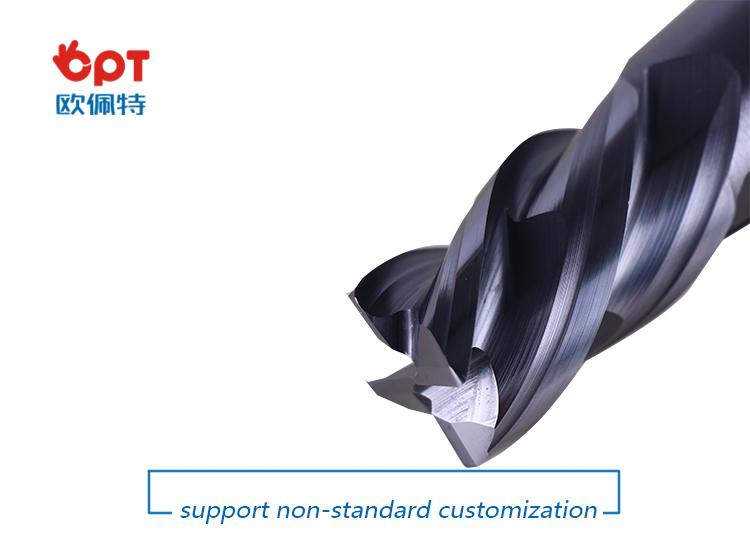

Flat end mills 2 4 6 flutes

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian, Shekou, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 pcs/month |

| Supply Ability: | 10000 pcs/month |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian,Shekou,Chiwan |

Flat end mills 2 4 6 flutes

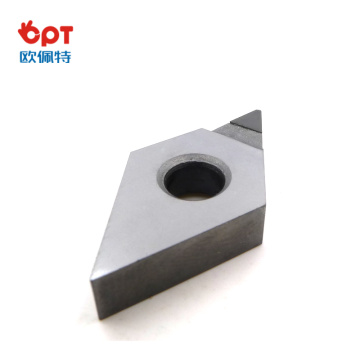

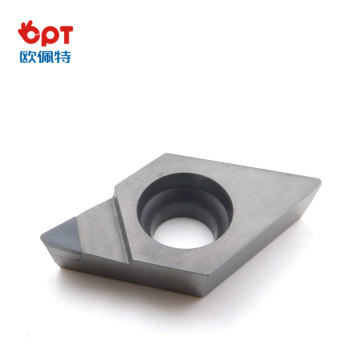

Processing range: milling of aluminum alloy, copper alloy, etc.

Tungsten steel tools (hard alloy) have the advantages of high hardness and wear resistance, high precision and high stability. The milling cutter is mainly used for the process of milling plane, step, groove, forming surface machining and cutting workpiece. Our aluminum milling cutter has a chip flute width and a small cutting edge notch, which can ensure the smoothness of the processed aluminum alloy products. ;

Product application range: aluminum alloy, copper alloy and other soft metals, cutting speed can reach more than 500M;

2. The main geometric angle and function of the end mill The end mill has one more cutting edge. Therefore, in addition to the front angle and the back angle, there are: 1 main declination Kr: the angle between the main cutting edge and the machined surface. The change affects the length of the main cutting edge to participate in the cutting, changing the width and thickness of the chip

2 declination Krˊ: the angle between the minor cutting edge and the machined surface. The role is to reduce the friction of the secondary cutting edge and the machined surface, and affect the polishing effect of the minor cutting edge on the machined surface

3 edge inclination angle λs: the angle between the main cutting edge and the base surface. Mainly functions as a beveled blade. Section 4 Forming Milling Cutter The forming milling cutter is a special milling cutter for forming the forming surface. Its blade profile needs to be designed according to the contour of the workpiece to be machined. It can be machined on a universal milling machine. The complex shape of the surface ensures a consistent shape and high efficiency, and is widely used in batch production and mass production.

Advantage:

One tool for many materials as well as hardened steel

Cost effective tools

Features

2 or 4 flute solid nose ball end mills

Roughing as well as finishing cutters

A selection of various coating

Suitable for regrinding

Flexible in order quantity:

Samples can be provided before mass production, and MOQ can be discussed accordingly.

| F.D | Shank Dia. | O.A.L | Flute Length | Flute | Modle No | |

| D1(h9) | D2(h6) | L1 | L2 | Z | Uncoated | Coated |

| 3 | 4 | 57 | 8 | 4 | LX43L-030 | ■ LX43L-030T |

| 4 | 4 | 57 | 11 | 4 | LX43L-040 | ■ LX43L-040T |

| 5 | 6 | 57 | 13 | 4 | LX43L-050 | ■ LX43L-050T |

| 6 | 6 | 57 | 13 | 4 | LX43L-060 | ■ LX43L-060T |

| 7 | 8 | 63 | 16 | 4 | LX43L-070 | ■ LX43L-070T |

| 8 | 8 | 63 | 19 | 4 | LX43L-080 | ■ LX43L-080T |

| 9 | 10 | 72 | 19 | 4 | LX43L-090 | ■ LX43L-090T |

| 10 | 10 | 72 | 22 | 4 | LX43L-100 | ■ LX43L-100T |

| 12 | 12 | 83 | 26 | 4 | LX43L-120 | ■ LX43L-120T |

| 14 | 14 | 83 | 26 | 4 | LX43L-140 | ■ LX43L-140T |

| 16 | 16 | 92 | 32 | 4 | LX43L-160 | ■ LX43L-160T |

| 18 | 18 | 92 | 32 | 4 | LX43L-180 | ■ LX43L-180T |

| 20 | 20 | 104 | 38 | 4 | LX43L-200 | ■ LX43L-200T |

ABOUT US :

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords