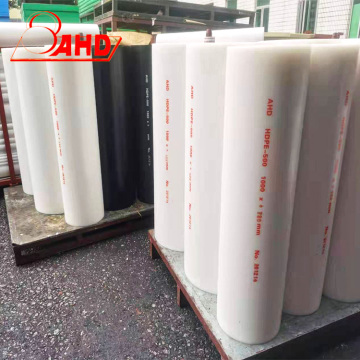

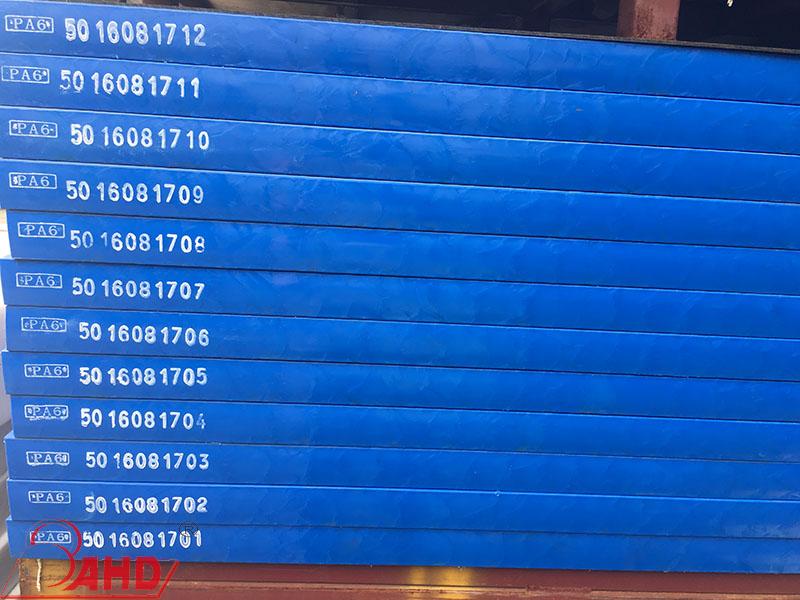

Extruded Blue ColorEngineering Plastic Polyamide PA6 Sheet

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Transportation: | Ocean,Air |

| Port: | Shenzhen |

Pa6 Sheet are tough ridged, have high tensile strength and good resistance to creep, excellent abrasion, chemical and heat resistance and a low coefficient friction. Nylon 6 is used in many structural applications because of its good mechanical strength and rigidity. It is used in bearings because of its good wear resistance.

Main Properties:

- Strong mechanical strength

- High rigidity

- Hardness and stiffness

- Good aging and resistance and mechanical cushioning performance

- Good sliding performance

- Abrasion resistance and creep resistance

- Good machining ability.

- If precisely machining it with proper control, no creeping

- Good abrasion resistance

- Good dimensional stability

Advantage:

- better ductility (due to higher toughness)

- better long term heat resistance

- better impact resistance in low temperatures

- better surface quality

- better creep resistance

- better UV-resistance (depends on modification)

- lower cost

Application:

It is widely used for gears and component of chemical machinery and anti-corrosion equipment, war part, transmission part, parts of domestic appliances, automobile manufacturing, screw rod back-stop machinery and chemical machinery as well as chemical equipment.

Specification:

|

Item name |

PA6 (Polyamide ) sheet |

|

Type: |

extruded |

|

Size: |

1000×2000mm |

|

Thickness: |

8---100mm |

|

Density: |

1.14 g/cm³ |

|

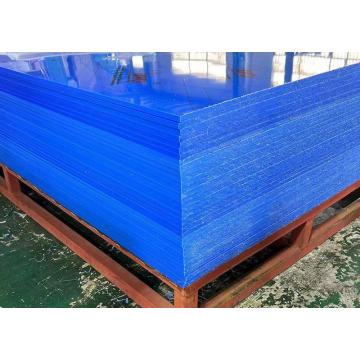

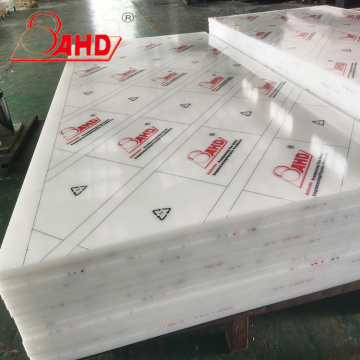

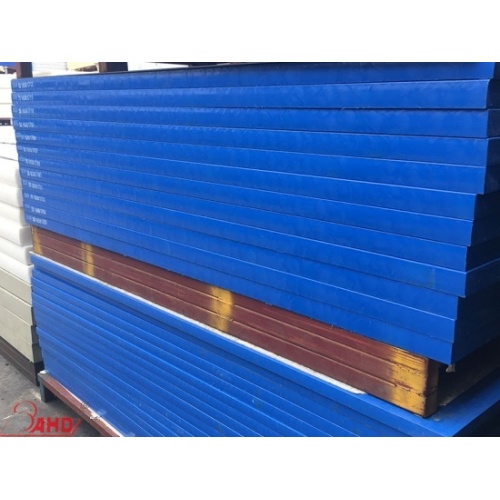

Color: |

White, black, blue |

|

Brand name: |

AHD |

|

Material: |

100% virgin material |

|

Sample: |

FREE |

|

Alkali resistance: |

YES |

|

Carbonated water resistance |

+/0 |

|

Ketone resistance |

YES |

Physical Datasheet:

|

Item |

PA6 SHEET |

|

Color: |

White,black, blue |

|

Proportion: |

1.14g/cm³ |

|

Heat resistance (continuous): |

85℃ |

|

Heat resistance (short-term): |

160℃ |

|

Melting point |

220℃ |

|

Linear thermal expansion coefficient (average 23~100℃): |

90×10-6 m/(m.k) |

|

Average 23--150℃ |

105×10-6 m/(m.k) |

|

Flammability(UI94): |

HB |

|

Tensile modulus of elasticity: |

3250MPa |

|

Dipping into water at 23℃ for 24h |

86% |

|

Dipping into water at 23℃ |

9% |

|

Bending tensile stress/ Tensile stress off shock |

76/- Mpa |

|

Breaking tensile strain |

˃50% |

|

Compressive stress of normal strain-1%/2%: |

24/46 MPa |

|

Pendulum gap impact test |

5.5 KJ/m2 |

|

Rockwell hardness: |

M85 |

|

Dielectric strength: |

25 kv/mm |

|

Volume resistance: |

10 14Ω×cm |

|

Surface resistance: |

10 13Ω |

|

Relative dielectric constant-100HZ/1MHz: |

3.9/3.3 |

|

Critical tracking index(CTI) |

600 |

|

Bonding capacity: |

+ |

|

Food contact: |

+ |

|

Acid resistance: |

- |

|

Alkali resistance |

+ |

|

Carbonated water resistance: |

+/0 |

|

Aromatic compound resistance: |

+/0 |

|

Ketone resistance: |

+ |

Packing & Delivery

Packing Details : Wooden pallets on bottom with PE film coverd

Delivery Details : 7 - 45 days according to the upload time and QTY

Related Keywords