Roechling WGR781 Durostone Anti-Static Composite Material

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shenzhen, Guangzhou, HongKong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | German |

|---|---|

| Supply Ability: | 1000 |

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU,DDP |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou,HongKong |

Durostone®WGR781 is a woven glass laminate specially designed to withstand extreme temperatures and aggressive fluxes.

Fluxes containing halides or halogen activators tend to shorten the life of common materials. In contrast, Durostone ® WGR781 will not have adverse effects even after thousands of cycles. The woven glass fiber layer can confirm that the flux will not invade the surface of the soldering mask, thereby exposing the glass fiber.

Antistatic durostone sheet used to manufacture Durostone ® WGR781 will not degrade even if it is used in continuous operation at a high temperature of 280°C. The material also has outstanding mechanical properties and can maintain the necessary dimensional stability even at the higher temperatures of the wave soldering process.

Durostone®WGR781 has outstanding processing performance, and its minimum wall thickness can be as low as 0.50mm.

Durostone®materials have been developed for all procedures within the PCB assembly prcosess,there are three main grades which are suitable for use in the SMT reflow and wave soldering processes. Durostone®CHP760,CAS761,CAG762, these materials offer the following features:

Excellent mechanical properties at elevated temperatures in both the wave soldering and SMT reflow processes

Low thermal conductivity

Excellent machining properties enabling the manufacture of complex design solder pallets

Good resistance to chemicals used in modern fluxes.

Durostone® WGR781 Antistatic durostone sheet

* Mixed technology PCB assembly designs have been changing the parameters of the wave soldering process in recent years.

* Solder pallet designs are becoming more complex, with thin walls <1.00mm and thick masking areas to cover tall bottom side SMT

components.

* Pb-free process temperatures are increasing as a result of the thicker masking.

* Pb-free fluxes containing halogen activators are damaging traditional epoxy-based

glass mat solder pallet materials due to the increased volumes applied.

* Thin walls machined in glass mat materials can have reduced lifespans due to the

random nature of the glass reinforcement and burning of the epoxy resin.

* Röchling Permali Composites has now developed a woven glass grade of solder pallet material which addresses the issues of

flux attack and thin wall damage.

Wave Soldering Tray Synthetic Stone Stock specifications:

