Professional Offer Factory Plastic Polyethylene PE Sheet

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CIF, EXW

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Delivery Time:

- 10- 20 days according to quantity Days

- Transportation:

- Ocean, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | 3000 Ton/Tons per month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CIF,EXW |

| Transportation: | Ocean,Air |

| Port: | Shenzhen |

Professional Offer Factory Plastic Polyethylene PE Sheet

Product Description

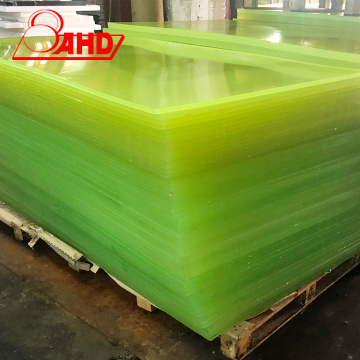

High-density polyethylene (HIGH DENSITY POLYETHYLENE, HDPE) is commonly known as low-pressure polyethylene. Compared with LDPE and LLDPE, HDPE 500 sheet has high temperature resistance, oil resistance, vapor permeability and environmental stress crack resistance. In addition, electrical insulation and resistance Excellent impact and cold resistance, mainly used in blow molding, injection molding and other fields.

HDPE polyethylene sheet produced by Anheda is straight and straight, without air bubbles, and is not easy to break. The thickness can reach 200mm.

HDPE 500 sheet's advantages

- Good Fatigue & Wear Resistance

- Food safe

- Great cutting board material.

- Excellent chemical resistance and corrosion resistant.

- Resists organic solvents, degreasing agents & electrolytic attack.

500 Micron Hdpe Sheet Applications:

- Cutting Boards

-

Hollow products, such as milk bottles, detergent bottles, barrels, cans, tanks

-

Pipe: water pipe

- Wire and Cable

Plastic HDPE Sheet 's Physical Datasheet:

|

Item |

Hdpe 500 Sheet |

Unit |

|

Density |

0.96 |

g/cm3 |

|

Max Continuous Operating Temp: |

90 |

℃ |

|

Max Short Term Operating Temp: |

110 |

℃ |

|

Flexural Strength |

21.3 |

MPa |

|

Flexural Modulus |

837 |

MPa |

|

Charpy Notched Impact Strength |

35 |

KJ/m2 |

|

Tensile Modulus |

851 |

MPa |

|

Tensile Strength |

24.8 |

MPa |

|

Nominal Tensile Strain at Break |

630 |

% |

|

Izod Notched Impact Strength |

33 |

KJ/m2 |

Our company

Anheda Plastic Group(AHD) was established in 1994 in the first special economic zone in Shenzhen, China. As the earliest manufacturer of engineering plastic semi-finished products, the group was founded with the mission of providing customers with the most competitive products. The Group has strong technical strength, introduces the most advanced imported equipment and the most advanced technology at home and abroad, and constantly innovates technology investment and efficient cost control. It has become the first domestic production and production with imported quality and the price is much lower than the equivalent quality.

Packing And Delivery:

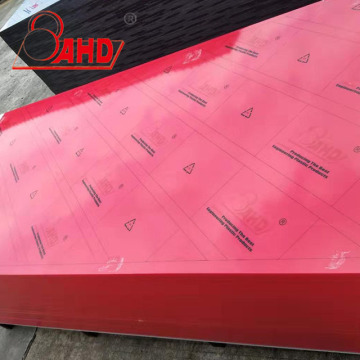

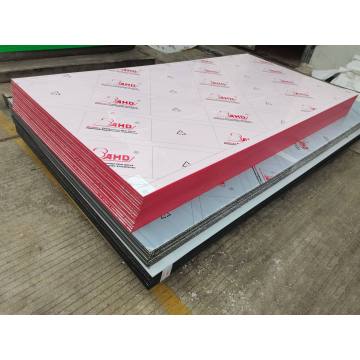

1.One pcs sheet packing: covered with craft paper or PE film,the covered film with AHD logo.

2.With pallet bulk cargo packing: 1.5-2 tons per pallet, use Iron pallets on bottom, with packaging waterproof fabric ,film packages and all around ensure transportation security and prevent damage for the products.

3.Full container load packing: 20-26 tons of a 20 foot container with 10 -12 pallets .

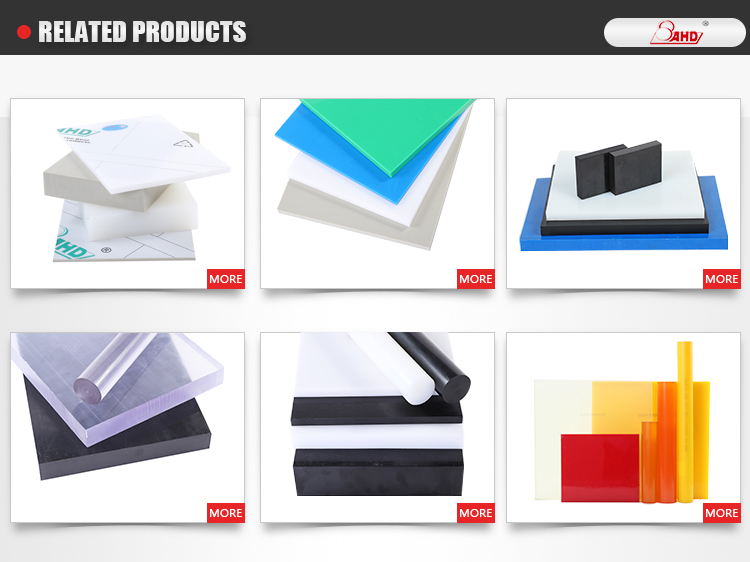

Related Products

AHD Exhibitions

FAQ:

Q1: Are you a factory or trade company?

A1: we are a manufacturter for semi-finished engineering plastic sheet & rod like "

Polypropylene Plastic Sheet,Nylon Sheet,Pa6 Rod,Abs Plastic Sheet,Abs Plastic Sheet ,PP Rod and Sheet, POM Sheet, PC Sheet"etc since 1994.

Q2: Is your sample free?

A2:Yes, our samples are free, but the shipping cost is paid by the buyer.

Q3: What about the MOQ ?

A3:In addition to the sample, the minimum order quantity for a regular size product is 100kgs.

Q4: What about the packing ?

A4: As per factory's exported standard, usually use steel pallets.

Q5: What about the payment term ?

A5:we accept payment by L/C , T/T, usually 30% deposit is requested before production. 50% deposit is request for customzied items.

Q6: What's your delivery time?

A6:For samples: within 1-3 working days; For orders: within 7-30 working days.

Related Keywords