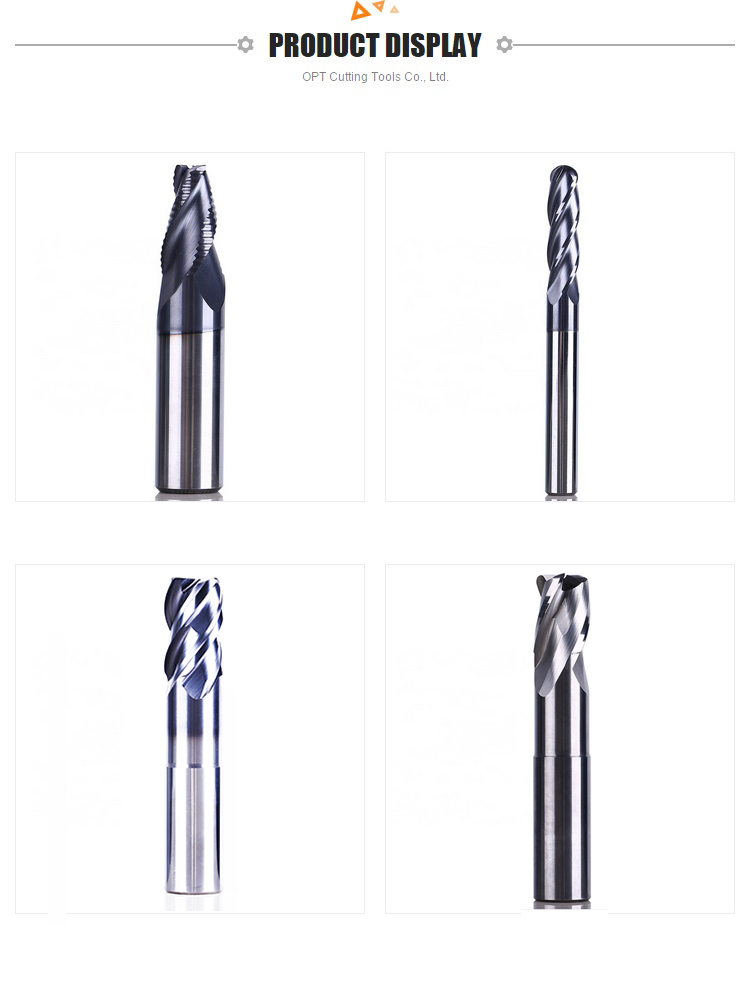

CNC carbide roughing end mills

-

USD8≥10 Piece/Pieces

- Payment Type:

- L/C, T/T, D/P, Paypal, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian, Shekou, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 8000 pcs/month |

| Supply Ability: | 8000 pcs/month |

| Payment Type: | L/C,T/T,D/P,Paypal,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Certificate: | ISO9000 |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian,Shekou,Chiwan |

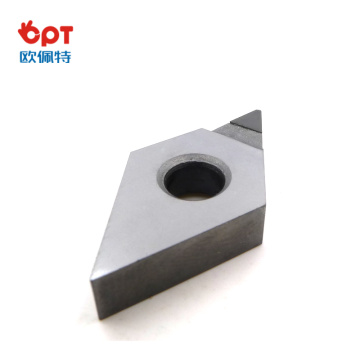

OPT Unequal helix-angle end mill

Carbide tools are the leading products of CNC machining tools. In some countries, more than 90% of turning tools and more than 55% of milling tools are made of cemented carbide. This trend is increasing. Since the 1980s, the tool industry has continuously expanded the production of various integrated and indexable carbide tools or inserts, and its variety has expanded to the field of various cutting tools.

Turning tools and face milling tools have been expanded to various precision, complex and forming tools. Cemented carbide is also a common material for general-purpose tools such as drills and face milling cutters. At the same time, complex tools such as reamers, end mills, medium and large-modulus gear cutters and broaches that process hard tooth surfaces are increasingly using hard alloys. The annual output value of cemented carbide tools and inserts has accounted for more than 30% of the total output value of cutting tools.

OPT cutting tools offers a variety of cutting tools for your application, including the option for customized tools. When ordering any kind of carbide tap, we recommend indicating the material to be tapped so that we can ensure you are purchasing the correct type based on the material of your application.

It is important to work with a company that has in depth knowledge of cutting tools manufacturing. To ensure all technical elements are communicated accurately, we can provide precise specification drawing, samples as well as pre-production samples so the bulk production meets your design. Send us your drawing or request advice for your tool.

Appliction material:

Carbon steel, Tool steel, Alloy steel and Stainless steel.

Advantage:

Machining efficiency is high, the cutting resistance is small, the tool lifetime is long.

Features

Muti flute can be designed

Excellent wear resisance

Application in high speed maching, wet and dry cutting condition

Flexible in order quantity:

Samples can be provided before mass production, and MOQ can be discussed accordingly.

Related Proudcts:

PCD Reamers>>

PCD Reamers>>

Carbide Taps>>

Carbide Taps>>

Quality control:

We have dedicated team of quality control and art equipment to keep good and stable performance for our products.

OEM/ODM Service:

Customization cutting tools is an easy process when partnering with OPT. From drawing to tooling completion takes no longer than 4 weeks. With a sample profile, a CAD file or a dimensioned sketch, we design precision profile tooling with safety, accuracy, exceptional performance and our customer`s complete satisfaction in mind.

Our Service:

- sample is available for testing before ordering

- Customer oriented

- After sale replace service

- Full stock available for urgent demands

ABOUT US :

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Related Keywords