PSA Oxygen Plant for Pulp Making

-

$10000.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air, Others

- Port:

- FOB Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Transportation: | Ocean,Land,Air,Others |

| Port: | FOB Shanghai |

PSA Oxygen Plant for Pulp Bleaching and Papermaking Industry

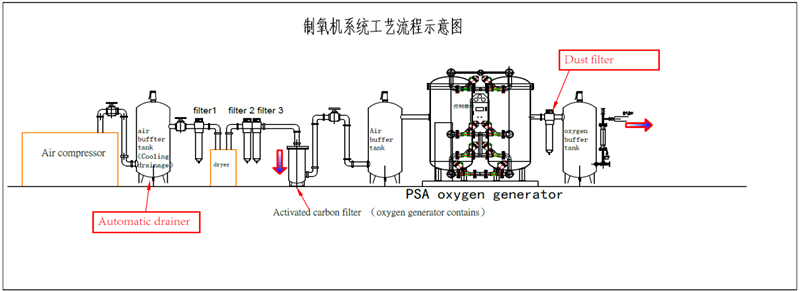

PSA Oxygen Plant for Pulp bleaching and papermaking:

Using the oxygen-rich bleaching to replace the chlorine bleaching, many pulp processes can be intensified or optimised.

PSA O2 plant is used as one On-site N2/O2 Production SystemOxygen is usually supplied in bottled nitrogen, liquid nitrogen, PSA or membrane field production, it not only allows professional users to become gas producers, plug and play, producing on demand.

Moreover, compared to buying cylinder/liquid N2/O2, except for the equipment input, it only consumes air and electricity, more cost-efficient, convenient and safe. Please contact us if necessary.

Kunpeng has Air Separation Plants, Liquid Oxygen / Nitrogen Plant, PSA Oxygen/Nitrogen Generator, Medical (gas) Oxygen Plant, VPSA Oxygen / Nitrogen Generator, and so on. If you need, please don't hesitate to contact us.

Meanwhile we also provide OEM/ODM service, you just need to tell us the gas use industry, capacity, purity, outlet pressure and equipent brand, we can design and produce for you.

Oxygen production: 5 ~ 1000Nm3/h

Purity of oxygen: 93%±2%

Oxygen pressure: ≤3 bar(Adjustable)

Dew point: ≤-40ºC(Adjustable)

| Model | O2 Cpacity(Nm3/h) | Purity |

| HO2005 | 5 | 93%±2% |

| HO2010 | 10 | 93%±2% |

| HO2020 | 20 | 93%±2% |

| HO2040 | 40 | 93%±2% |

| HO2050 | 50 | 93%±2% |

| HO2080 | 80 | 93%±2% |

| HO2100 | 100 | 93%±2% |

| HO2150 | 150 | 93%±2% |

| HO2200 | 200 | 93%±2% |

⊙ The equipment has the advantages of low energy consumption, low cost, strong adaptability, fast gas production and easy adjustment of purity.

⊙ Perfect process design and best use effect;

⊙ Modular design is designed to save land area.

⊙ The operation is simple, the performance is stable, the automation level is high, and it can be realized without operation.

⊙ Reasonable internal components, uniform air distribution, and reduce the high speed impact of airflow;

⊙ Special carbon molecular sieve protection measures to extend the life of carbon molecular sieve.

⊙ The key components of famous brands are the effective guarantee of equipment quality.

⊙ The automatic emptying device of national patent technology guarantees the nitrogen quality of finished products.

⊙ It has many functions of fault diagnosis, alarm and automatic processing.

⊙ Optional touch screen display, dew point detection, energy saving control, DCS communication and so on.

Send Inquiry Please bring the following description, we have more models to recommend to you ~! Thank you~!

| Technical Information | Your Kind Requirement |

| Capacity |

_________Nm³/h |

| Purity | _________% |

| Outlet Pressure | _________Mpa or Bar |

| Power |

________V/HZ |

Related Keywords