Processing bakelite Phenolic CNC part

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

Bakelite panels: the cost-effective material of choice

Bakelite, a sheet that combines excellent performance with a reasonable price, is used in a wide range of applications. Its unique physical and electrical properties make it the ideal choice for many projects. Whether it is used for electrical components or as a support material for mechanical structures, Bakelite meets the most demanding requirements. Its cost-effective characteristics, moreover, make it a sought-after product in the market.

Following the introduction of epoxy resin insulating boards in the previous issue, in this issue we will further explore another important material - bakelite boards. Bakelite board, with its excellent performance and reasonable price, is widely used in many fields. Its unique physical and electrical properties make it the preferred choice for many engineering projects. Whether it is the production of electrical components or the support of mechanical structures, Bakelite boards can easily cope with a variety of demanding challenges. Let's take a closer look at Bakelite.

Bakelite, a phenolic laminated paperboard made from bleached wood paddle paper through a special process, plays an important role in many fields with its excellent performance and reasonable price. During its production, phenolic resin is uniformly impregnated into the wood-paddle paper, which is then baked and hot-pressed, resulting in a material with outstanding physical and electrical properties. Whether it is used in the fabrication of electrical components or as a support for mechanical structures, bakelite panels exhibit excellent durability and stability.

Bakelite, also often referred to as gluewood or phenolic laminated paperboard, is one of the most widely used and heavily utilized laminates in industry. It is available in red, orange and black colors and is made with high quality bleached woodfree paper and cotton flannel paper as reinforcement materials. At the same time, the use of phenolic resin, which is made by reacting high-purity, fully synthetic petrochemical raw materials, as the resin binder ensures that Bakelite has excellent physical and electrical properties.

Bakelite board plays an important role in the field of electronic products due to its excellent insulating properties, static-free generation, abrasion resistance and high temperature resistance. It is often used as a material for insulated switches, variable resistors, and also in mechanical molds and production line fixtures. In addition, bakelite boards can be used in transformer oils, demonstrating their wide applicability. It is important to note that because bakelite is a synthetic chemical, once it is heated and molded, it solidifies and cannot be reshaped. However, this gives it excellent properties such as non-absorbent, non-conductive, high temperature resistance and high strength, making it widely used in the manufacture of electrical products.

Characteristics of Bakelite

Bakelite, as a man-made synthetic chemical, has a number of outstanding properties. First of all, its excellent insulating properties make it play a key role in the manufacture of electronic products, and it is often used in the manufacture of insulated switches and variable resistors. In addition, Bakelite is static-free, ensuring that no static electricity is generated during use, further enhancing its safety. At the same time, its abrasion resistance and high temperature resistance make it stable in mechanical molds and production line fixtures. In addition, it is worth mentioning that bakelite can also show good applicability in transformer oil, which further broadens its scope of application.

Bakelite performs well at room temperature and has excellent electrical properties, as well as good machinability and mechanical strength. It is also anti-static and has intermediate electrical insulation. With a specific gravity of 1.45 and a warpage of no more than 3‰, Bakelite panels exhibit excellent properties in electrical, mechanical and processing aspects.

