Durostone®CFR767 – PCB Solder Pallet Materials

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 10000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,EXW,CIF,DDU,DDP |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Durostone CFR767 has excellent flux resistance. When fluxes containing halides or dicarboxylic acids are used in high-volume production, the lifetime of standard grade materials is reduced, so Durostone CFR767 is the ideal solution.wave soldering tray durostone

Durostone® CFR767 for harsh environments durostone

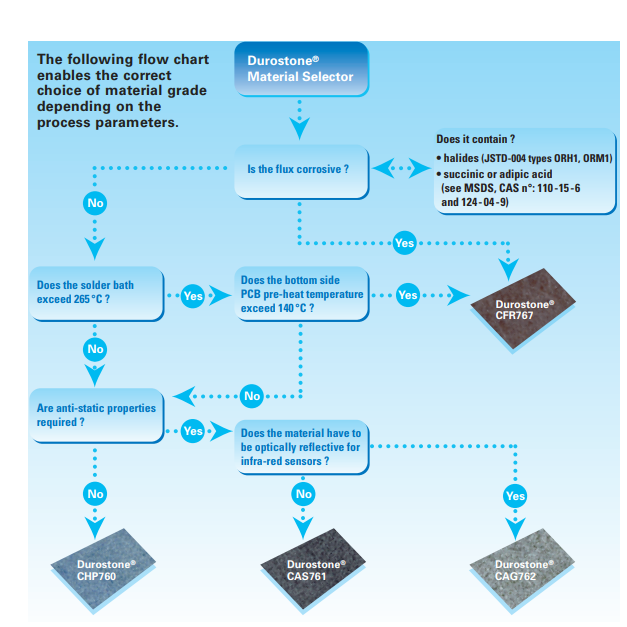

A combination of flux, temperature and process cycling can cause degradation of FO standard Durostone grade material.

The solution is Durostone® CFR767 which has been specially formulated for use with aggressive fluxes and high processes.durostone

For the production of Durostone CFR767 Wave Soldering Tray Synthetic Stone resin can withstand temperatures up to 300 ℃. Use one of the standard grades of Durostone CFR767 when the solder bath temperature exceeds 265°C and the bottom side of the PCB is preheated above 140°C. by the decision

Durostone CFR767 Durostone Pcb Wave Pallet has excellent solder flux resistance. When halogenated or dicarboxylic acid fluxes are used in high volume production, the lifetime of the standard grade material can be reduced so Durostone CFR767 is the ideal solution wave solder pallets

Features of Durostone® CFR 767:

Excellent flux resistance

Can withstand temperatures up to 300°C

excellent chemical resistance

Brown

Coefficient of linear Expansion(10-6/K) beteen 30℃ & 200℃

Technical Data

CHO760

CAS761

CAG762

CFR767

Grade

Standard

Anti-Static

Anti-Static Optical

Flux Resistant

Color

Blue

Black

Grey

Bordeaux(Red)

Density(g/m3)

1.90

1.90

1.90

1.80

Flexural Strength 3 point support (MPa)

@23℃

360

360

360

380

@150℃

180

180

180

260

@185℃

-

-

-

150

Modulus of Elasticity (MPa)

@23℃

18000

18000

18000

18000

@150℃

9000

9000

9000

14000

@185℃

-

-

-

10000

Water Absorption(%)

<0.20

<0.20

<0.20

<0.20

13

11

11

11

Thermal Conductivity (W/MK)

0.25

0.25

0.25

0.23

Maximum Operating Temperature(℃) 10-20 seconds

300

300

300

380

Standard Operating Temperature(℃)

260

260

260

300

Surface Resistivity(ohms)

-

105-109

105-109

105-109

Chemical Resistance

Good

Good

Good

Excellent

Sheet Size (mm)

2440 x 1220

Thickness available (mm)

3,4,5,6,8,10,12

5,6,8,10

Thickness Tolerance 3mm

-0/+0.10

Thickness Tolerance 4-12mm

-0/+0.20

Flatness Tolerance (for a panel size of 300 x 300)

0.20

Parallelism

0.10

All the values are average values

Material is considered as not electrostatic dissipative(ESD) if more than 5 measurements/m2

are insulative (1012 Ω. According to JEDEC standard JESD625B,a static dissipative material

is a material having a surface resistance between 104 and 1011 Ω

Related Keywords