Semitron® ESD 500HR PTFE Polytetrafluoroethylene

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Semitron® ESD 500HR PTFE electrostatic dissipative shapes offer an excellent combination of low frictional properties, outstanding dimensional stability, and a high resistivity range of 10^10 to 10^12 ohms per square (antistatic range). Reinforced with a proprietary synthetic mica, Semitron® ESD 500HR PTFE is thermally stable up to temperatures of 500° F/260° C without degradation, possesses high thermal insulation, and a low coefficient of friction. Due to these characteristics, this grade is ideal for applications where controlled bleed-off of static charges is critical.

Key Properties

Surface Resistivity: 10^10 – 10^12 Ohms/Sq (Antistatic Range)

Thermal Performance To 500°F (260°C) Continous Use

Thermally Insulative

Very Low Coefficient of Friction

Broad Chemical Resistance

Low Outgassing Material

Total Mass Loss (TML%) .40%

Collected Volatile Condensable Materials (CVCM%) 0.00%

Water Vapor Regained (WVR%) 0.01%

ESD PTFE sheet Limitations

High Loads

Subject to Creep, Cold Flow

Thermal Expansion

Tight Tolerance Applications

antistatic PTFE rod Available Geometries

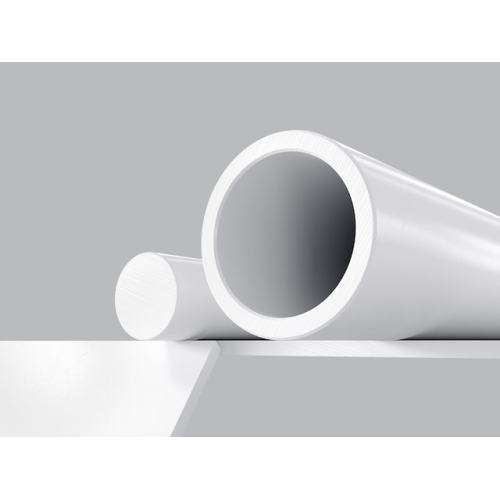

Semitron® ESD 500HR PTFE stock shapes encompass a range of standard sizes in the following geometries: Rod, Plate, Tubular bar

ESD antistatic PTFE sheet rod Applications

Circuit Boards

Components for High Speed Electronic Printing

Hard Disk Drives Components

Integrated Circuits Components

Photovoltaic Processing Equipment

Sensitive Processing Components in a Wide Range of Semiconductor Processes

Typical Properties of Semitron ® ESd 500 HR PTFE

| DETAIL | |||

|---|---|---|---|

| Description | Value | ||

| Material Type | Semi-Crystalline Thermoplastic Fluoropolymer | ||

| Chemical Name | PTFE Polytetrafluoroethylene | ||

| Trade Name | SEMITRON® ESD 500HR | ||

| Additives | Proprietary Additives | ||

| Color | White | ||

| Manufacturer | Quadrant | ||

| PHYSICAL | |||

| Property | Test | Unit of Measure | Value |

| Density | ASTM D792 | g/cm³ | 2.3 |

| ASTM D792 | lb/in³ | 0.083 | |

| Water Absorption, 24 hrs, Immersion | ASTM D570 | % by wt. | 0.03 |

| MECHANICAL | |||

| Property | Test | Unit of Measure | Value |

| Tensile Strength | ASTM D638 | psi | 1100 |

| Tensile Modulus | ASTM D638 | psi | 300000 |

| Tensile Elongation at Break | ASTM D638 | % | 50 |

| Flexural Strength | ASTM D790 | psi | 2200 |

| Flexural Modulus | ASTM D790 | psi | 500000 |

| Compressive Strength | ASTM D695 | psi | 4000 |

| Compressive Modulus | ASTM D695 | psi | 250000 |

| Hardness | ASTM D785 | NA | Rockwell R50 |

| IZOD Impact-Notched | ASTM D256 | ft-lb/in | 1 |

| THERMAL | |||

| Property | Test | Unit of Measure | Value |

| Coefficient of Linear Thermal Expansion | ASTM D696 | x 10-5 in./in./°F | 5.7 |

| Heat Deflection Temp | ASTM D648 | °C at 264 psi | 132 |

| ASTM D648 | °F at 264 psi | 270 | |

| Melting Point Temp | ASTM D3418 | °C | 327 |

| ASTM D3418 | °F | 621 | |

| Max Continuous Operating Temp | °C | 260 | |

| °F | 500 | ||

| Minimum Operating Temp | °C | -200 | |

| °F | -328 | ||

| Thermal Conductivity | ASTM C117 | BTU-in/ft²-hr-°F | 5.3 |

| ASTM C117 | x 10^4 cal/cm-sec-°C | 18.3 | |

| Flammability Rating | UL94 | NA | V-0 |

| ELECTRICAL | |||

| Property | Test | Unit of Measure | Value |

| Dielectric Strength | ASTM D149 | V/mil | 390 |

| Dielectric Constant at 1 MHz | ASTM D150 | NA | 2.9 |

| Surface Resistivity | ANSI/ESD STM 11.11 | ohm/square | 10^9 - 10^11 |

| COMPLIANCE | |||

| Description | Value | ||

| FDA | No | ||

| USDA | No | ||

| NSF | No | ||

| 3-A Dairy | No | ||

| Canadian Food Inspection Agency | No | ||

| USP Class VI | No | ||

| OTHER | |||

| Description | Value | ||

| UV Resistant | Yes | ||

| Relative Cost | $$$$ | ||

| Machinability | 3 | ||

Related Keywords