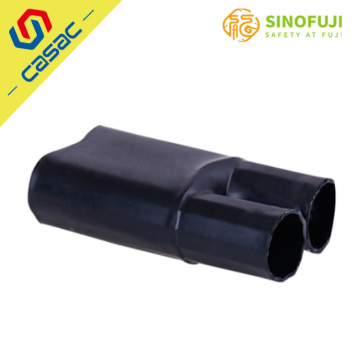

Cable End Cold Shrink Caps for Sealing Insulation

Your message must be between 20 to 2000 characters

Contact NowCable End Cold Shrink Caps for Sealing Insulation

Description

Waterproof Sealing EPDM Cold Shrink End Caps,environmentally seal and mechanically protect exposed cable ends using no tools,mastics or tapes. They are close-ended, tubular EPDM rubber sleeves that are factory expanded and loaded onto a removable core. When positioned over the end of a cable, or other cylindrical object, the core is removed to provide a reliable seal that protects your cable ends from environmental damage. Waterproof Sealing EPDM Cold Shrink End Caps easily installed and cleanly removable. Whether in transit from the manufacturer, stored in the cable yard, or in process in a trench, your cable ends are protected from exposure to moisture, contamination and corrosion.. Four different end caps are available to accommodate a wide range of sizes.

² Accommodates size ranges from 11.6mm – 84.0mm.

² Good abrasion resistance.

² Seals tight, retains resiliency and pressure even after prolonged years of ageing and exposure.

² Water-resistant.

² No mastic or tape required.

² No torches or heat required.

² Resists fungus.

² Resists acids and alkalis.

² Resists ozone.

² Easily removed.

² No training required for installation.

Removal

Once installed, the End Caps can be easily removed from the cable. Simply lift the edge of the end cap; slice the material with a utility knife and the end cap comes off cleanly, leaving no adhesive residue or grease.

Maintenance

The End Caps are stable under normal storage conditions. Normal storage and stock

Rotation is recommended.

Properties

|

Physical Property(Test Method) |

Typical Value US units (metrical) |

|

Color |

Black |

|

300%Modulus(ASTM D 214-87) |

480 psi(3.3 MPa) |

|

Ultimate Tensile(ASTM D 412-87) |

1400 psi(9.6 MPa) |

|

Ultimate eLONGATION(ASTM D 412-87) |

750% |

|

Die C Tear (ASTM G-21) |

150 pli (26.3KN/m) |

|

Moisture Absorption-7days in H2O |

Wt.Gain 1.8% |

Related Keywords