Mini Oxygen Generator Gas Making Machine

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | strong |

| Payment Type: | T/T |

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai |

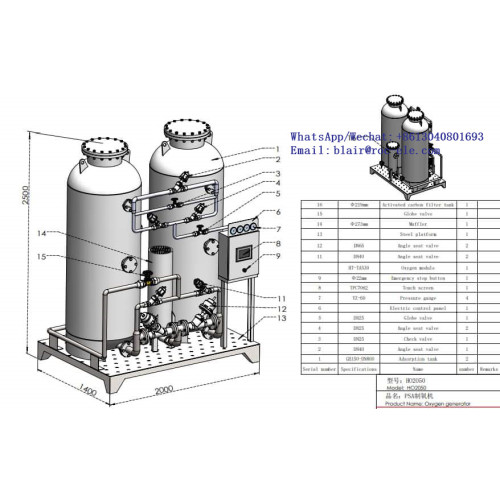

Mini Oxygen Generator Gas Making Machine

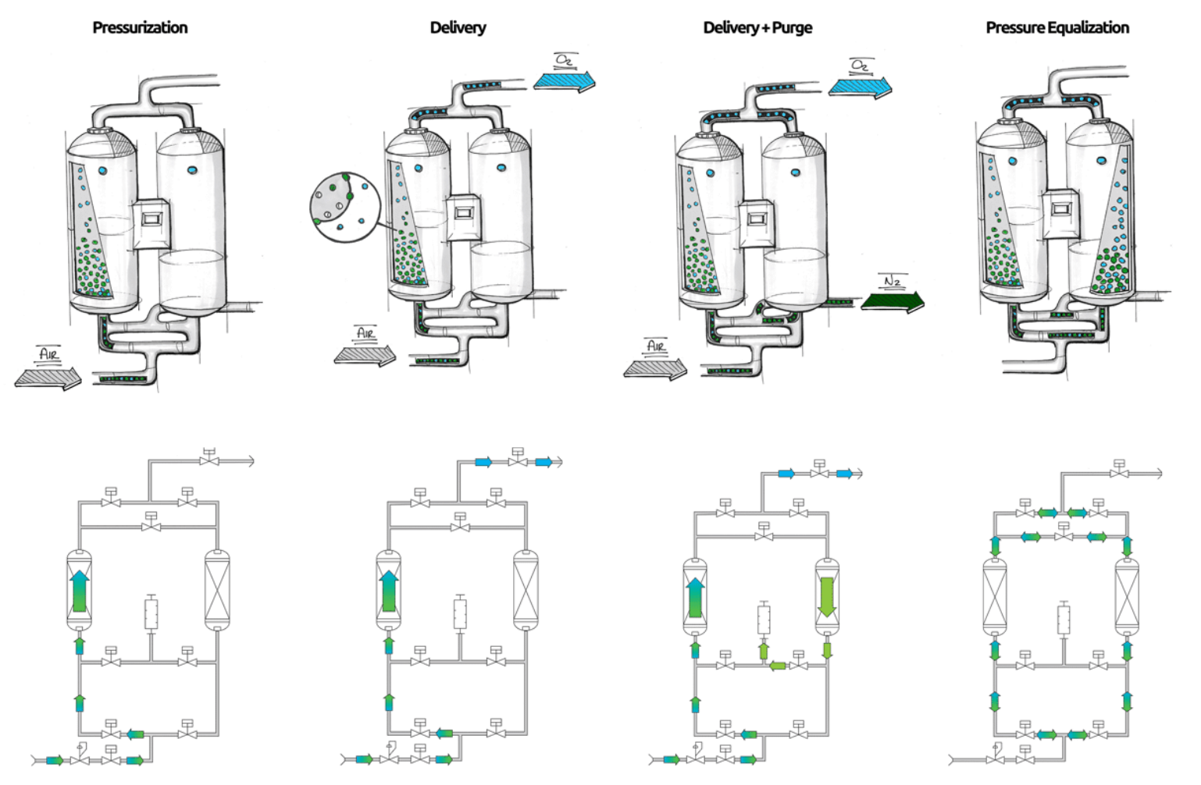

Molecular sieve oxygen generator is an advanced gas separation technology that directly extracts oxygen from the air. It is ready to use, fresh and natural. The maximum oxygen pressure is 0.2~0.3MPa, and there is no danger of high pressure and explosion. The PSA oxygen generator is based on the principle of pressure swing adsorption, using high-quality zeolite as the adsorbent, extracting oxygen from the air under a certain pressure, and performing pressure adsorption and decompression in the adsorber after the purified and dry compressed air Desorption. Due to the aerodynamic effect, the diffusion rate of nitrogen in the micropores of zeolite molecular sieve is much faster than that of oxygen. Nitrogen is preferentially adsorbed by zeolite molecular sieve, and oxygen is enriched in the gas phase to form finished oxygen.

Technical Features

3. Perfect oxygen device process design process, evenly distributed airflow, reducing the impact of high-speed airflow. Reasonable internal components for reduced energy consumption and investment costs

Related Keywords