ESD PVC sheet plate board

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

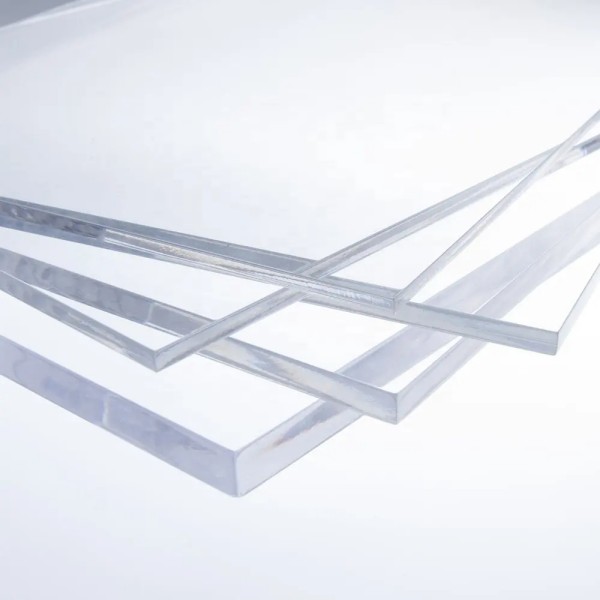

PVC is a polymerized substance of vinyl, and its material is a non-crystalline material.PVC materials are often used in practice with stabilizers, lubricants, auxiliary processing agents, colorants, anti-impact agents and other additives. It has non-flammability, high strength, climate change resistance and excellent geometric stability.PVC is highly resistant to oxidizing agents, reducing agents and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid and is not suitable for contact with aromatic and chlorinated hydrocarbons.

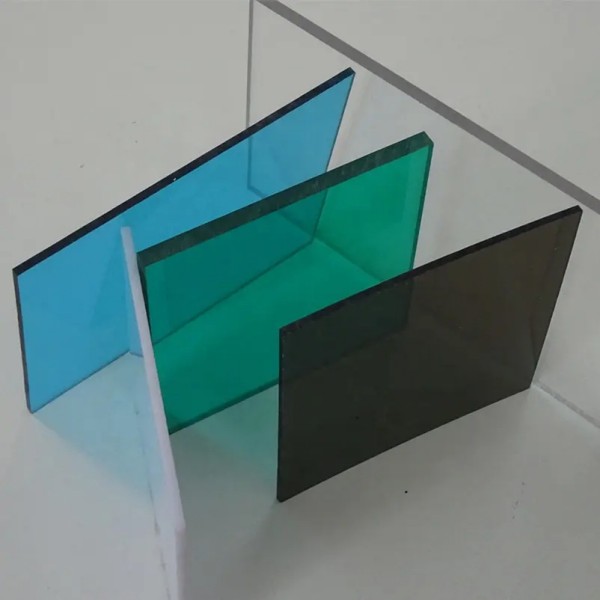

More commonly seen on the market antistatic PVC board is only the surface antistatic, is through the coating (Coating) technology, the formation of a layer of antistatic hard film on the surface of the PVC sheet (very thin, micron level, 1 mm mm = 1000 micron um), the antistatic layer can only be removed by mechanical processing methods, with alcohol chemical solvents to wipe also has no effect, this process is perfectly preserved This process perfectly retains the inherent transparent and beautiful characteristics of the plastic sheet, but also has the function of anti-static. It can effectively prevent the accumulation of dust and avoid the harm that may be caused by static electricity, in order to meet the special needs of the industry in the high-tech era.

Characteristics

Antistatic PVC board is characterized by good toughness, excellent impact resistance, chemical resistance, chemical resistance, weak acid, generally used more in LCD production equipment (due to the production of LCD will be weak acid chemical solution, etc.), in addition to the good flame retardant PVC board, fire prevention capabilities (flame retardant grade UL-94 V-0), good processing performance can be cold bending; weakness is the transparency of plexiglass and PC than the low ( 80% light transmission); PVC board poor environmental protection (production and use of environmental pollution, waste is difficult to degrade naturally), mainly used for equipment covers, dust room partitions, etc.. Transmission rate of 80%); PVC board environmental protection is poor (production and use of environmental pollution, waste is difficult to natural degradation), the main purpose of the equipment cover, clean room partition.

Duration

Antistatic function can last for more than 3-5 years generally, according to foreign manufacturers, foreign semiconductor factories generally 3-5 years will replace the antistatic plate, antistatic plate surface resistance after 3-5 years may gradually change to 7-9 times the ohm or a little higher; so foreign semiconductor factories in order to insure that the general 3-5 years will be replaced by antistatic plate.

Crafts

Anti-static Coating process (coating): anti-static liquid is brushed onto the surface of the sheet, and then dried under ultraviolet light; or the sheet is clamped in the air, so that the anti-static liquid is drenched onto the surface of the sheet under the action of gravity; the process is commonly used in China.

Anti-static non-Coating process (transfer type): anti-static film and plate molding, in order to avoid impurities in the air floating dust mixed into it, the whole process is completed in a sealed environment; due to the use of special technology, in the process of extrusion molding of the plate, anti-static film will be attached to the surface of the plate, after high temperature cooling and high pressure film, and finally tear off the film, so that the anti-static liquid evenly attached to the surface of the plate; Due to the complexity of the process, there is no domestic manufacturer using this process for the time being.

Main application

Application: Widely used in the construction of clean room plants (semiconductor, LCD, electronics, optics and pharmaceuticals, etc.), sheltering of clean room equipment, clean room space separation, clean equipment, observation windows and equipment covers, electronic test fixtures and so on.

Applicable industries: semiconductor industry, LCD industry, electronic equipment and microelectronic equipment industry, electrical and electronic, communication manufacturing, precision instruments, optical manufacturing, pharmaceutical industry and bioengineering and other industries.

Clean room equipment: all kinds of peep window materials, door materials, clean room partition walls, dust-free holes, partitions, air ducts, equipment enclosures, etc;

Mining and chemical equipment: reaction and absorption equipment, rare earth extraction tanks, electrolysis tanks, storage tanks, waste liquid treatment equipment, machine covers, etc;

Pharmaceutical equipment: aseptic filling equipment windows, pharmaceutical equipment enclosures, medicine tanks.

Related Keywords

Related Keywords