Antistatic PEEK sheet - Hony Plastic

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou , Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 100 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou ,Hongkong |

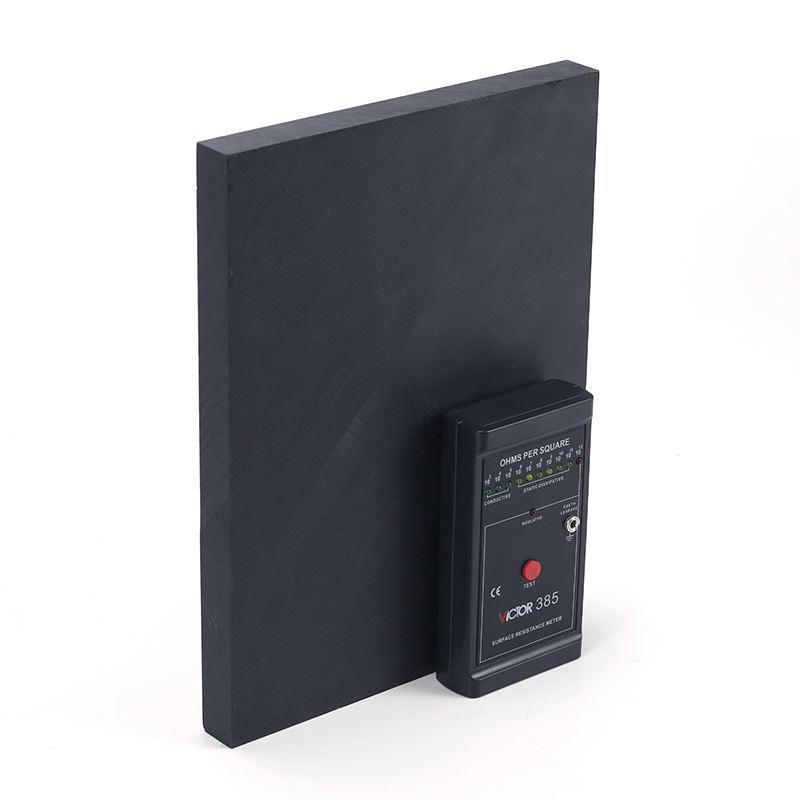

HONYESD®Antistatic PEEK Sheet and Rod- Hony Plastic

Esd Antistatic Peek Sheet: brown-gray material, high rigidity, good dimensional stability, small linear expansion coefficient, very close to metal aluminum material,Requirements for anti-static PEEK board: It has flame retardancy, releases less smoke and toxic gas under flame conditions, and meets the requirements of FDA food-grade materials.

Use of Esd Antistatic Peek Sheet: It has excellent chemical resistance. Among common chemicals, only concentrated sulfuric acid can dissolve or destroy it. Its corrosion resistance is similar to that of nickel steel.

Application of HONYESD®PEEK antistatic Sheet Rod: PEEK is widely used in aerospace, medical, semiconductor, pharmaceutical and food processing industries, such as gas splitter components and heat exchanger scrapers on satellites;

Antistatic Peek performance: Because of its superior friction performance, it becomes an ideal material in the field of friction applications, such as sleeve bearings, sliding bearings, valve seats, sealing rings, pump wear rings, etc.

HONYESD®PEEK antistatic Sheet Rod: various production parts, semiconductor liquid crystal manufacturing equipment parts, manufacturing jigs, atomic energy related parts, electronic components, various precision machine parts

PEEK Sheet Natural features:

1.The allowable working temperature is very high in the air (can work continuously at 260 degrees, and can reach 300 degrees in a short time); Good mechanical strength;

2.Rigidity;

3.High hardness;

4.High temperature resistance;

5.Good chemical resistance and Hydrolysis resistance;

6.Good wear resistance and friction properties,

7.High creep strength, good dimensional stability;

8.Good UV resistance and high energy radiation resistance;

9.Inherently low flammability;

10.Produces less smoke when burning.

Semitron®ESD 480 ESd PEEK application fields: used in semiconductor industry, LCD industry, electronic equipment and microelectronic equipment industry, electronics and electrical, communication manufacturing, precision instruments, optical manufacturing, bioengineering and other industries.

Related Keywords