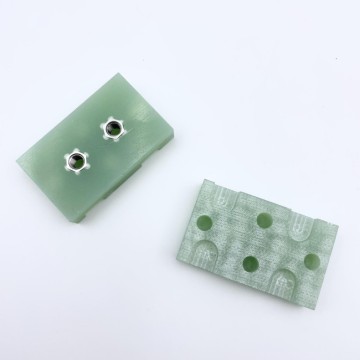

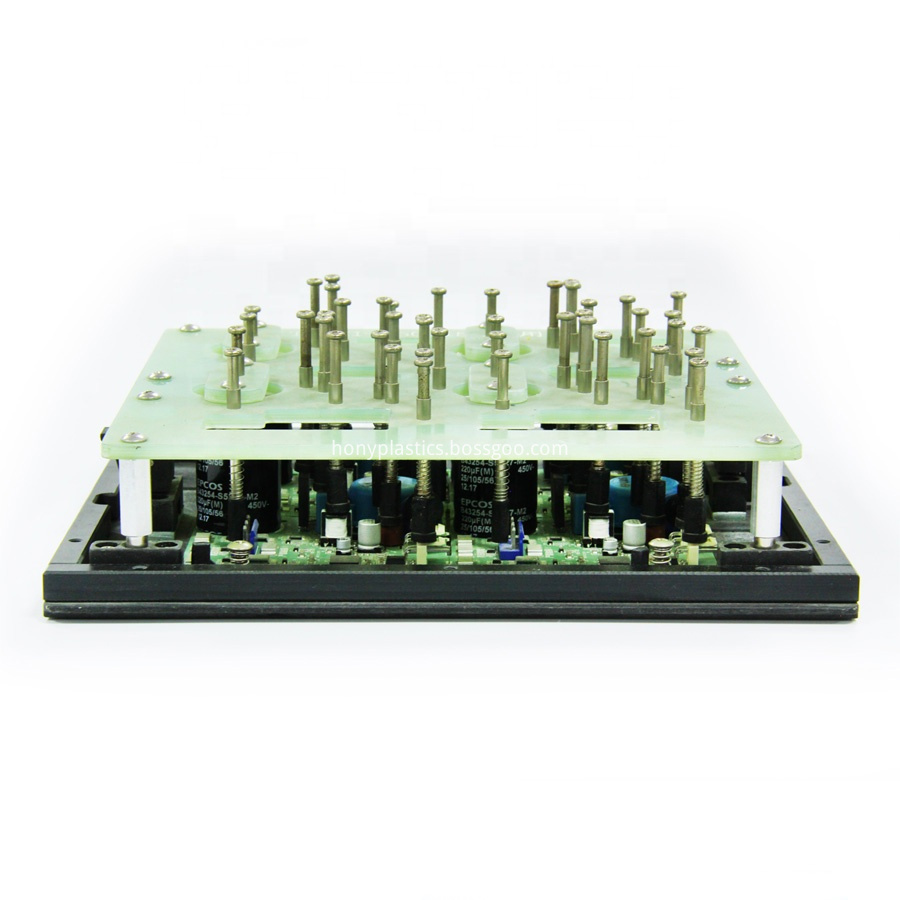

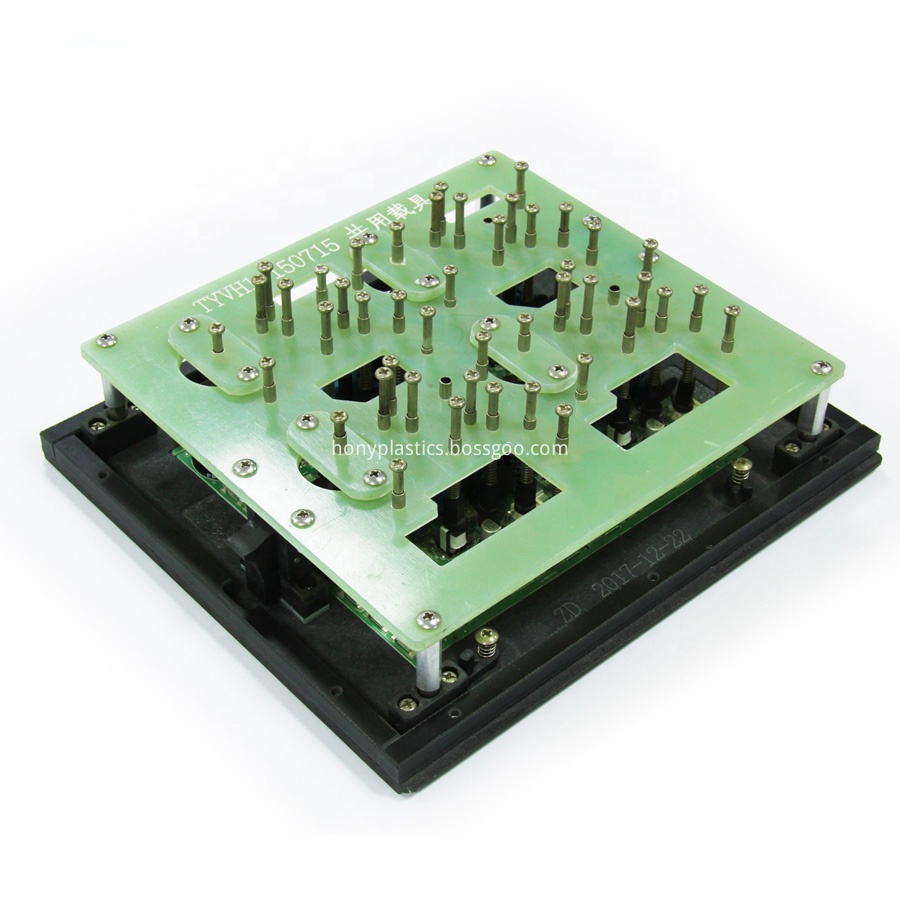

Wave soldering jig SMT jig FR4

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, HongKong

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 50000 pcs per day |

|---|---|

| Supply Ability: | Enough |

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Certificate: | SGS RoHS Reach ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,HongKong |

HONY®Wave soldering jig SMT jig PCB board bracket manual welding jig synthetic stone jig wave solder weld jig through furnace for pcb

FR4 glass fiber is a heavy-duty glass fiber reinforced plastic with high strength and excellent electrical, thermal and chemical properties. Continuous use at 280 ° c (maximum) temperature to maintain mechanical strength, finish and primary color. Operating temperature below 385 degrees 10~20 seconds).

In addition, synthetic stone with easy processing, high strength, can be processed into special mechanical parts and other advantages.

Features:

