Top quality water cooled chiller trane

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 25 Days

- Transportation:

- Ocean, Land

- Port:

- Shenzhen, Yantian, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 20000set/month |

| Supply Ability: | 20000set/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO9001, CE |

| HS Code: | 8418699090 |

| Transportation: | Ocean,Land |

| Port: | Shenzhen,Yantian,Hongkong |

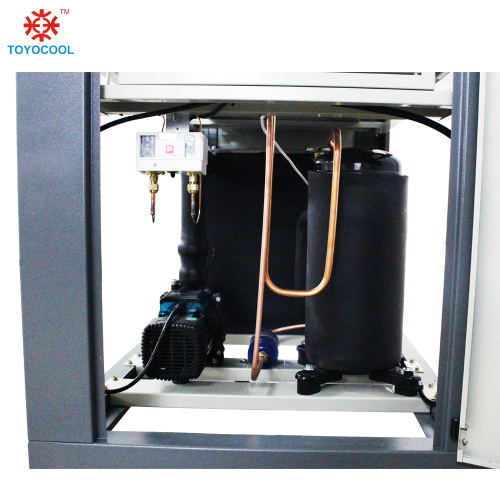

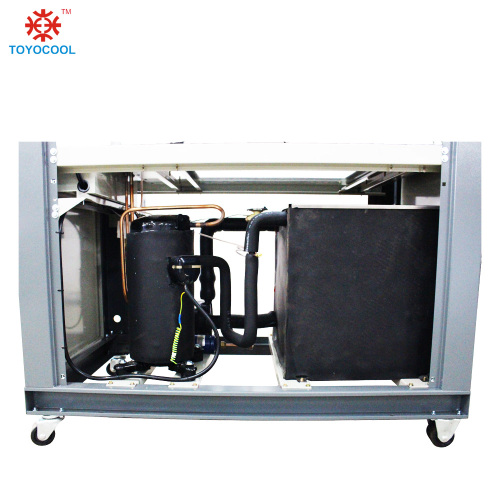

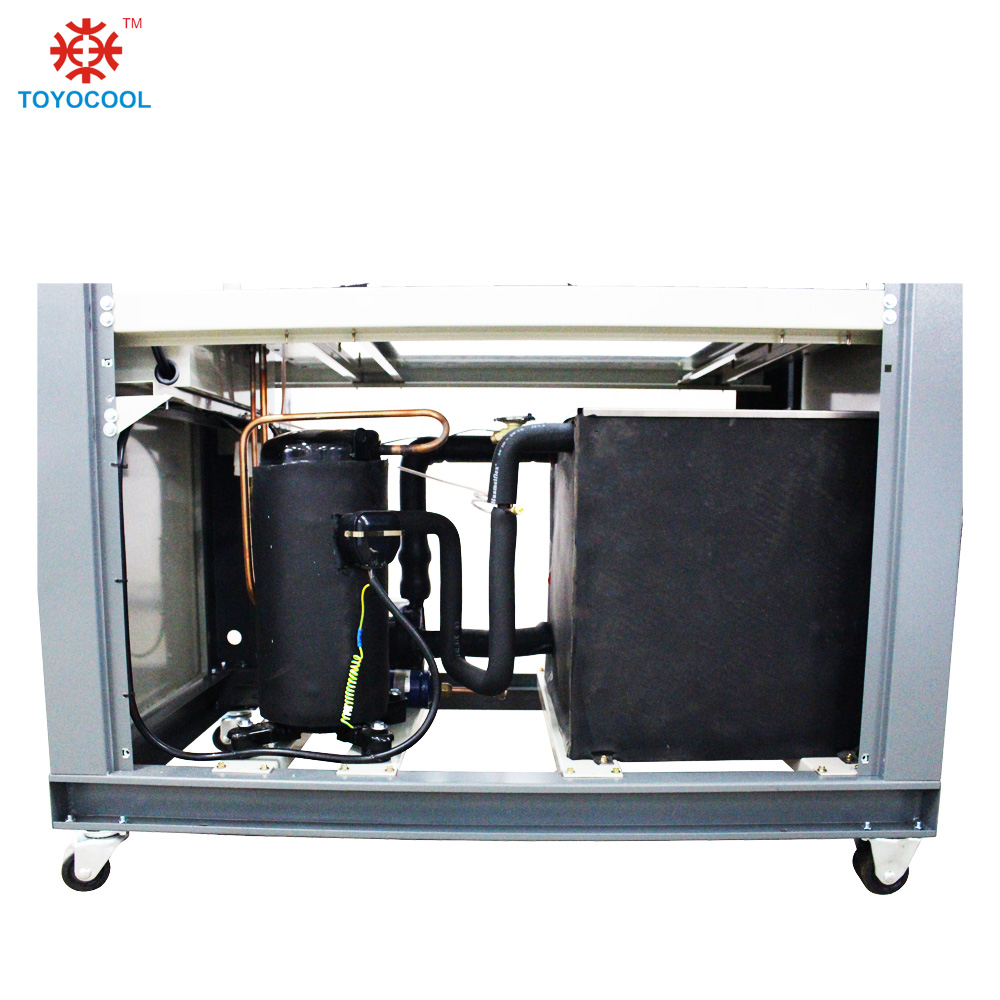

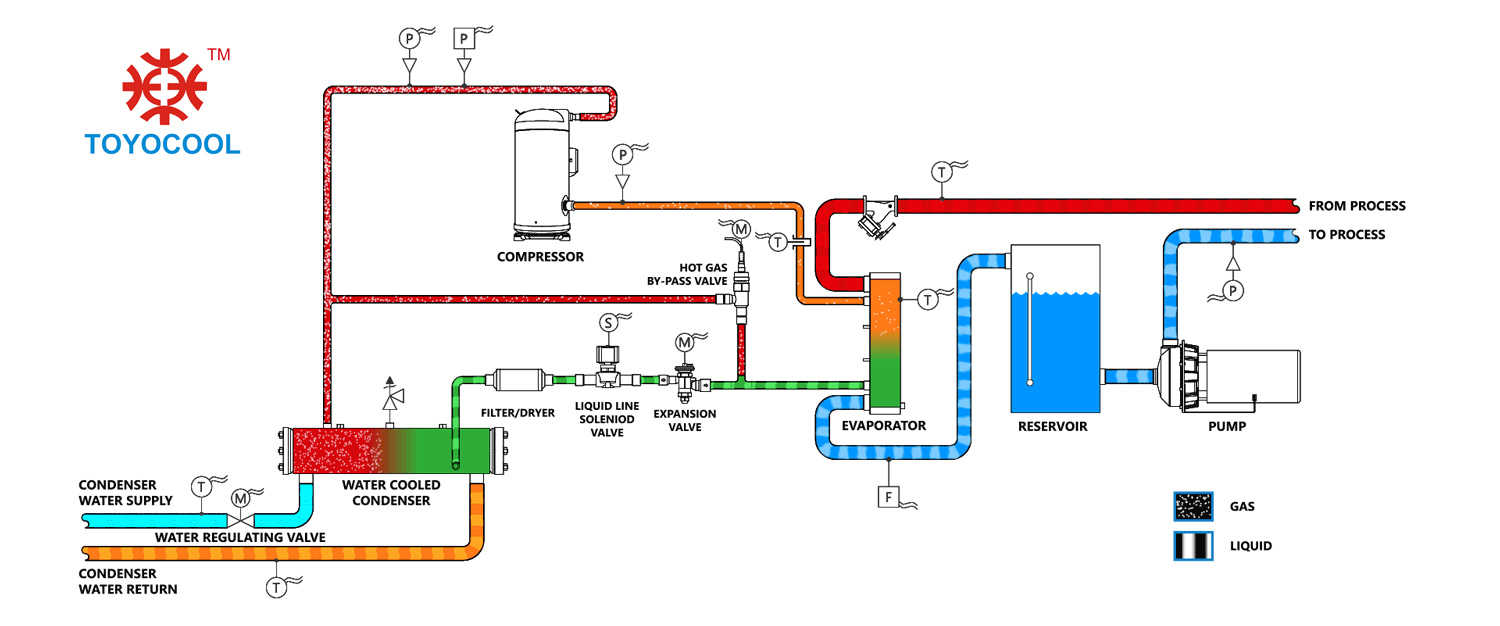

Water-cooled chiller,Water Cooling Chiller Machine,Box-type Water Cooling Chilling Equipment,water cooled chiller parts,water cooled chiller plant,water cooled chiller carrier,Water Cooled Chiller System: Water-cooled industrial chillers require circulating cooling water from the cooling water tower to lower the temperature. Therefore, to use water-cooled chillers, it is necessary to install cooling channel water towers, cooling water circulating water pumps, and pipes, which is cumbersome. Compared with air-cooled industrial chillers, it is easy to move.

