PC Polycarbonate Boards Sunshine Endurance Sheets

- Transportation:

- Ocean, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000 Ton/month |

| Supply Ability: | 3000 Ton/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | SGS/TUV/ISO:2015 |

| Transportation: | Ocean,Air |

| Port: | Shenzhen |

Solid polycarbonate sheets are almost non-fragile. It is made of polycarbonate and extruded. It has high temperature resistance and good lighting effects. Polycarbonate solid panels can be cold-bent, easy to manufacture and form, ideal for barrel domes, skylights, building roofs and glass. Transparent, translucent and opaque polycarbonate solid panels are also ideal for mechanical protection, sound insulation, vandal resistant and safety glass.

Pc Plastic Sheet Features:

1. Impact resistance: The impact force of the endurance board can reach up to 3kg/cm. The impact strength of the PC endurance board is 250-300 times that of ordinary glass, 20-30 times that of acrylic sheet, and twice that of tempered glass. There is no danger of breakage. There is no crack in the two meters below the 3kg hammer, and there is a reputation for "anti-dan glass" and "sound steel".

2, light transmission: excellent lighting, light transmittance of up to 75 ~ 90%, and its transparency can be comparable with glass. Exposure to sunlight does not produce yellowing, fogging, or poor light transmission. UV-coated panels do not produce yellowing under sunlight, and fogging, poor light transmission, after 10 years, the loss of light transmission is only 6%, the rate of PVC loss is as high as 15%-20%, and the fiberglass is 12 %-20%.

3, weather resistance: the surface has a co-extruded layer of UV protection, can prevent the fatigue of the resin caused by ultraviolet light from the sun. The surface coextruded layer has a chemical bond that absorbs ultraviolet light and is converted into visible light, which has a good stabilizing effect on plant photosynthesis. Outdoors can guarantee ten years without fading. Maintain the stability of various physical indicators in the range of -40 ° C to 120 ° C. The artificial climate aging test was 4000 hours, the yellowing degree was 2, and the light transmittance reduction value was only 0.6%.

4. Flame resistance: The endurance board itself does not self-ignite and has self-extinguishing properties. In line with the EU ROHS directive and strict UL safety regulations, UL94 fire rating reaches V0, V2, HB. PC board's own ignition point is 580 degrees Celsius, self-extinguishing from the fire, no toxic gas will be produced when burning, will not promote the spread of fire

5. Heat resistance and cold resistance: no deterioration in quality such as deformation occurs in the temperature range of -40 ° C to +120 ° C. The PC board does not undergo cold brittleness at -100 ° C, does not soften at 135 ° C, and has no significant change in mechanics and mechanical properties in a harsh environment.

6, light and hard: light weight, only half of the glass, 1/3 of the acrylic plate, good adaptability and safety, easy to handle, drill, cut off installation, not easy to break, simple construction and processing.

7. Strong plasticity: It can be installed in an arched, semi-circular top and window according to the design drawing. The minimum bending radius is 175 times the thickness of the plate, and it can also be bent.

8. Sound insulation: PC board has obvious sound insulation effect. It has better acoustic insulation than glass and sub-force board of the same thickness. Under the same thickness, the sound insulation of PC board is 3-4DB higher than that of glass. Internationally the material of choice for highway noise barriers.

9, energy-saving: summer cool, winter insulation, PC board has a lower thermal conductivity (K value) than ordinary glass and other plastics, insulation effect is 7%-25% higher than the equivalent glass, PC board insulation Up to 49%. Therefore, the heat loss is greatly reduced, and the building used for the heating equipment is an environmentally friendly material.

10. Anti-condensation: The outdoor temperature is 0 ° C, the indoor temperature is 23 ° C, and the indoor relative humidity is less than 80%, the inner surface of the material does not condense. Certification materials: UL certification, ROHS certification, etc.

Polycarbonate Sheets Application:

Polycarbonate Rod is widely used in machinery, electronics, automotive, construction, daily necessities, hand model and other fields, and it is rapidly expanding to many high-tech fields such as aviation, aerospace, electronic computers, optical discs, and optical fibers.

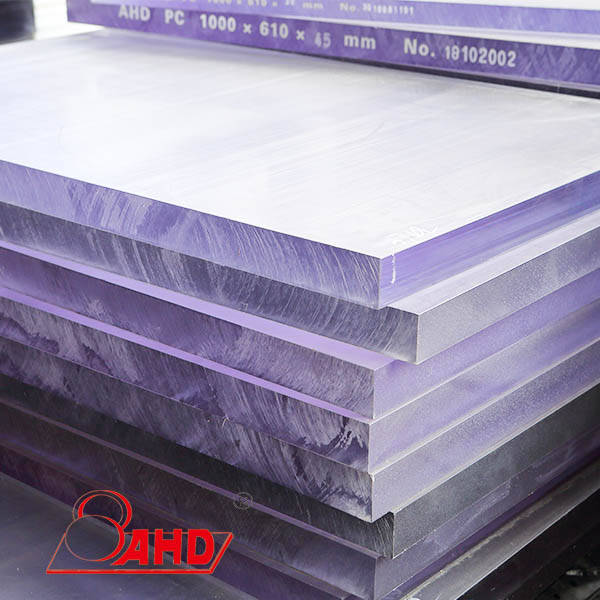

Specification

|

Item name |

PC ( Polycarbonate) sheet |

|

Type: |

extruded |

|

Size: |

1000*2000mm |

|

Thickness: |

15---200mm |

|

Density: |

1.2 g/cm³ |

|

Color: |

Translucent |

|

Brand name: |

AHD |

|

Material: |

100% virgin material |

|

Sample: |

FREE |

|

Acid resistance: |

YES |

|

Food Contact |

YES |

Physical Datasheet:

