Taper pipe Taps High speed steel alloy steel

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian, Shekow, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000month/pieces |

| Supply Ability: | 10000month / pieces |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian,Shekow,Chiwan |

Taper pipe Taps High speed steel alloy steel

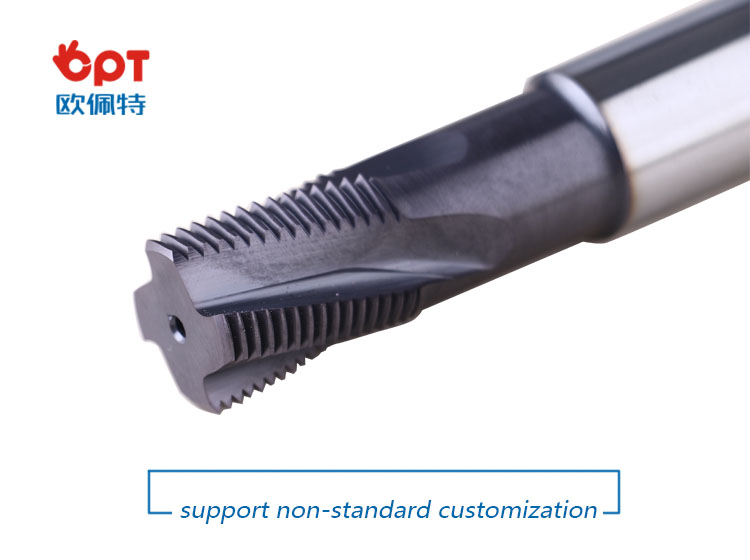

Advantages of thread milling:

1. It is not restricted by the thread structure (external thread/internal thread) and the direction of rotation (left-handed/right-handed). The thread milling cutter of the same pitch can process threads of different diameters, and can also process threads of different sizes and tolerances;

2. The durability of the thread milling cutter is ten or even ten times that of the ordinary tap;

3. The machining accuracy and machining efficiency of the thread milling cutter are greatly improved, and there is no iron filing problem, only short milling chips are produced;

4. It can process deep thread, large thread and large pitch thread with high precision;

5. The thread depth can reach the bottom of the hole, the thread has no axial miscut (overcut), and the cutting force of the thread milling cutter is very small, which is very suitable for the processing of thin-walled parts;

6. High process safety, no need for expensive lubricants;

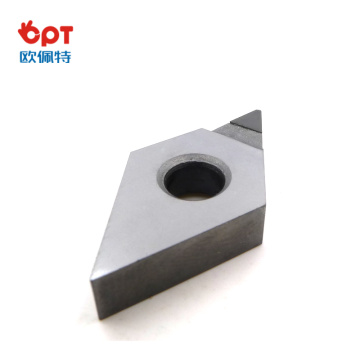

The basic structure of a tungsten steel cone is an axially slotted external thread. The taper angle is 2 on the cutting portion of the tungsten steel cone to distribute the cutting load to several teeth. The correction section has a complete tooth profile to control the thread parameters and guide the tap to move axially. The shank of the shank is connected to the machine tool or the torque is transmitted by a wrench. The tap is axially slotted to accommodate the chips while forming a rake angle. The top edge of the cutting cone and the toothed side edge are scooped to form a relief angle. The center of the tap has a conical shape to maintain the strength of the tap.

ABOUT US :

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords