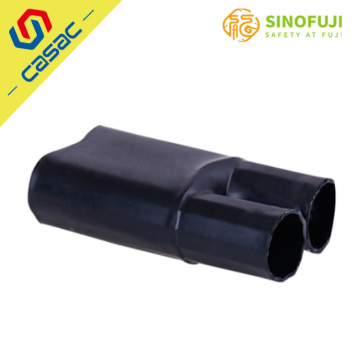

SINOFUJI Bare Wire Protective Overhead Power Line Cover

Your message must be between 20 to 2000 characters

Contact NowBare Wire Protective Overhead Power Line Cover

Description

SINOFUJI Bare Wire Protective Overhead Power Line Cover, ease of installation. Use silicone rubber material, anti-aging, corrosion resistance, with good resistance to corona resistance, high temperature performance, especially suitable for the protection of the bare wire. Anti-Aging Corrosion Resistance Silicone Rubber Overhead Power Line Cover widely used in substation protection works and railway catenary system, a significant effect in the cross-lines. Anti-Aging Corrosion Resistance Silicone Rubber Overhead Power Line Cover Pictures below:

Installation Instructions

1. Clean the inside of the product with cleaning cloth and alcohol fluids until the inside is

clean without dust;

2. Connect the pointed plastic mouth to the body of RTV silicone rubber adhesive bottle. See illustration 1 above.

3. Smear RTV silicone rubber adhesive all over the concave channel of the product

uniformly as showed in illustration

4. Uniformly smear the two flat fringes of the concave channel with RTV silicone

rubber adhesive as the illustration

5,Connect the bulging part of the product on one side into the concave channel of the

other side and squeeze the connecting part from one end to the other as illustration 4 indicates

| Voltage(KV) | ≤10KV | ≤35KV | ≤110KV | ≤220KV |

| Thickness | 2.0±0.3mm | 2.6±0.4mm | 4.0±0.5mm | 6.0±1.0mm |

Technical Performance

| Serial No. | Properties | Unit | Standard Data | Test Results | Test Methods |

| 1 | Electrical Strength Test | kV/mm | ≥20 | 22 | GB/T 1408.1-2006 |

| 2 | Volume Resistivity | Ω·cm | ≥1×1014 | 2×1014 | GB/T 1410-2006 |

| 3 | Dielectric Constant | 2~3 | 2.3 | GB/T 1409-2006 | |

| 4 | Shore Hardness | A | 70±5 | 71 | GB/T 531 |

| 5 | Mechanical Properties | GB/T 528 | |||

| 5.1 | Before heat ageing | ||||

| Tensile Strength | MPa | ≥4.0 | 5.5 | ||

| Elongation at break | % | ≥200 | 243 | ||

| 5.2 | After Heat ageing(180ºC, 7d) | % | ±30 | 13 | |

|

Tensile Strength Change Elongation Change |

% | ±30 | -22 | ||

| 6 | Low Temperature Elongation(-15ºC, 2h) | % | ≥20 | 190 | GB/T 2951.4-1997 |

| 7 | Low Temperature Flexibility(-50ºC, 4h) | - | No cracks | No cracks | UL224-2004 |

| 8 | High Temperature Crack Resistance(155ºC, 2h) | - | No cracks | No cracks | GB/T2951.6-1997 |

cal Per

Structure

Dimensions

|

LJ Stranded Wire Cross-sectional Area(Nominal) |

O.D. Of LJ Stranded Wire(mm) |

Silicone Rubber Sleeving Covers Models(mm) |

|

50 |

9.00 |

12 |

|

70 |

10.80 |

12 |

|

95 |

12.48 |

17 |

|

120 |

14.25 |

17 |

|

150 |

15.75 |

20 |

|

185 |

17.50 |

20 |

|

210 |

18.75 |

24.2 |

|

240 |

20.00 |

24.2 |

|

300 |

22.40 |

24.2 |

|

400 |

25.90 |

30 |

|

500 |

29.12 |

32 |

|

630 |

32.67 |

35 |

|

800 |

36.90 |

39.8 |

|

LGJ Stranded Wire& LGJF Stranded Wire Cross-sectional Area(Nominal) |

O.D. Of LJ Stranded Wire(mm) |

Silicone Rubber Sleeving Covers Models(mm) |

|

35 |

-- |

12 |

|

50 |

-- |

15.6 |

|

70/10 |

11.4 |

17 |

|

70/40 |

13.6 |

17 |

|

95/15 |

13.61 |

17 |

|

95/20 |

13.87 |

17 |

|

95/55 |

16 |

17 |

|

120/7 |

14.5 |

20 |

|

120/20 |

15.07 |

20 |

|

120/25 |

15.74 |

20 |

|

120/70 |

18 |

20 |

|

150/8 |

16 |

20 |

|

150/20 |

16.67 |

20 |

|

150/25 |

17.1 |

20 |

|

150/35 |

17.5 |

20 |

|

LGJJ-120 |

15.5 |

20 |

|

LGJJ-150 |

17.5 |

20 |

|

LGJQ-150 |

16 |

20 |

|

185/10 |

18 |

24.2 |

|

185/25 |

18.9 |

24.2 |

|

185/30 |

18.88 |

24.2 |

|

185/45 |

19.6 |

24.2 |

|

210/10 |

19 |

24.2 |

|

210/25 |

19.98 |

24.2 |

|

210/35 |

20.38 |

24.2 |

|

210/50 |

20.86 |

24.2 |

|

240/30 |

21.6 |

24.2 |

|

240/40 |

21.66 |

24.2 |

|

240/55 |

22.4 |

24.2 |

|

LGJJ-185 |

19.6 |

24.2 |

|

LGJJ-240 |

22.4 |

24.2 |

|

LGJQ-185 |

18.4 |

24.2 |

|

LGJQ-240 |

21.6 |

24.2 |

|

400/20 |

26.91 |

32 |

|

400/25 |

26.64 |

32 |

|

400/35 |

26.82 |

32 |

|

400/50 |

27.63 |

32 |

|

400/65 |

28 |

32 |

|

400/95 |

29.14 |

32 |

|

500/35 |

30 |

32 |

|

500/45 |

30 |

32 |

|

500/65 |

30.96 |

32 |

|

800/55 |

38.4 |

39.8 |

|

800/70 |

38.58 |

39.8 |

|

800/100 |

38.58 |

39.8 |

Related Keywords