200Nm3/h 99.999% Nitrogen Generator for Mini-led Industry

-

$10000.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | strong |

| Payment Type: | T/T |

| Incoterm: | FOB,EXW,CIF |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

N2 Generators for SMT Soldering

In the SMT electronic assembly industry, the use of Nitrogen Generation Plant can effectively inhibit the oxidation of solder, avoid bridging, and reduce soldering defects.The main purpose of adding nitrogen (N2) to the SMT reflow oven during PCBA processing is to reduce the oxidation of the soldering surface and improve the wettability of the soldering. Because nitrogen is an inert gas, it is not easy to form compounds with metals. Avoid oxygen in the air and metal contact to produce oxidation reaction.

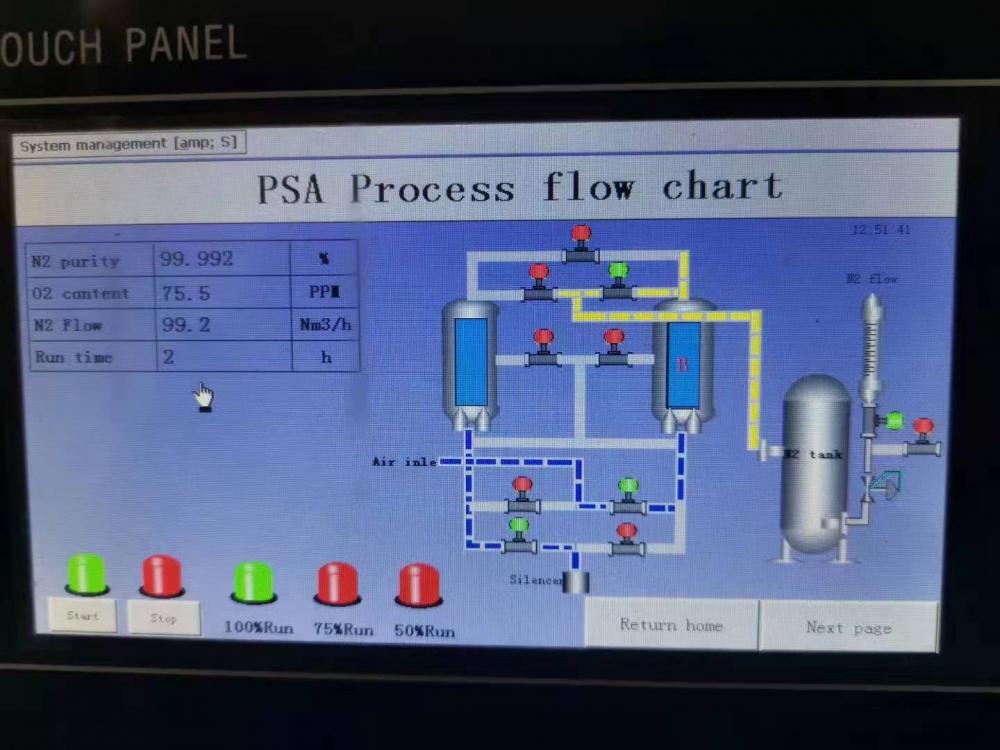

The PSA nitrogen generator mainly uses carbon molecular sieve as the adsorbent and compressed air as the main raw material. Utilizing the different adsorption rates of oxygen and nitrogen, carbon molecular sieves preferentially adsorb oxygen, while most of nitrogen is enriched in the non-adsorption phase, realizing the separation of oxygen and nitrogen. , to get the gasoline we need. Utilizing the principle and process of pressure swing adsorption, double adsorption towers are used in parallel to alternately adsorb, one tower works, and the other tower regenerates to continuously generate nitrogen. Qualified product gas with a purity of 99.99% -99.999% can be obtained at one time.

Our Kunpeng team can provide buyers with the services of qualified English engineers at the user's site, conduct on-site start-up, commissioning, installation supervision, training paid services, and send English engineers to the user's website. welcome to contact any Gas Production Equipment.

Related Keywords