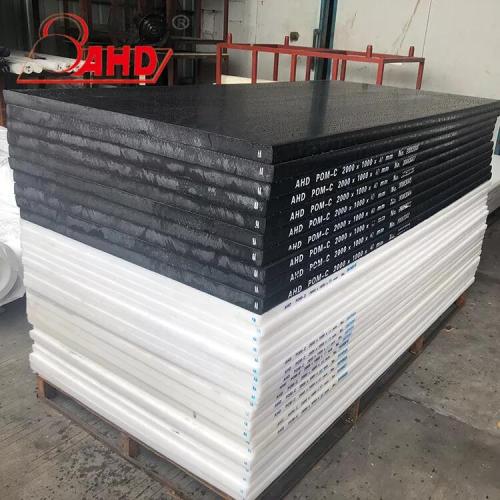

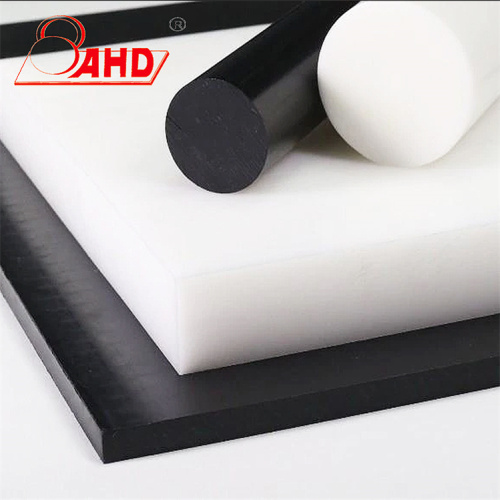

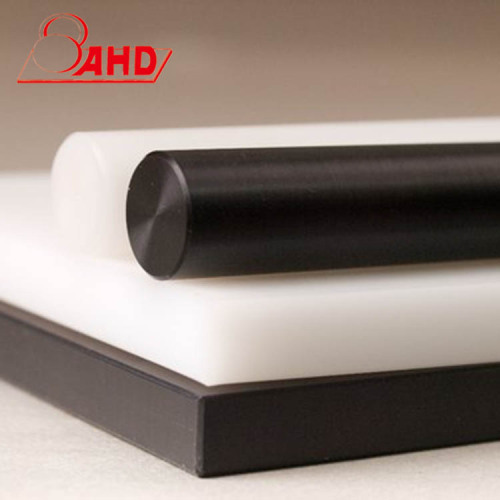

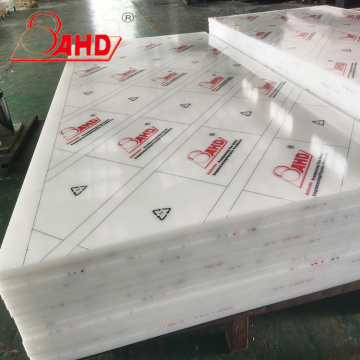

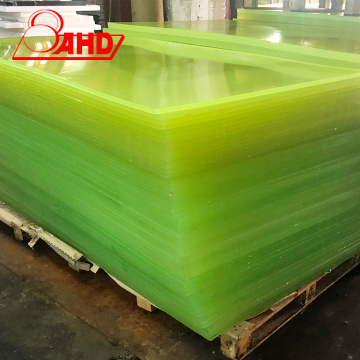

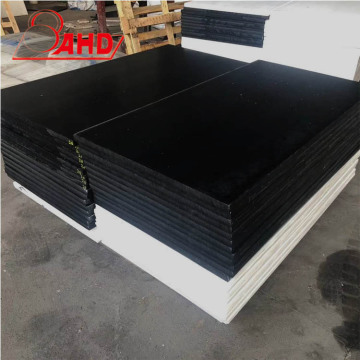

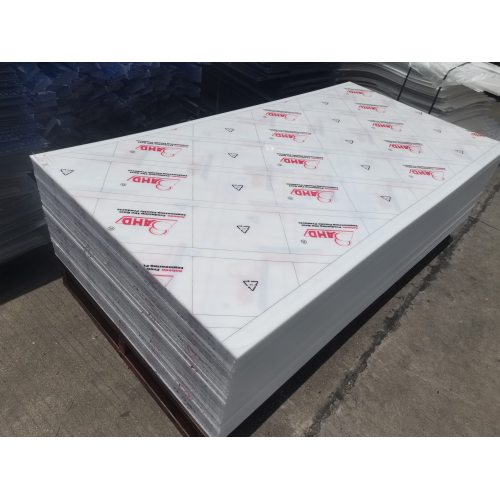

POM-C Plate Polyoxymethylene plastic Board Derlin White Black sheet

-

$2.60≥500 Kilogram

- Min. Order:

- 500 Kilogram

- Min. Order:

- 500 Kilogram

- Transportation:

- Ocean

- Port:

- SHENZHEN

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | CHINA |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Certificate: | ISO9001:2015 |

| Transportation: | Ocean |

| Port: | SHENZHEN |

Product Description

Product Description

POM Sheet, namely polyoxymethylene sheet, is a distinctive high-performance engineering plastic sheet that plays a crucial role in modern industry and numerous fields.

