Energy Saving Amorphous Metal Core Transformers

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 SETS/ YEAR |

| Supply Ability: | 15000 SETS/ YEAR |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE,ISO 9001, ISO 14001, OHSAS 18001 |

| HS Code: | 85043190 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Qingdao,Shanghai |

The amorphous alloy material has a single piece thickness of only 0.03 mm, so its lamination factor can only reach 82% to 86%. The distribution transformers core is made of amorphous alloy material into a three-phase five-column structure, featuring low temperature rise and low loss. The no-load loss of the FGI SBH15 series Amorphous Metal Core Transformers is 30% of the S13 series oil immersed transformer. The high and low voltage coils are wound around, so that the iron core, metglas amorphous core, the low voltage coil and the high voltage coil are very tightly combined, and there is no set gap. As one of 2000 kva transformer manufacturers, the FGI transformer power has strong short circuit capability compared with similar electric transformers in the industry.

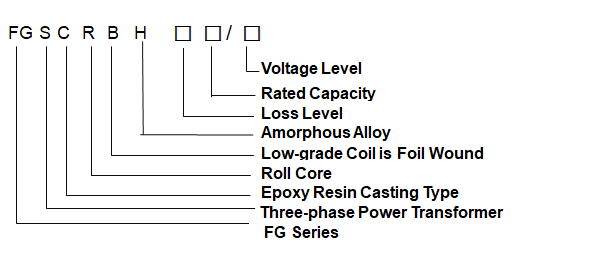

Product Model Description

Conditions of Use

- Type of device: Outdoor type

- Normal environmental conditions: Altitude does not exceed 1000m

- Special environmental conditions: Altitude does exceeds 1000m

- Ambient temperature:

Maximum temperature: +40℃

Minimum temperature: -25℃

Maximum daily average temperature: +30℃

Maximum annual average temperature: +20℃

- Power supply voltage waveform: The waveform of the power supply voltage is approximately sinusoidal

- Installation place: No corrosive gas, no obvious dirt environment

- Note: If the annual minimum temperature of the installation site is below -25 °C, use DB-45# transformer oil

Performance Features

1. Amorphous core transformers cores are made of amorphous alloy strip coils, no-load loss is about 75% lower than that of S11 series distribution transformers.

2. Copper foil coils are used for low voltage transformers, resulting in stronger ability to resist sudden short circuit.

3. Amorphous core distribution transformers winding connection adopts Dynll to reduce the influence of harmonic on power grid and improve the quality of power supply.

4. Amorphous alloy transformers boxes adopt a fully sealed structure to prolong service life and be free of maintenance.

5. Amorphous alloy distribution transformers adopt vacuum oil injection to completely remove air bubbles in coils and ensure the stability of insulation performance.

6. Each three distribution transformer is tested with full wave lightning impulse tests for peak voltage before delivery, conforming to the national standard, to ensure fully operation of three phase distribution

transformers.

.

Technical Parameters

Rated power: 50/60 (KVA)

Efficiency (η): 100~1000

Voltage ratio: 10000/400 (V)

Shape structure: vertical

Cooling method: air-cooled

Moisture proof method: potting type

Number of windings: three windings

Core structure: amorphous alloy

Cooling form: dry

Core shape: R type

Power phase number: three phase

Frequency characteristics: low frequency

Model: SCRBH15-200/10

Applications: Electricity

Selection Guide

| Rated Capacity (kVA) | Voltage Combination | Winding Connection Grade | No-load Loss (W) | load Loss (W) | Short Circuit Impedance (%) | No-load Current (A) | ||

| High Voltage (kV) | Tapping Range of High Voltage(%) | Low Voltage (kV) | ||||||

| 30 | 6 6.3 6.6 10 10.5 11 | ±2×2.5 | 0.4 | Dyn11 | 33 | 630 | 4.0 | 1.5 |

| 50 | 43 | 910 | 1.2 | |||||

| 63 | 50 | 1090 | 1.0 | |||||

| 80 | 60 | 1310 | 0.9 | |||||

| 100 | 75 | 1580 | 0.8 | |||||

| 125 | 85 | 1890 | 0.6 | |||||

| 160 | 100 | 2310 | 0.6 | |||||

| 200 | 120 | 2730 | 0.6 | |||||

| 250 | 140 | 3200 | 0.5 | |||||

| 315 | 170 | 3830 | 0.5 | |||||

| 400 | 200 | 4520 | 0.5 | |||||

| 500 | 240 | 5430 | 0.3 | |||||

| 630 | 320 | 6200 | 4.5 | 0.3 | ||||

| 800 | 380 | 7500 | 0.3 | |||||

| 1000 | 450 | 10300 | 0.2 | |||||

| 1250 | 530 | 12000 | 0.2 | |||||

| 1600 | 630 | 14500 | 0.2 | |||||

| 2000 | 750 | 18300 | 0.2 | |||||

| 2500 | 900 | 21200 | 0.6 | |||||

Storage Instructions

When the oil filled transformers are stored, the oil level of the fully sealed transformer should be kept 2~3cm below the cover, and the storage condition should be checked regularly. For the transformer to be transported by the oil conservator, the oil conservator must be installed to ensure a certain amount of oil pressure and oil, to meet the needs of its temperature change, and the seal of the electricity transformers must be protected during storage.