Working of water cooled chiller:

1. The evaporation pressure is too low:

the reason:

(1) The amount of cold water is insufficient.

(2) Less cooling load.

(3) The orifice plate is faulty (only the evaporation pressure is low).

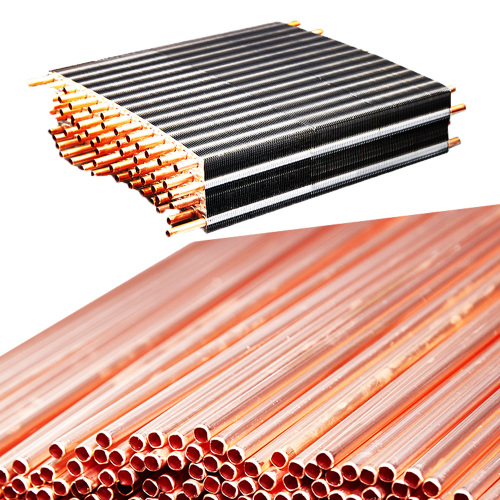

(4) The heat transfer tube of the evaporator deteriorates the heat transfer due to pollution such as scale (only the evaporation pressure is too low).

(5) The amount of refrigerant is insufficient (only the evaporation pressure is too low).

Treatment method:

(1) Check the cold water circuit to make the cold water volume reach the rated water volume.

(2) Check the setting temperature of the automatic start-stop device.

(3) Check whether the expansion throttle is smooth.

(4) Clean the heat transfer tube.

(5) Replenish the refrigerant to the required amount.

2. The condensation pressure is too high:

the reason:

(1) The amount of cold water is insufficient.

(2) The capacity of the cooling tower is reduced.

(3) The temperature of the cold water is too high and the cooling capacity is too large, which increases the load on the condenser.

(4) There is air.

(5) The heat transfer of the condenser tube is deteriorated due to pollution such as scale.

Approach:

(1) Check the cooling water circuit and adjust to the rated flow.

(2) Check the cooling tower.

(3) Check the expansion throttle, etc., so that the cold water temperature approaches the rated temperature as soon as possible.

(4) Perform the air extraction operation to remove air. If the air extraction device needs to be operated frequently, you must find out where the air leaks and eliminate it.

(5) Clean the tube.

3. The oil pressure difference is too low:

the reason:

(1) The oil filter is clogged.

(2) The opening of the oil pressure regulating valve (drain valve) is too large.

(3) The output of the oil pump is reduced.

(4) Bearing wear.

(5) The oil pressure gauge (or sensor) fails.

(6) Too much refrigerant is mixed in the lubricating oil (the oil pressure is too low due to oil bubbling at the start).

Approach:

(1) Replace the oil filter element.

(2) Close the small oil pressure regulating valve to increase the oil pressure to the rated oil pressure.

(3) Disassembly inspection.

(4) Replace the bearing after disassembly.

(5) Check the oil pressure gauge, recalibrate the pressure sensor, and replace if necessary.

(6) After the refrigerator stops, be sure to put the oil heater into operation to maintain the given oil temperature (confirm whether the oil heater is disconnected and whether the setting value of the oil heater temperature control is correct)

4. The oil temperature is too high:

the reason:

(1) The cooling capacity of the oil cooler is reduced.

(2) The supply amount of refrigerant for cooling the oil cooler is insufficient due to clogging of the refrigerant filter screen.

(3) Bearing wear.

Approach:

(1) Adjust the oil temperature regulating valve.

(2) Clean the refrigerant filter screen.

(3) Repair or replace the bearing after disassembly.

5. Overload of main motor:

the reason:

(1) Unbalanced power supply phase voltage.

(2) The voltage drop of the power line is large.

(3) The amount of cooling refrigerant supplied to the main motor is insufficient.

Approach:

(1) Take measures to balance the power supply phase voltage.

(2) Take measures to reduce the power line voltage drop.

(3) Check the refrigerant filter screen and clean the filter screen; open the refrigerant inlet valve.

water cooled industrial chiller, cooling water in industry,water cooling industrial systems,water cooling unit industrial

Related Keywords