1. Normal working temperature is 280℃, and the highest working temperature is 384℃

2. Small deformation and low thermal conductivity

3. Good dimensional stability and long service life

4. High temperature resistance

5. Chemical corrosion resistance

6. High mechanical strength

7. Good processability (low density)

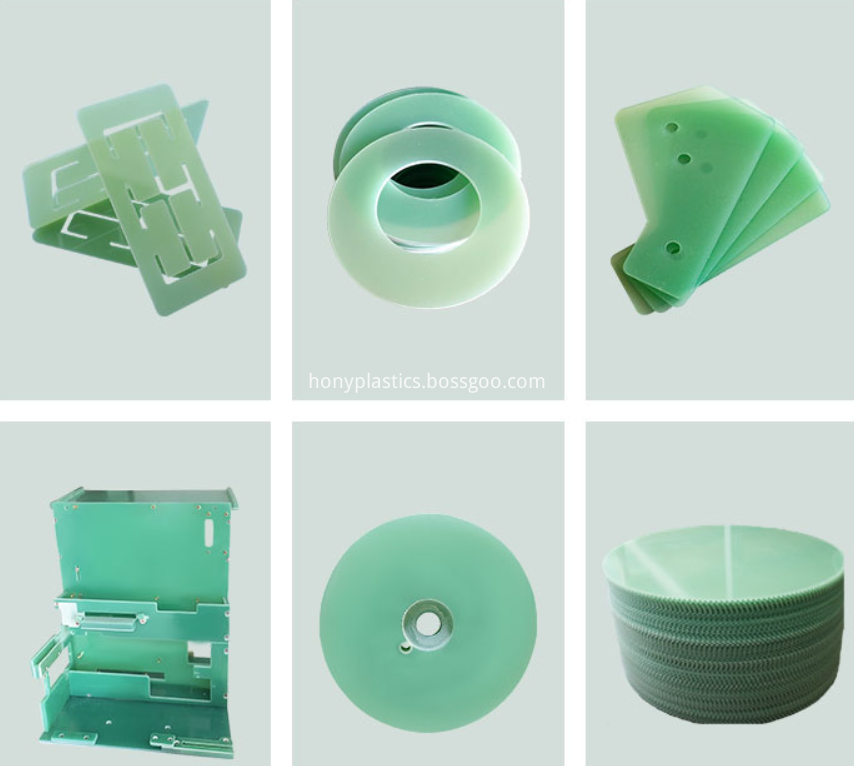

Epoxy Sheet, also known as insulation sheet, fiberglass sheet, and Epoxy sheet, it is made of alkali-free E-glass cloth impregnated with epoxy resins by processing under heat and pressure. It owns the character of high temperature resistance, High-intensity, Flame-retardant grades to UL94-V0, high mechanical properties and dielectric properties, good heat resistance, good-smoothness, etc.

Product Type: Epoxy fiberglass laminate sheet

Material: Flame- Retardant Epoxy Resin + Fiber glass Fabric

Product Features:

1. The flame retardant grade is UL94 V0

2. F grade Heat resistance and heat resistance (120 min) reaches to 180 ℃

3. High mechanical performances (bending, compression and stretching of transverse strength is above 330Mpa)

4. High dielectric properties of th e oil (25 ℃ in the vertical dielectric strength of 16 kv/mm).

5. We can press, cut and process the sheet according to customer's requirements and provide insulation accessories directly.

Product Application:

Motor control, communication equipments

Separator between the magnetic ring inductors and the base of the bottom

Thermal power devices

Also suitable for high voltage transformer and switch cabinet, high temperature, high-power welder even in wet environment

NOTE:

(1)Enough stock of raw Fr4 epoxy fiberglass board

(2)Cutted into small pieces

(3)CNC router machine programming

(4)OEM products weighted on electronic balance

(5)Products sealed in transparent PE bags

(6)Cartons of Fr4 products ready to be delivered

HONY®FR4/G10 Properties Data Sheet

Standard

GB/T 1303-2009 / IEC60893-2003

Color

Natural/Green/Yellow/Black/Customizable

IEC

EPGC201

EPGC202

EPGC203

EPGC204

EPGC206

EPGC208

NEMA

/

FR4

G10

FR5

G11

/

Density(g/cm3)

1.8~1.95 g/m3

Vertical Layer Bending Strength(MPa)

≥340MPa

Parallel Layer Impact Strength(KJ/m2)

38KJ/m2

Vertical Layer Electrical Strength(KV/m2)

≥14.2Kv/mm

Parallel Layer Breakdown Voltage(KV)

≥35Kv

≥35Kv

≥40Kv

≥35Kv

≥40Kv

≥35Kv

Dielectric Constant(50Hz)

≤5.5

Delectric Loss Factor(50Hz)

≤0.04

Insulation Resistance After Immersion(Ω)

≥5.0*1010Ω

Proof Tracking Index (PTI)

/

/

/

/

≥200

/

Combustibility

/

V-0

/

V-0

/

/

Temperature Index

130

130

155

155

155

180

Water Absorption(1-20mm Thickness)

17~73mg

We are confidents to provide with CUSTOMIZED high quality Epoxy glass fiber Fr4/g10 products by our professional manufacturing team, manufacturing lines and experienced CNC router operators who have been engaged in this industry for more than 10 years.

The company undertakes the processing of insulating material parts, bakelite parts, epoxy board parts, PCB test stand, wave soldering fixture, furnace welding fixture, ICT / FCT fixture, SMD fixture, non-standard fixture fixture processing customization, single piece or batch, welcome to call for consultation. This product belongs to customized parts, and the price needs to be determined according to the specific drawing requirements. If you have any demand, please contact our shop first to determine the design scheme and the quotation before shooting

Main Production

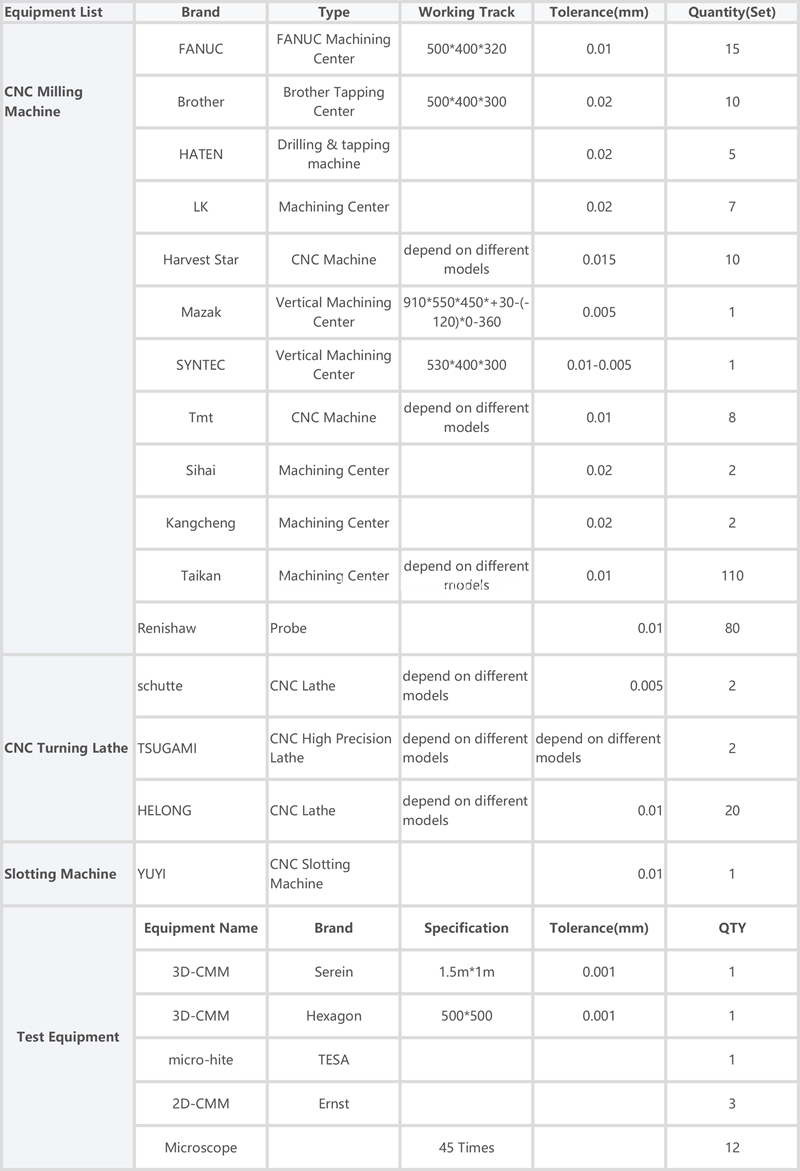

Our machine list

Machine

Package

Related Keywords