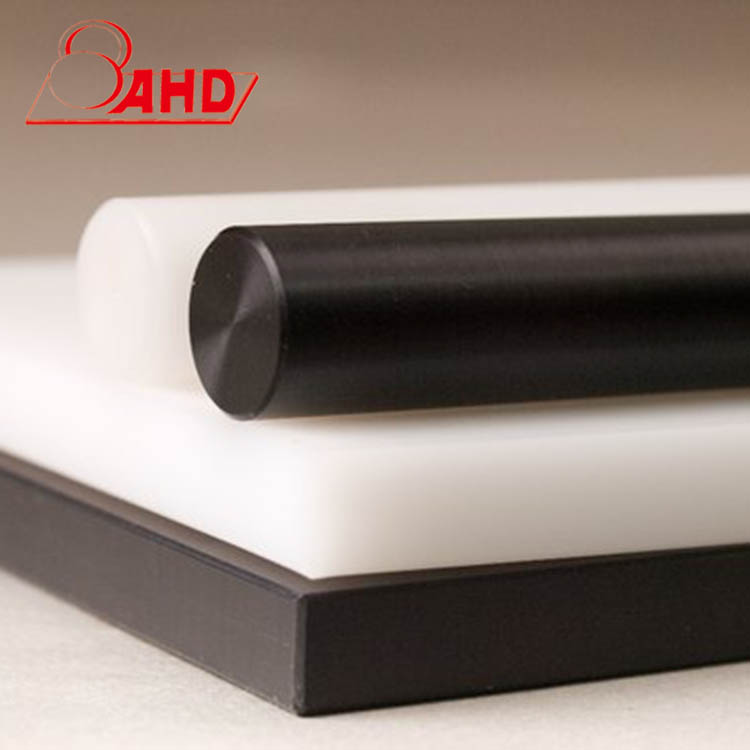

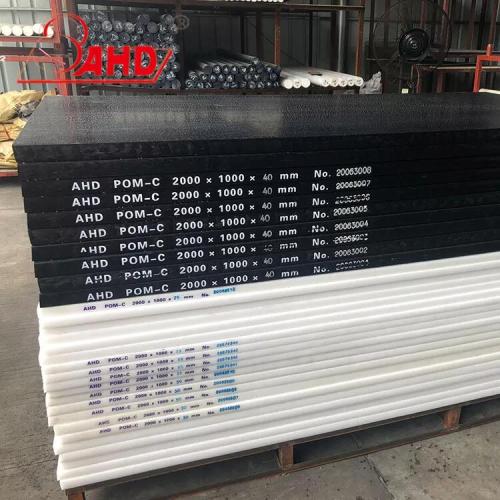

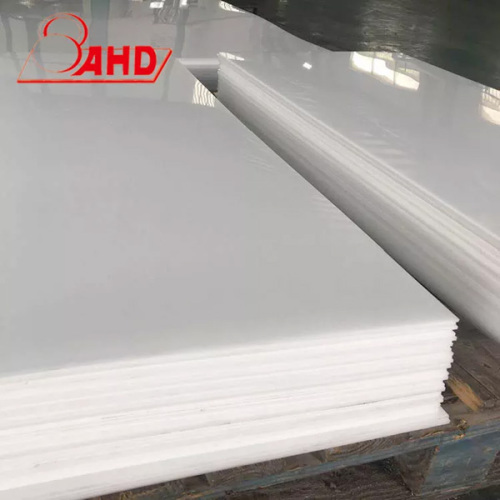

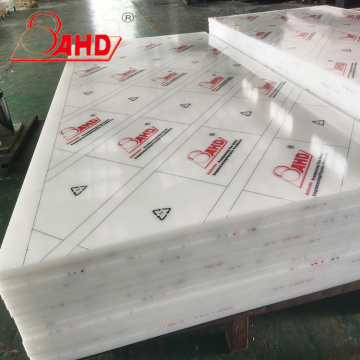

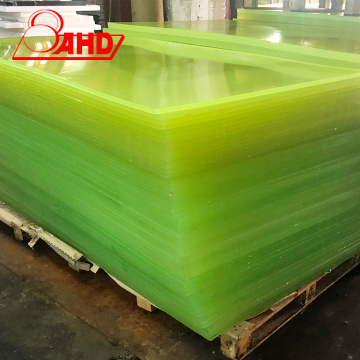

POM Sheet is produced through extrusion or injection molding processes using polyoxymethylene (POM) resin. The unique chemical structure of polyoxymethylene endows POM Sheet with outstanding characteristics such as high strength, high hardness, excellent wear resistance, good dimensional stability, and superior chemical resistance. It is widely used in numerous fields including electronics and electrical appliances, automotive, and is a key material in high-end manufacturing, facilitating the precise manufacturing and efficient operation of products.

