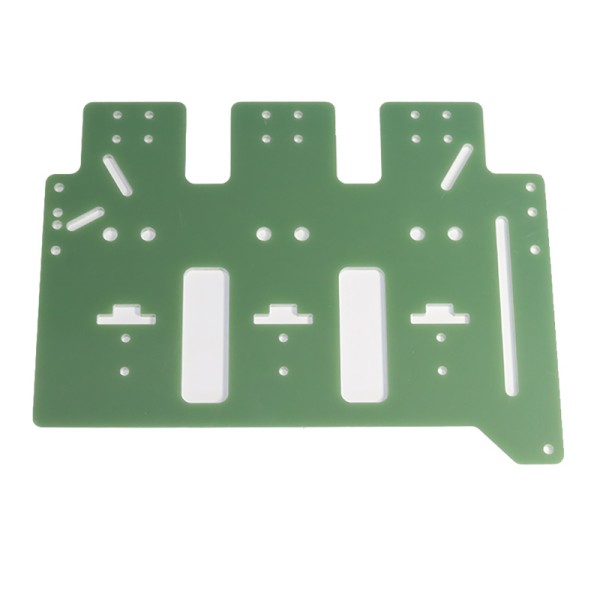

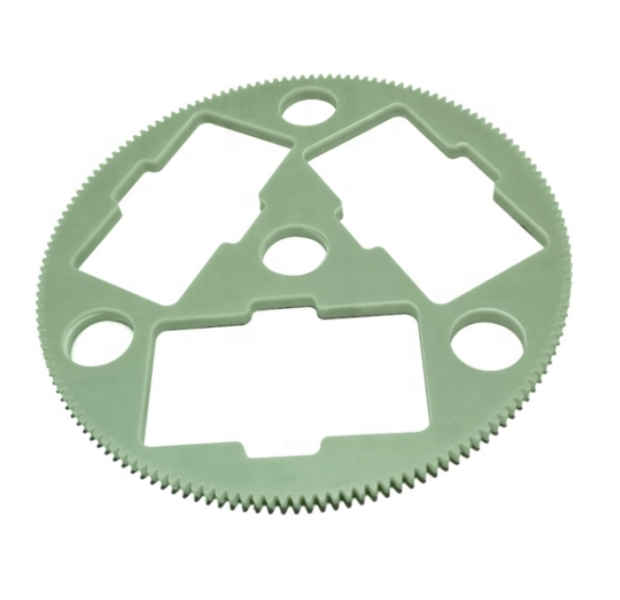

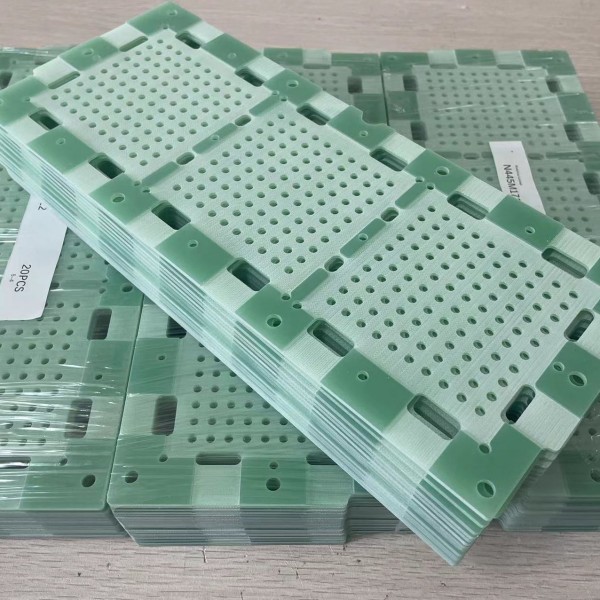

CNC FR4 machining parts epoxy resin board

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Express, Air

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Express,Air |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

The fr4 epoxy sheet processing is a code name for a flame-resistant material grade, which represents a material specification for a resin material that must be able to self-extinguish after a combustion state. Epoxy resin refers to organic polymer compounds containing two or more epoxy groups in the molecule, except for a few, their relative molecular mass is not high. The molecular structure of epoxy resin is characterized by the presence of active epoxy groups in the molecular chain, and the epoxy groups can be located at the end of the molecular chain, in the middle, or in a ring-like structure. As the molecular structure contains active epoxy groups, so that they can be with many types of curing agent crosslinking reaction and the formation of insoluble, non-molten polymers with a three-way network structure.

There are many models of fr4 epoxy board processing, the common ones are 3240, G11, G10, FR-4, etc. Their general performance is the same, they are all high-temperature-resistant insulating materials, the details are slightly different above, for example, the use temperature of FR-4 is around 130 ℃, while the use temperature of G11 can reach 180 ℃. So how is the performance? This article, talk about fr4 epoxy board processing conditions of use.

1, The use of epoxy board temperature of 120 degrees Celsius, a short period of time can be used in the environment of 130 degrees Celsius, more than this temperature will be warped, cracking can not be used.

2, It's good electrical properties, dielectric strength of 1000V/MIL, breakdown voltage of 65 kV, can be in the environment of high voltage and current continuous work.

3, It has strong mechanical processing, good mechanical ability, compressive strength of 303 MPa, tensile strength of 269 MPa, bending strength of 455 MPa, shear strength of 130 MPa. Can withstand strong external impact, good toughness.

4, Chemical properties, but also good, there is a certain degree of corrosion resistance.

5, For the non-flame retardant level, no bromine, in line with EU standards, environmental protection, will not pollute the environment, foreign use more.

As can be seen from the above, the performance of the epoxy plate is very good, it is made of epoxy resin bonded continuous filament woven fiberglass sheet, can be directly customized according to customer requirements, processing parts, if you come to the drawing board processing.

What are the processing methods of fr4 epoxy board? Then the following is a brief introduction to several common processing methods.

1, Drilling: this is a PCB circuit board factory common processing methods.

2, CNC technology: common point of processing is that it is CNC or numerical control, there are also called machining centers.

3, Cutting: general stores have a cutting board machine to cut the board with, and this is usually more rough, the tolerance of the large can be controlled within 5mm.

4, Milling machine / lathe: this processing method of processing out of the product, usually parts and components of such products.

Related Keywords

Related Keywords