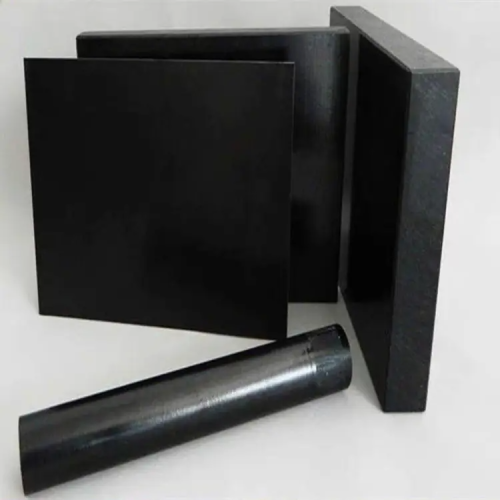

Polyethylene UHMW-PE ESD TIVAR 1000 antistatic sheets rods

-

$1.901-99 Kilogram

-

$1.80100-999 Kilogram

-

$1.70≥1000 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHENZHEN, GUANGZHOU, HONGKONG

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 100000 |

|---|---|

| Supply Ability: | 100000 |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,DDU |

| Certificate: | REACH ROHS ISO |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHENZHEN,GUANGZHOU,HONGKONG |

PE 1000 / PE-UHMW sheets - Antistatic ESD

This Polyethylene UHMW material comes with permanent antistatic properties. The electrostatic surface charge is strongly reduced, and a as a result the dust is not attracted and no electrostatic discharge occurs.

It addresses the increasing hygiene and safety requirements of the pharmaceutical and pharmaceutical processing industry, including compliance with GMP (Good Manufacturing Practice) handling requirements and compliance with ATEX Directive 94/9 / EC the ESD UHMW-PE was developed to be used in specific applications such as pill filling guidelines, drug pressing applications, pistons and powder dosing valves. It is also suitable for the food processing & packaging sector for sugar and flour processing linings, conveyor belt parts.

Esd Antistatic Uhmwpe Characteristics:

- Temperature: -200°C up to +80°C.

- Electrically conductive material and highly resistant to all kind of bending and impact.

- ESD UHMW-PE has great wear characteristics and chemical stability.

- Highly resistant to cold with no moisture absorption.

Esd Upe Plate Black Sheet Main Features:

- Minimal moisture absorption

- High impact strength

- Easy to machine

- Low friction rate

- ESD properties

| Yield stress | DIN EN ISO 527 | MPa | 22 |

| Elongation at break | DIN EN ISO 527 | % | >200 |

| Tensile modulus of elasticity | DIN EN ISO 527 | MPa | 700 |

| Notched impact strength | DIN EN ISO 179 | kJ / m2 | no break |

| Shore hardness | DIN EN ISO 868 | scale D | 63 |

| Melting temperature | ISO 11357-3 | °C | 135 |

| Thermal conductivity | DIN 52612-1 | W / (m * K) | 0,40 |

| Thermal capacity | DIN 52612 | kJ / (kg * K) | 1,90 |

| Coefficient of linear thermal expansion | DIN 53752 | 10-6 / K | 150 - 230 |

| Service temperature, long term | Average | °C | -150 … 80 |

| Service temperature, short term (max.) | Average | °C | 130 |

| Vicat softening temperature | DIN EN ISO 306, Vicat B | °C | 79 |

| Surface resistivity | DIN EN 62631-3-2 | Ω | 106 ... 109 |

| Density | DIN EN ISO 1183-1 | g / cm3 | 0,95 |

| Water absorption | DIN EN ISO 62 | % | <0,01 |

| Flammability (Thickness 3 mm / 6 mm) | UL 94 | HB | |

| Molecular weight | - | 106 g/mol | ~ 9 |

Related Keywords