- High Strength and High Hardness: It has high tensile and bending strength, capable of withstanding significant external forces without being easily deformed or fractured. With a high surface hardness, it can resist wear and scratches, and is used for gears and bushings in industrial machinery to ensure stable power transmission.

- Excellent Wear Resistance: It has a low coefficient of friction and is highly wear-resistant. During frictional contact, it can maintain dimensional accuracy and surface finish, reducing wear losses and downtime for maintenance. It is used for components that require frequent movement, such as window regulator gears in automobiles.

- High Fatigue Resistance: It maintains good performance under repeated alternating stress and is not prone to generating fatigue cracks. It is used for equipment that requires frequent start-stop and vibration, such as valve tappets in engines, ensuring safe and stable operation.

- Good Corrosion Resistance: It can tolerate a variety of chemical substances including organic acids and alkali solutions, and resist erosion under certain concentrations and temperatures, maintaining physical, mechanical, and appearance quality. It is used for lining chemical equipment and reagent containers in laboratories.

- Moderate Weather Resistance: It has stable performance indoors or under general outdoor sheltered conditions. Although its ability to resist ultraviolet rays and other outdoor elements is not as good as that of some specialized outdoor plastics, it can meet the requirements for indoor furniture connectors and outdoor electronic device housing support parts.

- Low Water Absorption: It hardly absorbs water and will not cause dimensional expansion, deformation, or performance degradation when in a humid environment or in contact with water. It is used for precision instruments and electronic device components to ensure accurate operation.

- Excellent Thermal Stability: It has good thermal stability within a certain temperature range, with a small coefficient of thermal expansion. When the temperature changes, the dimensional change is small. It can work for a long time from normal temperature to medium temperature and can withstand high-temperature impacts in a short time. It is used for heat-resistant parts in automobile engines and other applications.

- Easy to Cut: It can be processed using conventional metal cutting equipment and tools. Its cutting performance is similar to that of metals, with high precision and a smooth surface. The chips are easy to clean up, improving production efficiency and reducing costs. It is used for manufacturing precision mechanical parts.

- Partially Injection Moldable: Specific specifications can be injection molded with high efficiency, good product consistency, and easy control of precision. It is suitable for mass-producing small and precise parts, such as micro gears in electronic appliances, promoting the development of the electronics industry.

- Electronics and Electrical Appliances Industry

- Precision Transmission Components: Used to manufacture components such as the motor shaft of a computer hard disk drive, with high precision, wear resistance, and low noise, ensuring the accurate operation of equipment and the accuracy of data reading and writing, extending the service life and improving performance reliability.

- Connectors and Switches: Injection molded into electronic connectors and switches, with good insulation, strength, and precision, ensuring stable signal transmission and reliable connection, meeting the needs of product miniaturization and multifunctionality, and used in various electronic products.

- Automotive Industry

- Engine Components: Used for valve tappets and other components, with high strength, fatigue resistance, and thermal stability, ensuring the normal and efficient operation of the engine and improving the reliability and durability of the vehicle.

- Interior and Exterior Parts: Interior and exterior parts such as window regulator gears use POM Sheet, which is wear-resistant, chemically resistant, and has good appearance, meeting the requirements of aesthetics, comfort, and performance, and improving the quality and competitiveness of the vehicle.

- Aerospace Field

- Interior Decoration and Components: Interior components such as passenger cabin seat armrests use its lightweight and high-strength characteristics, meeting fire protection and other safety requirements, providing a comfortable environment for passengers. It is also used for the housings of aerospace electronic equipment to ensure the normal operation of the instruments.

- Model and Prototype Manufacturing: With good processing performance and simulation ability, it is used for the development of aerospace models and prototype prototypes, supporting research and development, accelerating progress and innovation.

- Industrial Machinery Manufacturing Industry

- Transmission System Components: Used as gears, sprockets, etc., with high strength, high hardness, and wear resistance, ensuring reliable power transmission, maintaining precision, and reducing costs. It is used in many fields such as machine tools, providing a material foundation for industrial manufacturing.

- Automation Equipment Components: Used to manufacture shafts, guide rail sliders, etc., with stable dimensions and fatigue resistance, ensuring high-precision positioning and reliable operation of automation equipment, promoting the transformation and upgrading of the manufacturing industry.

- Other Fields

- Medical Device Industry: Small transmission and joint connection parts use POM Sheet, which has good biocompatibility, low friction, and precision, is easy to clean and disinfect, and complies with hygiene standards, helping the development of the medical industry.

- Toy and Model Manufacturing Industry: Used for high-end toys and models, with good processability and sufficient strength, meeting the requirements of precision, strength, and appearance, and promoting the technological progress of the industry