Permanent Magnet Integral Drive Systems

- Payment Type:

- L/C, T/T, D/P, Paypal, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Air

- Port:

- Shenzhen, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1500 SETS/ YEAR |

| Supply Ability: | 2000 SETS/ YEAR |

| Payment Type: | L/C,T/T,D/P,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE,ISO 9001, ISO 14001, OHSAS 18001 |

| HS Code: | 8504409940 |

| Transportation: | Ocean,Air |

| Port: | Shenzhen,Qingdao,Shanghai |

The integral drive systems have no influence on the underground automation ring network, and are suitable for mines with underground mines and high-demand coal mines. YJVFT series mine explosion-proof integral drive systems is a highly integrated product of motor and variable frequency integrated machine. The integrated drive systems houston tx is applicable to belt conveyors, transfer machines, scraper conveyors, emulsion pumping stations and other coal mines that match the motor and the size of the connection. The integrated drive systems llc can realize the device's heavy-duty soft start, dynamic speed control and other functions.

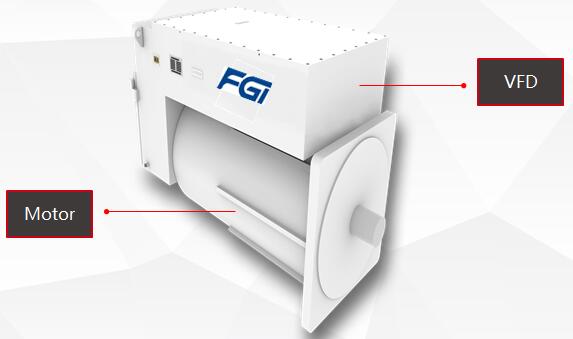

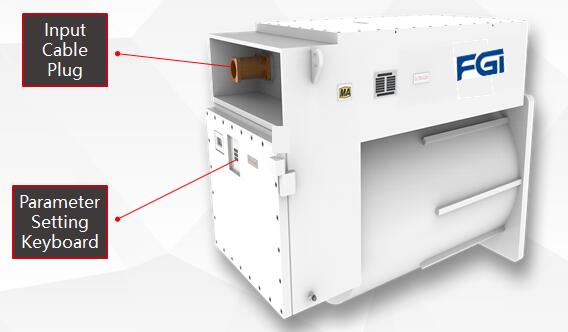

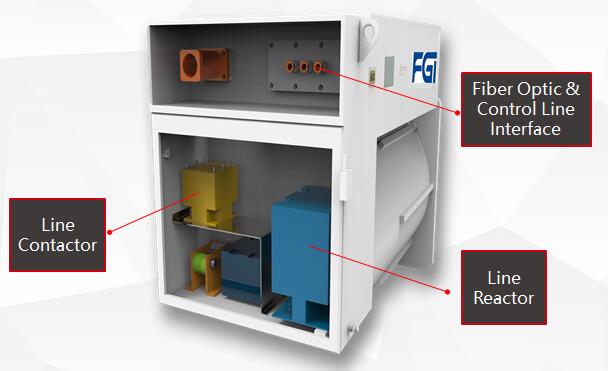

The Basic Structure of Explosion Proof Integral Drive Systems

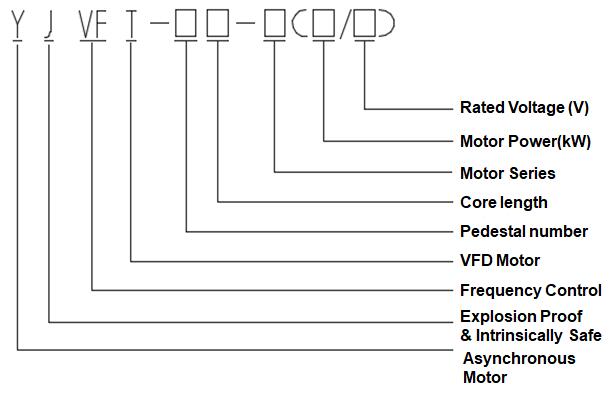

Product Model Description

Technical Advantages

- No need for long distance power supply filter and reactor

- Eliminate the influence of internal resistance of long-distance power supply cable on inverter control

- Eliminate the possibility of long-distance power supply cable grounding harmonic breakdown

- The motor is specially designed according to the frequency conversion performance and has a longer service life.

- No interference to other equipment, the system runs more stable

- No impact on the grid, low starting current

- Small size, no need for diverticulum placement or no equipment train

- Maintenance-free, improve production efficiency, reduce maintenance costs, and reduce maintenance time

Intelligent Permanent Magnet VFD Motor Controller Advantage

In addition to the excellent functions of the above-mentioned asynchronous all-in-one, there are the following advantages:

- Good power saving effect: power saving rate is increased by more than 30% compared with asynchronous machine

- Small starting current: Starting current is 15% smaller than asynchronous machine under the same starting torque

- Large starting torque: Under the same inverter capacity, the starting torque is increased by more than 15% compared with the asynchronous machine.

- High power factor: 25% higher power factor than asynchronous machine

- Low heat generation: Under the same load capacity, the temperature is lower than the asynchronous machine by more than 5 °C

- Small size: at the same power, the volume is reduced by more than 10% compared with the asynchronous machine

Application Advantages of Integral Drive Systems

- The VFD and the motor are integrated, the motor is specially designed according to the frequency conversion performance, and the frequency conversion is designed according to the professional design of the motor, so that both can reach the best working performance.

