Oxygen Gas Generator Machine Hotsale Overseas

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | T/T,Others |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

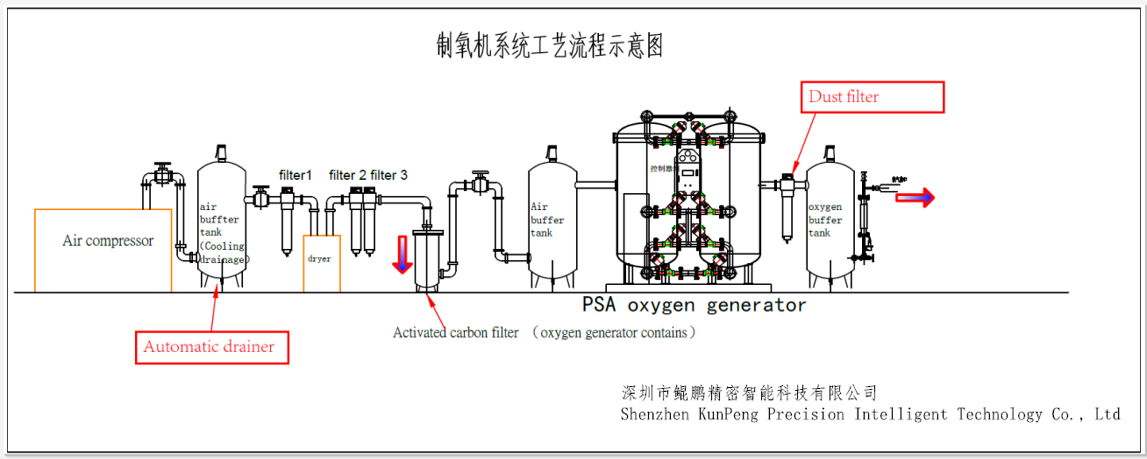

PSA oxygen generator who has 2-vessels filled with zeolite molecular sieves. Clean compressed air at 30º C temperature. is passed through 1-vessel and oxygen/nitrogen comes out as product gas. The other vessel is depressurized to atmospheric pressure and purged with little quantity of oxygen/nitrogen coming out from other vessel. This regenerates zeolite molecular sieves for use in next cycle. Thus 2-vessels keep cycling alternately in oxygen/nitrogen production and regeneration making oxygen/nitrogen gas available continuously.

PSA Oxygen Generator In Stock

2. Lower Space Requirement: The design and Instrumentation makes the plant size very compact, assembly on skids, prefabricated and supplied from factory.

3. Fast Start-up: Start-up time is about 30 minutes to get desired Oxygen purity. So these units can be switched ON & OFF as per Oxygen demand changes.

4. High Reliability: It's very reliable for continuous and steady operation with constant Oxygen/Nitrogen purity. Plant availability time is better than 90% always.

5. The professional snowstorm combined filling technology makes the molecular sieve packed more uniformly and densely, ensuring that the molecular sieve does not produce a fluidized state during the adsorption process, and there is no need to regularly supplement the expensive molecular sieve.

6. Low investment and energy consumption and simple operation and maintenance.

Related Keywords