High Temperature Resistance Bakelite Hylam Sheets

-

$5.901-99 Kilogram

-

$5.80100-999 Kilogram

-

$5.70≥1000 Kilogram

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Guangzhou, HongKong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50000 pcs per day |

| Supply Ability: | Enough |

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Certificate: | SGS RoHS Reach ISO9001 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Guangzhou,HongKong |

HONY®Orange Bakelite Phenolic Paper Laminated Sheet for PCB Jigs and Fixtures Bakelite sheet,also called phenolic paper laminated sheet.It is formed by heat pressing after the paper pulp dip into phenolic resin. It is the most common laminated sheet.It is also the most widely used industrial laminated sheet

What is Bakelite?

A.Bakelite :

* Bakelite(sometimes spelledBaekelite) is a combination of phenol, formaldehyde, and wood flour. The mixture is put under pressure, and after curing, a hard plastic material forms.

* Bakelite 3021:also called Paper-based phenolic laminated sheet,is consists of impregnated paper dipped in resin by baking and hot pressing.3021 is the most commonly sen laminates,as well as having the widest applications and largest usage.

* Bakelite 3025:also called Phenolic cotton cloth laminated sheet is consists of cotton cloth dipped in phenolic resin by baking hot pressing.3025 is manufactured by modified phenolic resin as binder and pure cotton fabric as reinforcement.They have exceptionally good heat resistance and will not creep under high temperature conditions.

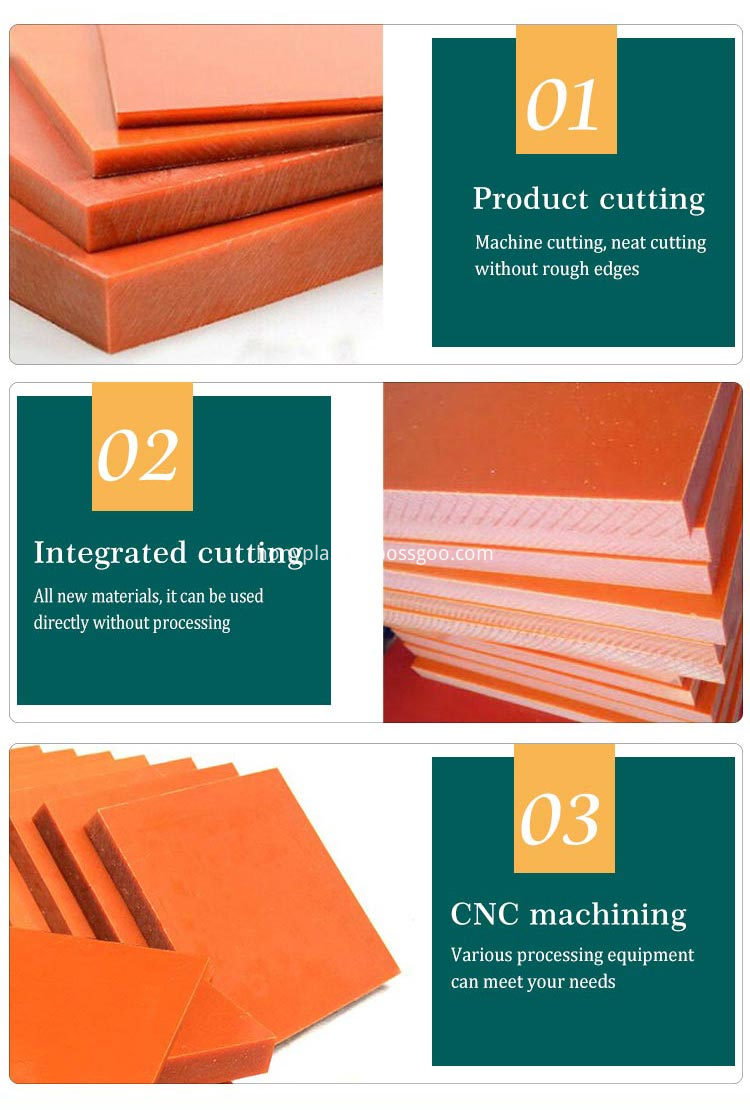

B.Bakelite Sheet / rod features

* Excellent physical,mechanical and dielectric properties

* Withstand all kinds of machining

* Surface smooth, no bubbles, hemp eye and impurities

* Edges cutting tidiness, Surface without delamination and crack

C.Bakelite Sheet / rod applications

* In insulating structural parts

* Electric equipments

* Aeronautical industries

Product features: good mechanical strength, anti-static, intermediate electrical insulation, non-absorbent, non-conductive, high temperature resistance

Scope of application: mechanical transmission parts, precision mechanical parts, water-resistant parts, electronic and electrical parts, etc.

Application field: The product is suitable for insulating structural parts in motors and electrical equipment with high mechanical performance requirements, and can be used in transformer oil. With good mechanical strength, it is suitable for drilling backing plates, power distribution boxes, jig boards, mold splints, high and low voltage wiring boxes, packaging machines, combs, etc. in PCB industry. Suitable for motors, mechanical molds, PCBs, ICT fixtures. Forming machine, drilling machine, table polishing pad

HONY®Bakelite Properties Data Sheet

Name

Bakelite sheet

Grade

A grade

Density(g/cm3)

1.45

Water absorption 24hrs(%)

<1.6

Max. service temperature -Short term(°C)

300

Max. service temperature - Long term(°C)

140

Heat deflection temperature-HDT/A(°C)

150

Coefficient of linear thermal expansion(10-4*K-1)

10

Thermal Conductivity W/(m.K)

/

Flammability

UL94 HB

Tensile Strength at yield(MPa)

≥100

Tensile Strength at break(MPa)

/

Hardness Shore-D

98

Impact Strength(kJ/m2)

67

Bending Strength(MPa)

≥120

Elongation at break (%)

≥0.03

Warping degree(‰)

<0.3

Volume resistivity Ohm (Ω) * cm

10^10~10^12

Surface resistivity Ohm (Ω)

10^10~10^12

Breakdown voltage-CW(kV)

10

Arc resistance(sec)

/

We are confidents to provide with CUSTOMIZED high quality Epoxy glass fiber Fr4/g10 products by our professional manufacturing team, manufacturing lines and experienced CNC router operators who have been engaged in this industry for more than 10 years.

Main Production

Machine

Package

Related Keywords