Liquid Oxygen Generating Machine Equipment

- Transportation:

- Ocean, Land, Air, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | CFR,FOB,CIF,EXW |

| Transportation: | Ocean,Land,Air,Express |

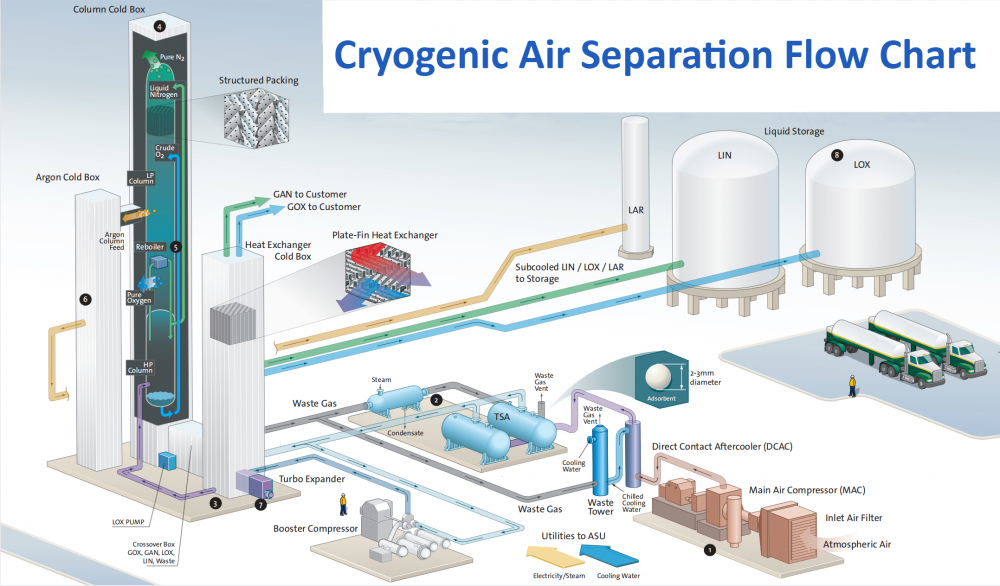

Principle of cryogenic air separation plant: The principle of cryogenic air separation is to use air as a raw material, compress it, purify it, heat compress it, and then liquefy the air. The product of air liquefaction is mainly a mixture of oxygen and nitrogen, and then use liquid oxygen and liquid nitrogen. The difference in boiling point is the process of rectification to finally obtain oxygen and nitrogen.Air separation is a complete set of equipment that uses certain methods to deep freeze the air, and then uses the difference in the boiling point of each gas to gradually separate oxygen, nitrogen and some rare gases. Among them, the important purification and rectification equipment in the cryogenic air separation oxygen plant are molecular sieves and air separation towers.

Common failure analysis and maintenance measures of cryogenic molecular sieve:

In the asu plant process, the cryogenic air separation tower is one of the most important equipment, which mainly includes the main heat exchanger, liquefier, rectification tower, condensing evaporator and so on. Nowadays, molecular sieve purification systems are generally used for air purification. Once it fails, it will affect the stability of the air separation tower. Therefore, we need to analyze the molecular sieve equipment failures in the cryogenic air separation oxygen purification system. So that it can be repaired in time in case of failure.

At present, the cryogenic method-cryogenic air separation oxygen production process is gradually perfected. In the cryogenic air separation process, the air separation tower and molecular sieve are one of the main equipment for preparing oxygen, nitrogen and other rare gases. Welcome to contact us for more Gas Production Equipment details.

Related Keywords