Factory Show

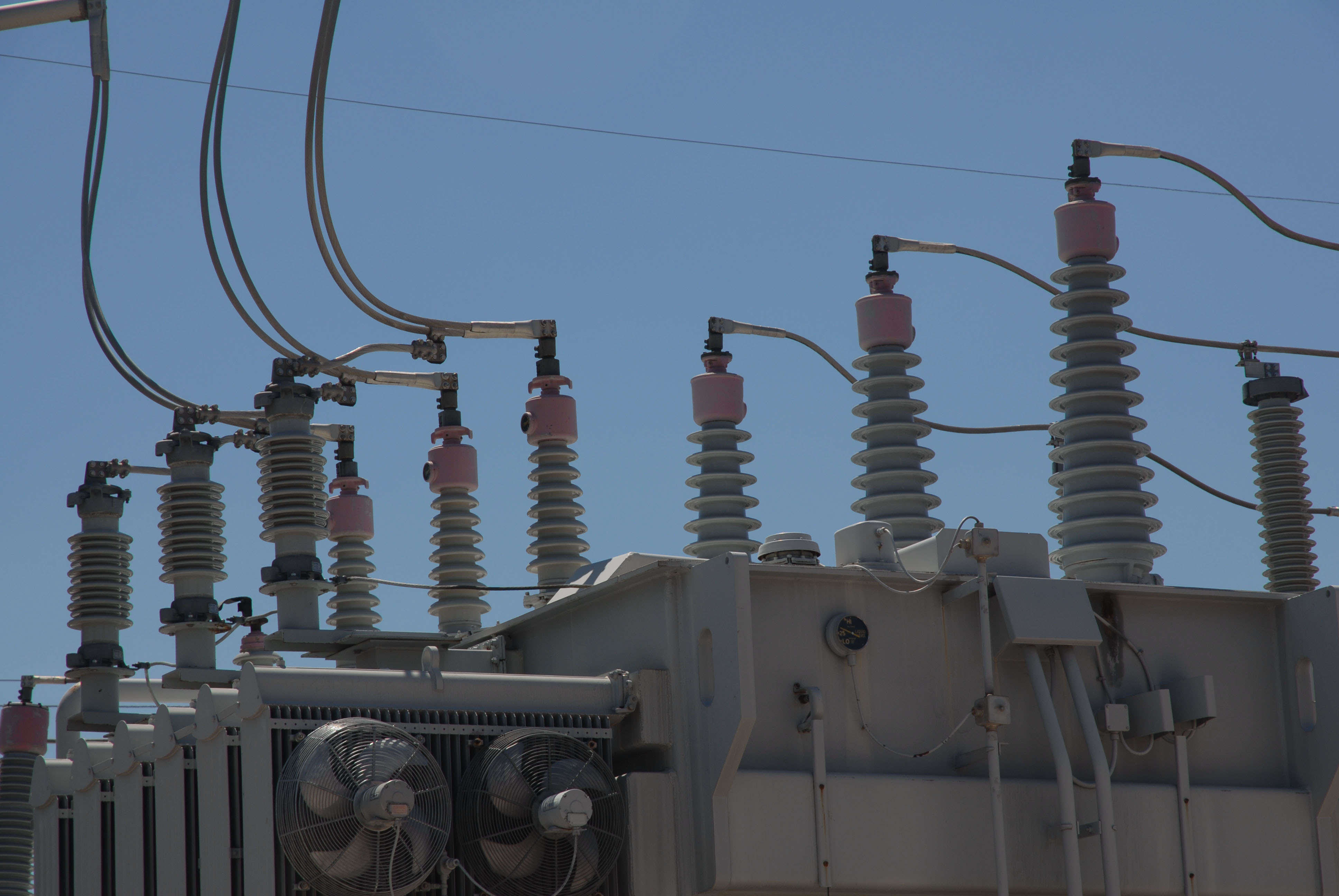

Application

In Service in diverse Industries, Electricity Boards, Nuclear / Thermal / Hydel Power Plants, Railway Traction, High-Rise Buildings, Hospitals, Subways, Underground Vaults, Tunnels, Schools, Steel Factories, Chemical Plants, etc. Where safety is of prime concern.

Quality Environmental Certification

Our Service

OEM Service is available

After-sales responding within 24 hours

One to one pre-sales consulting services

We are factory with high-tech professional engineer teams

Technician could be assigned to go abroad to carry out site commissioning and technical training

Related Keywords