|

Item |

PC sheet |

|

Color: |

clear |

|

Proportion: |

1.2g/cm³ |

|

Heat resistance (continuous): |

125℃ |

|

Heat resistance (short-term): |

135℃ |

|

Glass transition temperature: |

150℃ |

|

Linear thermal expansion coefficient (average 23~100℃): |

65×10-6 m/(m.k) |

|

Average 23--150℃ |

65×10-6 m/(m.k) |

|

Flammability(UI94): |

HB |

|

Tensile modulus of elasticity: |

2400MPa |

|

Dipping into water at 23℃ for 24h |

13% |

|

Dipping into water at 23℃ |

0.35% |

|

Bending tensile stress/ Tensile stress off shock |

70/- Mpa |

|

Breaking tensile strain |

˃50% |

|

Compressive stress of normal strain-1%/2%: |

18/35 MPa |

|

Pendulum gap impact test |

9 KJ/m2 |

|

Friction coefficient: |

0.55 |

|

Rockwell hardness: |

M75 |

|

Dielectric strength: |

28 kv/mm |

|

Volume resistance: |

10 15Ω×cm |

|

Surface resistance: |

10 15Ω |

|

Relative dielectric constant-100HZ/1MHz: |

3/3 |

|

Critical tracking index(CTI) |

600 |

|

Bonding capacity: |

+ |

|

Food contact: |

+ |

|

Acid resistance: |

+ |

|

Alkali resistance |

- |

|

Carbonated water resistance: |

0 |

|

Aromatic compound resistance: |

- |

|

Ketone resistance: |

- |

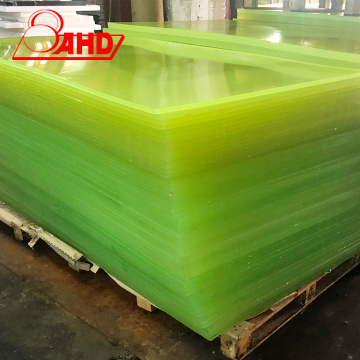

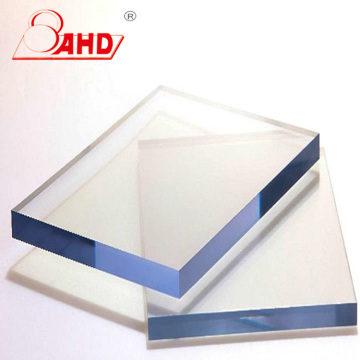

PC Sheet Photo:

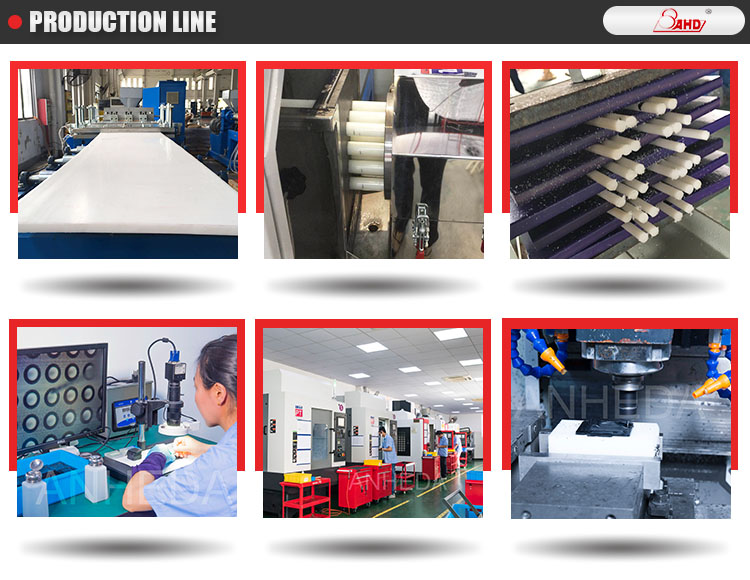

Company Profile:

Anheda Plastic Group(AHD) was established in 1994 in the first special economic zone in Shenzhen, China. As the earliest manufacturer of engineering plastic semi-finished products, the group was founded with the mission of providing customers with the most competitive products. The Group has strong technical strength, introduces the most advanced imported equipment and the most advanced technology at home and abroad, and constantly innovates technology investment and efficient cost control. It has become the first domestic production and production with imported quality and the price is much lower than the equivalent quality.

Service:

1.Pre sale

We have 2 factories and 8 branches, and the quality is guaranteed. We can also provide free small samples. The packaging is packaged in iron pallets and tarps. Products can be delivered quickly.

2. Sale

The surface of our products is smooth and clean, edge shaving, size stamping, standard tray export packaging and quality inspection at the time of sale.

3. After sales

If you have any questions after receiving the goods, please feel free to contact us.

FAQ:

Q1: Are you a factory or trade company?

A1: we are a manufacturter for semi-finished engineering plastic sheet & rod like "

Polypropylene Plastic Sheet,Nylon Sheet,Pa6 Rod,Abs Plastic Sheet,Abs Plastic Sheet ,PP Rod and Sheet, POM Sheet, PC Sheet"etc since 1994.

Q2: Is your sample free?

A2:Yes, our samples are free, but the shipping cost is paid by the buyer.

Q3: What about the MOQ ?

A3:In addition to the sample, the minimum order quantity for a regular size product is 100kgs.

Q4: What about the packing ?

A4: As per factory's exported standard, usually use steel pallets.

Q5: What about the payment term ?

A5:we accept payment by L/C , T/T, usually 30% deposit is requested before production. 50% deposit is request for customzied items.

Q6: What's your delivery time?

A6:For samples: within 1-3 working days; For orders: within 7-30 working days.

Related Keywords