- Space saving, no need for special diverticulum or equipment train to place the VFD.

- The VFD output contains a large amount of harmonic components. When the VFD is far away from the motor, it will generate a high induced voltage on the motor side, which may damage the insulation of the motor.

- The coal mining face, the VFD can not be very close to the scraper motor. An output filter must be used.

- After using the VFD, the motor and the VFD are very close, no output filter is needed.

- In the case of long-distance power supply, the internal resistance of the cable from the VFD to the motor cannot be ignored. When the VFD adopts sensorless control, it is necessary to accurately measure the relevant parameters of the motor, the internal resistance of the long cable, and the influence on the accuracy of the VFD control is very big.

- After the VFD is used, the distance between the motor and the VFD is very close, which eliminates the influence of the internal resistance of the cable on the VFD control.

-The output of the VFD contains a large amount of harmonic components. In the case of long-distance power supply, the overall distributed capacitance of the cable is very large. The high-order harmonics resonate during charging and discharging to the ground, which has a great impact on the insulation of the cable. .

- After using the VFD integrated machine, the distance between the motor and the VFD is very close, eliminating the cable resonance effect

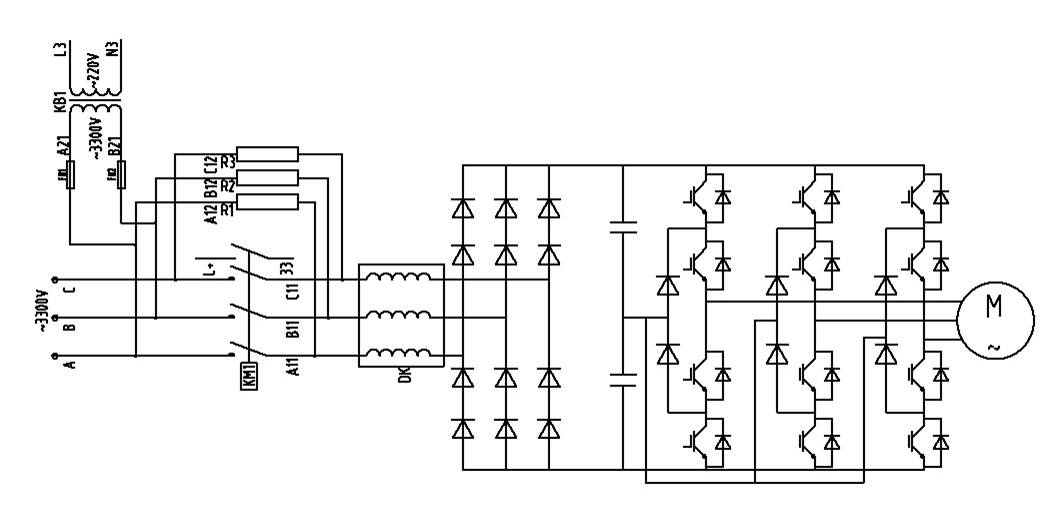

Schematic Diagram of Explosion Proof Integral Drive Systems

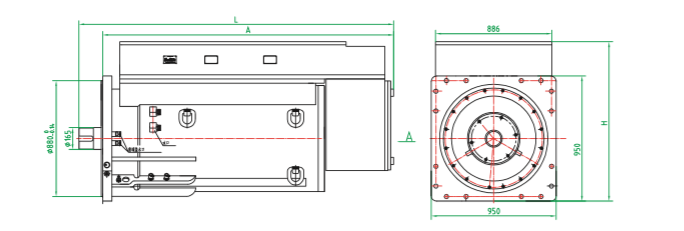

Performance Parameters

-Rated Input

Input Voltage: three phase 3.3kVac

Input Frequency: 50Hz

Input Current: It depends

Rated Power: 1600kW

Rated speed (r/min): 1490r/min

-Rated Output

Output Speed Range: 0~1490r/min

Frequency Conversion Output Frequency Range: 0~50Hz constant torque, 50~60Hz constant power

-Installation Environment

Installation Method: IMB5

Number of Poles: 4

Motor Thermal Classification: H level(180)

Work System: Continuous work system (S1)

Protection Level: IP56

Cooling Method: Water cooling (IC3W7)

Cooling Water Requirement: ≥2.7m3/h.≤25℃.≤3MPa

Intrinsically Safe Explosion Proof Parameter: Uo:12.0V Io:50mA, Uo:23.2VAC Io:226mA Co:1.0uF Lo:0.1mH

Working Conditions

The VFD motor shall be capable of rated operation under the following conditions:

- the altitude does not exceed 2000m;

- Ambient air temperature -10 ° C ~ +40 ° C (the coal mine does not exceed 40 ° C);

- The relative humidity of the air is not more than 98% (at +25 ° C, underground coal mine);

- Coal mine working environment containing the danger of methane and coal dust explosion;

Selection Guide

For more information, please download the attached.

Application

The explosion proof integral drive systems are suitable for belt conveyors, transfer machines, scraper conveyors, emulsion pumping stations and other equipment that match the size of the motor and the size of the connection. The VFD motor can realize the functions of heavy-duty soft start and dynamic speed control of the device.

Customer Visit

Our Service

OEM Service is available

After-sales responding within 24 hours

One to one pre-sales consulting services

We are factory with high-tech professional engineer teams

Technician could be assigned to go abroad to carry out site commissioning and technical training

Related Keywords