Bakelite's many applications

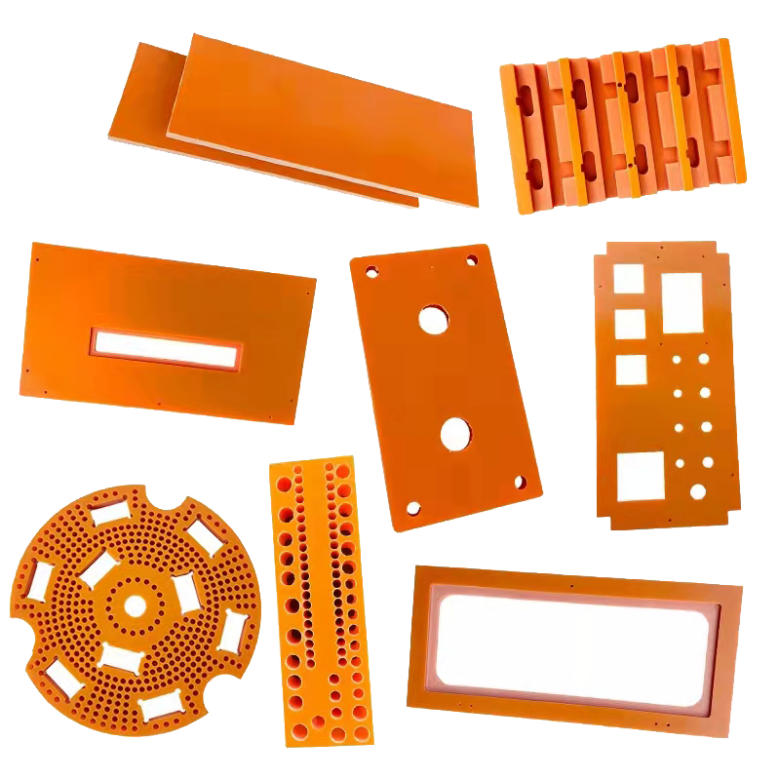

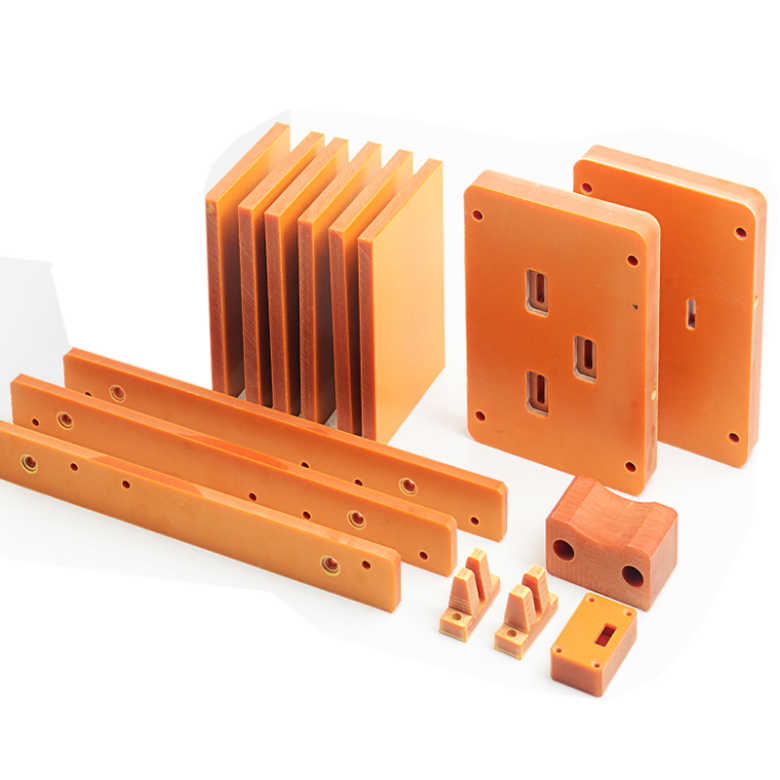

Bakelite processed products

As a material with excellent performance, bakelite has a wide range of applications. Through mechanical processing, bakelite can be made into various shapes of products, such as bakelite processed parts, these products in the electrical, mechanical and other fields play an important role.

Bakelite board processing products play an important role in electrical machinery and electrical equipment with high mechanical performance requirements, and are often used as insulating structural parts, and can work stably in transformer oil, showing good mechanical strength. In addition, they are also widely used in many fields such as pads for drilling in the PCB industry, distribution boxes, jig boards, mold clamps, high and low voltage wiring boxes, packaging machines, and combs. Whether for motors, mechanical molds, PCBs, ICT fixtures, or molding machines, drilling machines, table grinding pads, bakelite processed products can meet a variety of needs. For imported bakelite, its application range is even wider, including PCB drilling, silicone rubber molds, fixtures, switchboards and electrical machinery parts. Customers can choose and purchase flexibly according to their actual needs.

The economic value of bakelite board

Exploring the applications and advantages of orange-red bakelite panels

Orange Red Bakelite Board, as a high-performance insulating material, plays a key role in several fields. Its excellent electrical performance, stable physical properties and good processing performance make it ideal for use in the manufacture of electric motors and electrical equipment. Whether it is used as an insulating structural component or working stably in transformer oil, orange-red Bakelite board can demonstrate its excellent mechanical strength and meet the needs of various complex environments. In addition, it is widely used in many fields such as pads for drilling in the PCB industry, distribution boxes, jig boards, etc., bringing significant economic benefits to customers.

Black Bakelite

Bakelite products have become an ideal alternative to many plastic products due to its low raw material price and excellent product characteristics. Compared with ABS and other materials, the raw material cost of bakelite is only about half. Although bakelite products need to be heated in the process of molding, resulting in a slightly longer processing time than ordinary plastic, and higher requirements for mold steel, but these factors have not weakened its position as a cost-effective alternative. For the pursuit of cost-effective large customers, in the procurement of sheet, bakelite board is undoubtedly an option worth considering.

Related Keywords

Related Keywords