Extruded Natural Color Ultempei1000 sheet PEI Plastic sheet

- Min. Order:

- 100 KG

- Min. Order:

- 100 KG

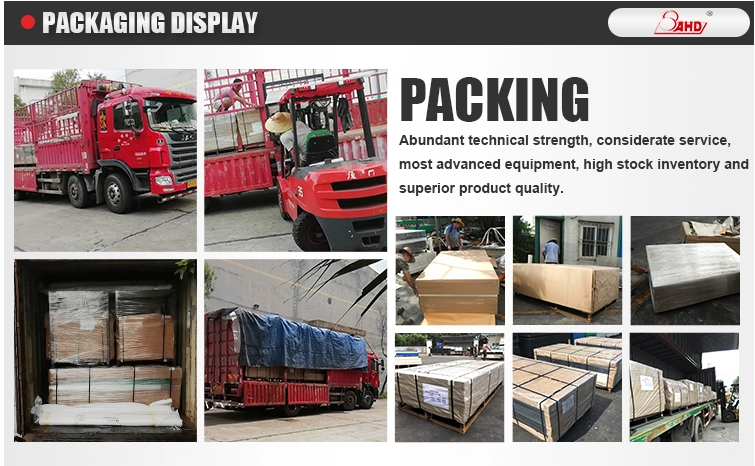

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shenzhen, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000 tonss per month |

| Supply Ability: | 3000 tons / month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Certificate: | SGS, ROSH, TUV |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou |

PEI sheet (full name polyetherimide sheet) is Polyetherimide, which is a non-crystalline plastic. It is an amorphous high-performance polymer. It is made of engineering plastics made of amorphous PEI (polyetherimide) and extruded at high temperature through an extruder. PEI board has excellent comprehensive balance performance, and is effectively used in electronics, automobiles, motors and aviation industries, and used as metal substitute materials for traditional products and cultural and daily necessities.

Application:

PEI board has excellent comprehensive balance performance, and is effectively used in electronics, automobiles, motors and aviation industries, and used as metal substitute materials for traditional products and cultural and daily necessities. Generally used in microtools/public catering industry, analytical instruments, medical equipment, telecommunications, molded interconnects (MTD), automotive lighting, aircraft interior parts, HVAC/fluid processing, etc.

PEI has excellent hydrolysis resistance, so it is used as handles, trays, clamps, prostheses, mirrors for medical lamps and dental appliances for medical surgical instruments.

Specification:

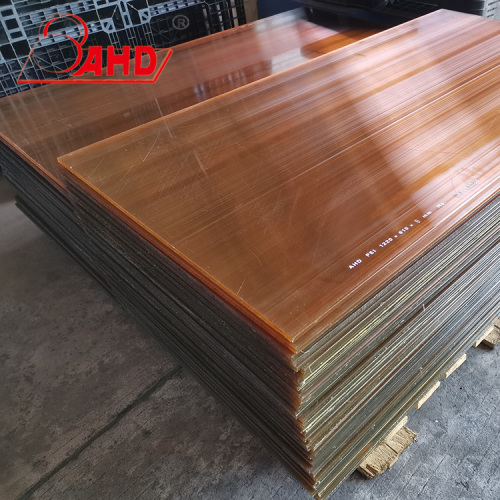

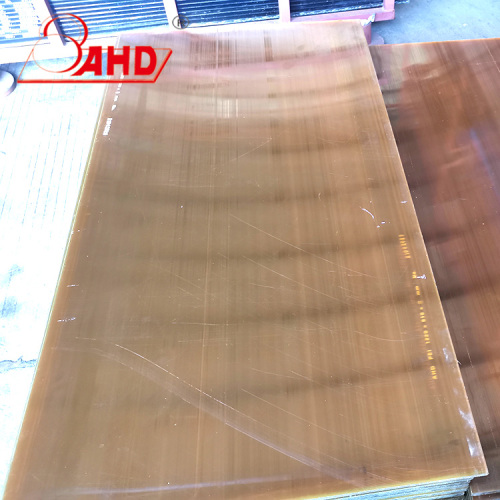

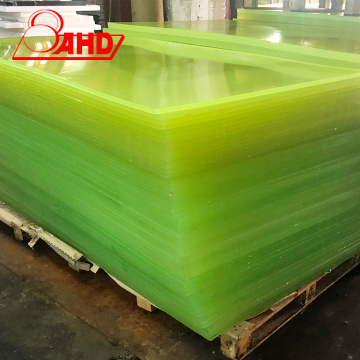

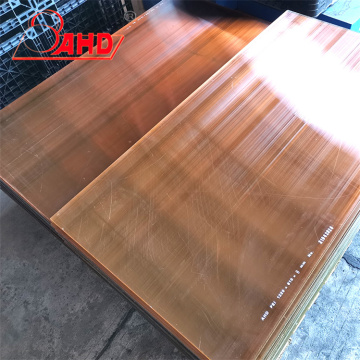

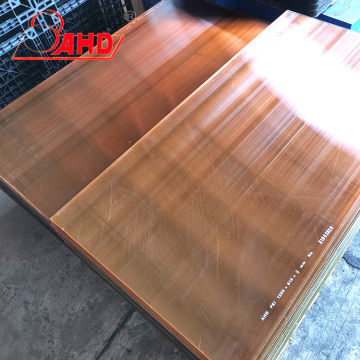

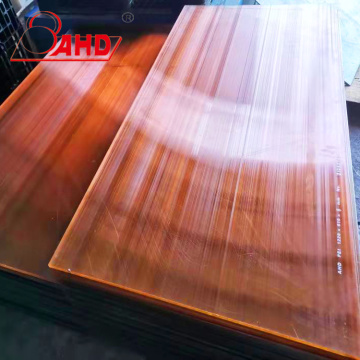

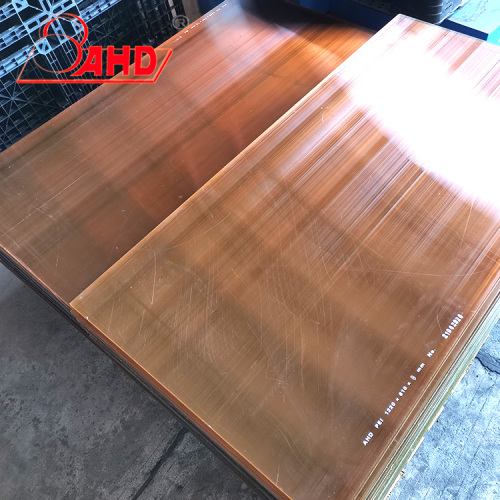

| Item name | PEI sheet |

| Size | 610x1220mm |

| Thickness | 6--50mm |

| Color | Amber |

| Density | 1.27 g/cm3 |

Physical Datesheet:

| Item | PEI sheet |

| Type | extruded |

| Thickness | 10---50mm |

| Size | 610x1220mm |

| Color | Amber |

| Proportion | 1.27g/cm³ |

| Heat resistance (continuous) | 170℃ |

| Heat resistance (short-term) | 200℃ |

| Melting point | _ |

| Glass transition temperature | 215℃ |

|

Linear thermal expansion coefficient (average 23~100℃) |

45×10-6m/(m.k) |

| Average 23--150℃ | 45×10-6m/(m.k) |

| Flammability(UI94) | V-0 |

| Tensile modulus of elasticity | 3400MPa |

| Dipping into water at 23℃ for 24h | 0.26 |

| Dipping into water at 23℃ | 1.35 |

| Bending tensile stress/ Tensile stress off shock | 105/- Mpa |

| Breaking tensile strain | >10% |

| Compressive stress of normal strain-1%/2% | 25/49 MPa |

| Pendulum gap impact test | 3.5 KJ/m2 |

| Friction coefficient | _ |

| Rockwell hardness | M114 |

| Dielectric strength | 30 kv/mm |

| Volume resistance | ≥10 18Ω×cm |

| Surface resistance | ≥10 17Ω×cm |

| Relative dielectric constant-100HZ/1MHz | 3/3 |

| Critical tracking index(CTI) | 175 |

| Bonding capacity | + |

| Food contact | + |

| Acid resistance | + |

| Alkali resistance | + |

| Carbonated water resistance | + |

| Aromatic compound resistance | + |

| Ketone resistance | - |

FAQ:

Q. Are you trade company or factory?

A: We are the factory of "PP SHEET, HDPE SHEET, POM SHEET, POM ROD, HDPE ROD, ABS SHEET, PA6 SHEET, PU SHEET, PU ROD manufacturer in China since 1994S and own more than 250 production lines

Q: What is your main goods?

A: Our products inlcude "PP, ABS, PU, PA6, PC, HDPE,PEI " sheet & rod

Q: Where is your factory?

A: We have 2 factories which produce different product, Shenzhen factory is located in Shajing Bao'an Dist, Donggunag factory is located in Hongmei Town, you are welcome to visit us to inspect by yourself

Q: Can i get free sample?

A: Sure, sample can be provided for quality checking and comparison if need. And we can ensure quality of mass production is same as sample

Q: What is the leading time?

A: The leading time is mainly depends on the order size, qty, color etc, if your have any inquiry, please send to us, we will check with production department to give an exact time! Normally will takes around 10--15 days for 20 tons sheets

Related Keywords