I. Material Properties

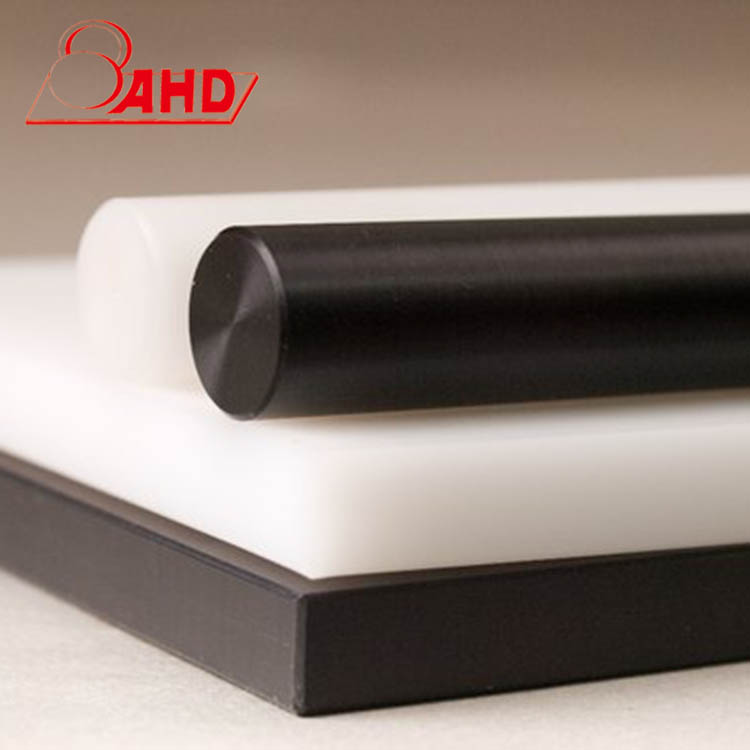

- High Mechanical Strength: It features outstanding rigidity and toughness, capable of withstanding high-intensity tensile, compressive, and bending loads. Even under complex stress conditions, it can maintain structural stability and is not easily damaged, providing a solid guarantee for precision mechanical structural components.

- Excellent Abrasion Resistance: Its surface is extremely smooth, with an extremely low coefficient of friction and self-lubricating properties. In high-speed and high-load sliding friction scenarios, the wear is minimal and the service life is extremely long, making it an ideal choice for frequently moving parts.

- Superior Fatigue Resistance: It can endure repeated stress cycle actions. In a long-term dynamic use environment, the material performance decays slowly, ensuring the continuous and reliable operation of components and reducing replacement frequency.

II. Physical Properties

- Good Dimensional Stability: It has a relatively high heat distortion temperature and a small coefficient of thermal expansion. Facing temperature fluctuations, the dimensional change is negligible, enabling it to precisely meet the requirements of various precision assembly needs and guarantee the long-term stable operation accuracy of equipment.

- Excellent Electrical Insulation: It can effectively block current conduction and is used as an insulating part in electronic and electrical equipment to prevent risks such as short circuits and leakage, ensuring the safety of the electrical system.

III. Processing Properties

- Easy Machining: The material is uniform, and the cutting resistance is small. Conventional machining methods such as turning, milling, and drilling can be used to precisely process components with complex shapes and fine dimensions, and the machined surface has a high finish.

- Thermoformable: Through thermoplastic molding processes, it can be molded into various curved and special-shaped structures to meet diverse design requirements, and the performance of the molded products is stable.

IV. Application Fields

- Automotive Industry: It is used to manufacture components such as window regulator gears, door handles, and interior trim clips. Relying on its abrasion resistance and toughness, it improves the operating convenience and interior quality of automobiles and reduces operating noise.

- Electronic and Electrical Appliances: It is widely applied in electrical switches, sockets, relay housings, printer gears, etc., to ensure the smooth and safe operation of electrical appliances while meeting the miniaturization and precision design trends.

- Precision Machinery: It performs outstandingly in transmission screws, guide rail sliders, bearing cages, etc. of automated equipment, ensuring high-precision, low-friction, and long-life mechanical motion.

Related Keywords

Related Keywords