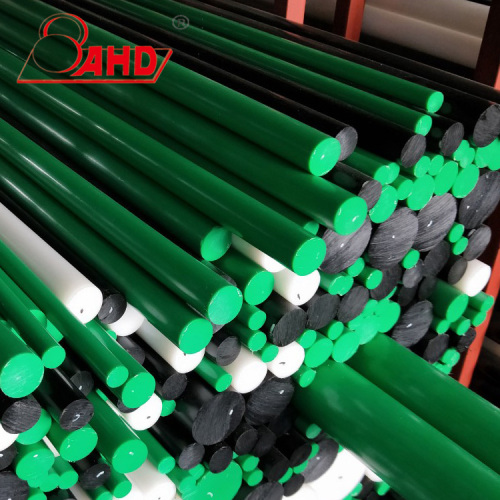

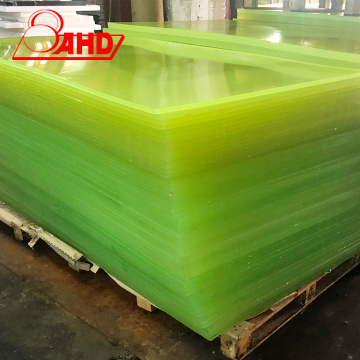

High Density Polyethylene Rod 1000mm 2000mm HDPE Plastic Rod Bar

-

$2.35≥500 Kilogram

- Min. Order:

- 500 Kilogram

- Min. Order:

- 500 Kilogram

- Transportation:

- Ocean

- Port:

- SHENZHEN

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | CHINA |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Certificate: | ISO9001:2015 |

| Transportation: | Ocean |

| Port: | SHENZHEN |

Product Description

Product Description

I. Product Overview

HDPE Rod is manufactured through the extrusion molding process using high-density polyethylene (HDPE). HDPE is obtained by the polymerization of ethylene monomers. Its unique molecular structure endows HDPE Rod with excellent characteristics such as high strength, high toughness, good wear resistance, excellent chemical stability, low-temperature resistance and easy processability. It is widely used in numerous fields like the chemical, food industries, etc., and is a crucial material that supports the development of various industries and meets diverse application requirements.

II. Product Characteristics

Excellent Mechanical Properties

- Both High Strength and High Toughness: It has good tensile and bending strength, capable of withstanding large external forces and impacts. It is used in mechanical transmission and support components to ensure the smooth operation of equipment, such as conveyor belt rollers and guide rails of automated equipment.

- Excellent Wear Resistance: With a moderate surface hardness, a low coefficient of friction and self-lubricating property, it suffers little wear, prolongs the service life of components and reduces costs. It is suitable for easily worn parts in food processing and textile machinery.

Outstanding Chemical Properties

- Strong Corrosion Resistance: It can tolerate most acids, alkalis and salts, and resist chemical erosion under certain conditions. It is used in chemical pipelines, containers and laboratory apparatuses.

- Excellent Water Resistance: It hardly absorbs water and remains stable in humid or water-related environments. It is used in water conservancy projects, underwater equipment and components of marine aquaculture.

Stable Physical Properties

- Low Density and Light Weight: Compared with some materials, it has a lower density and is lighter in mass, facilitating handling, etc. It is used in aerospace and lightweight automotive components.

- Good Insulation Property: It is an electrical insulator, ensuring the safety of electrical systems. It is used in insulation parts of electronic appliances and wire and cable sheaths.

- Outstanding Low-Temperature Resistance: It maintains good flexibility and performance at low temperatures, and is used in cold chain logistics, facilities in cold regions and freezing food processing equipment.

Good Machining Properties

- Easy to Cut: With a uniform material texture and low cutting resistance, conventional cutting tools can be used to process complex and precise parts, meeting the requirements of precision manufacturing, such as mechanical gears and shaft sleeves.

- Excellent Thermoforming Property: When heated appropriately, it has strong plasticity and can be made into special-shaped structures to meet design requirements. It is commonly used in elbows of plastic pipelines.

III. Product Application Areas

Chemical Industry

- Pipelines and Containers: It is used in pipelines for transporting chemical fluids and containers for storing high-risk chemicals, providing corrosion resistance and ensuring safety.

- Reactor Components: Components such as agitator paddles of reactors use this material, which can withstand reaction conditions, improving production efficiency and product quality.

Food Industry

- Components of Processing Equipment: Food conveyor belts, etc. use this material. It is non-toxic, meets standards, and has good wear resistance, ensuring hygienic safety and improving efficiency.

- Packaging Aids: It is used as seals and inner linings of food packaging to ensure sealing and freshness.

Machinery Manufacturing Industry

- Transmission Components: Gears and other transmission parts are manufactured, which can reliably transmit power and reduce energy consumption, and are used in various industrial machines.

- Support and Guide Rail Components: Guide rails of automated production lines, etc. use this material. With low friction and high toughness, it ensures the high-precision operation of equipment.

Environmental Protection Field

- Sewage Treatment: Aeration pipes of sewage treatment plants, etc. use this material. It is corrosion-resistant and wear-resistant, improving the efficiency and service life of equipment and reducing costs.

- Waste Treatment: Anti-seepage membranes of landfills, etc. use this material. It has chemical stability and anti-aging properties, protecting the environment and improving durability.

Marine Industry

- Marine Aquaculture: It is used as frames of aquaculture cages, etc., resistant to seawater and waves, reducing costs and increasing benefits.

- Marine Engineering: Auxiliary components of offshore platforms use this material to ensure safe and efficient operation.

Related Keywords

Related Keywords