Durostone Thickness 3mm.4mm.5mm.6mm.8mm.10mm.12mm

Size 1220*2440mm

Durostone®CAG762 Proterties Data Sheet

Material choose

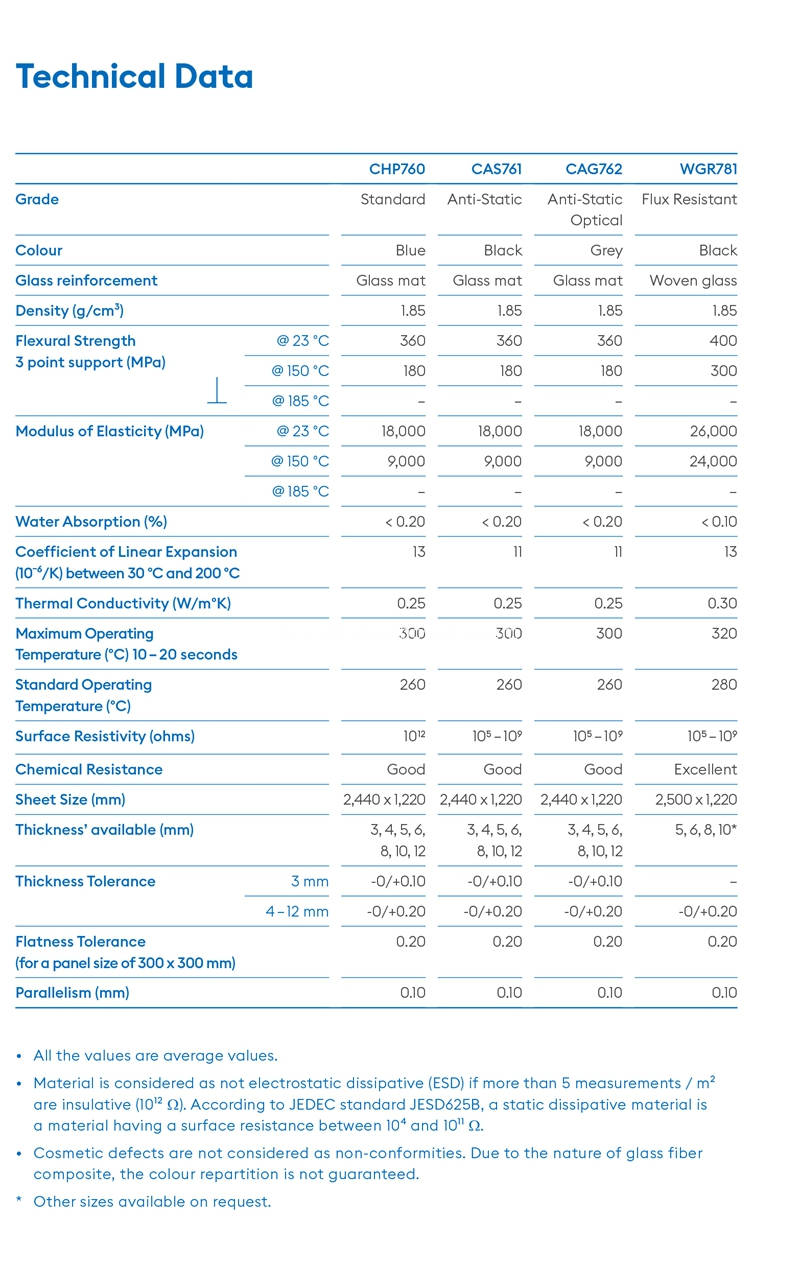

| Technical Data |

|

CHO760 | CAS761 | CAG762 | CFR767 |

| Grade |

|

Standard | Anti-Static | Anti-Static Optical | Flux Resistant |

| Color |

|

Blue | Black | Grey | Bordeaux(Red) |

| Density(g/m3) |

|

1.90 | 1.90 | 1.90 | 1.80 |

| Flexural Strength 3 point support (MPa) | @23℃ | 360 | 360 | 360 | 380 |

| @150℃ | 180 | 180 | 180 | 260 | |

| @185℃ | - | - | - | 150 | |

| Modulus of Elasticity (MPa) | @23℃ | 18000 | 18000 | 18000 | 18000 |

| @150℃ | 9000 | 9000 | 9000 | 14000 | |

| @185℃ | - | - | - | 10000 | |

| Water Absorption(%) |

|

<0.20 | <0.20 | <0.20 | <0.20 |

|

Coefficient of linear Expansion(10-6/K) beteen 30℃ & 200℃ |

|

13 | 11 | 11 | 11 |

| Thermal Conductivity (W/MK) |

|

0.25 | 0.25 | 0.25 | 0.23 |

| Maximum Operating Temperature(℃) 10-20 seconds |

|

300 | 300 | 300 | 380 |

| Standard Operating Temperature(℃) |

|

260 | 260 | 260 | 300 |

| Surface Resistivity(ohms) |

|

- | 105-109 | 105-109 | 105-109 |

| Chemical Resistance |

|

Good | Good | Good | Excellent |

| Sheet Size (mm) |

|

2440 x 1220 | |||

| Thickness available (mm) |

|

3,4,5,6,8,10,12 | 5,6,8,10 | ||

| Thickness Tolerance 3mm |

|

-0/+0.10 | |||

| Thickness Tolerance 4-12mm |

|

-0/+0.20 | |||

| Flatness Tolerance (for a panel size of 300 x 300) |

|

0.20 | |||

| Parallelism |

|

0.10 | |||

All the values are average values

Material is considered as not electrostatic dissipative(ESD) if more than 5 measurements/m2

are insulative (1012 Ω. According to JEDEC standard JESD625B,a static dissipative material

is a material having a surface resistance between 104 and 1011 Ω

Related Keywords