Coolant Carbide Drills for CNC Machining

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Bag/Bags

- Min. Order:

- 10 Bag/Bags

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Shekou, Yantian

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,FCA |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Shekou,Yantian |

Coolant deep hole of drilling and gun drilling with additional processes designed for specific tolerance objectives and generally performed on BTA-style deep hole drilling machines. Deep hole drilling is used in a variety of materials from aluminum to super-alloys, and is capable of achieving tight diameter control, straightness, and superior surface finish into workpieces.

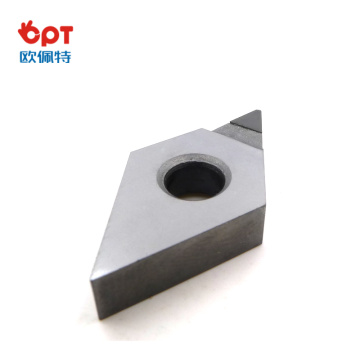

The difference between gold steel drill bit and straight shank twist drill and center drill

Introduction to alloy steel drill bit: Alloy drill bit generally refers to cemented carbide drill bit, which is divided into integral type, welded type, indexable insert type and interchangeable head type. The main components of cemented carbide are tungsten carbide, cobalt, etc. The hardness is generally higher than HRC 90 degrees, which is suitable for batch processing and difficult hard processing. Carbide drill bits are generally considered to be a drill bit for core drilling stations. Simply put, in the work of the core drilling station, the cemented carbide drill bit relies on the impact pressure process and the impact load generated by its own rotation to break the rock. During the entire rock drilling process, the drill bit is often subjected to high-frequency impact loads and is subjected to various composite stresses such as torsion, bending, stretching, and compression, and is subjected to rock, rock powder, and the like in a high-speed rotary collision environment. Wear and corrosion of working media such as mineral water Zy12.

product detail:

| F.D | Shank dia | O.A.L | Flute length | Length of cut section | Model number | |

| D1 | D2 | L1 | L2 | L3 | Uncoted | coated |

| 3 | 3 | 50 | 16 | 12 | ZZ03B-030 | ■ ZZ03B-030T |

| 3.5 | 3.5 | 52 | 20 | 15 | ZZ03B-035 | ■ ZZ03B-035T |

| 4 | 4 | 55 | 22 | 16 | ZZ03B-040 | ■ ZZ03B-040T |

| 4.5 | 4.5 | 58 | 24 | 17 | ZZ03B-045 | ■ ZZ03B-050T |

| 5 | 5 | 62 | 26 | 19 | ZZ03B-050 | ■ ZZ03B-050T |

| 5.5 | 5.5 | 66 | 28 | 20 | ZZ03B-056 | ■ ZZ03B-065T |

| 6 | 6 | 66 | 28 | 19 | ZZ03B-060 | ■ ZZ03B-060T |

| 6.8 | 6.8 | 70 | 31 | 21 | ZZ03B-068 | ■ ZZ03B-068T |

| 7 | 7 | 75 | 34 | 24 | ZZ03B-070 | ■ ZZ03B-070T |

| 7.5 | 7.5 | 75 | 34 | 23 | ZZ03B-075 | ■ ZZ03B-075T |

| 8 | 8 | 79 | 37 | 25 | ZZ03B-080 | ■ ZZ03B-080T |

| 8.5 | 8.5 | 79 | 37 | 24 | ZZ03B-085 | ■ ZZ03B-086T |

| 8.8 | 8.8 | 79 | 37 | 24 | ZZ03B-088 | ■ ZZ03B-088T |

| 9 | 9 | 84 | 40 | 27 | ZZ03B-090 | ■ ZZ03B-090T |

| 9.5 | 9.5 | 84 | 40 | 26 | ZZ03B-096 | ■ ZZ03B-095T |

| 10 | 10 | 89 | 43 | 28 | ZZ03B-100 | ■ ZZ03B-100T |

| 11 | 11 | 95 | 47 | 31 | ZZ03B-110 | ■ ZZ03B-110T |

| 12 | 12 | 100 | 51 | 33 | ZZ03B-120 | ■ ZZ03B-120T |

| 14 | 14 | 107 | 54 | 33 | ZZ03B-140 | ■ ZZ03B-140T |

| 15 | 15 | 111 | 56 | 34 | ZZ03B-150 | ■ ZZ03B-150T |

| 16 | 16 | 115 | 58 | 34 | ZZ03B-160 | ■ZZ03B-160T |

| 17.5 | 17.5 | 123 | 62 | 36 | ZZ03B-175 | ■ ZZ03B-175T |

| 18 | 18 | 123 | 62 | 35 | ZZ03B-180 | ■ ZZ03B-180T |

| 20 | 20 | 131 | 66 | 36 | ZZ03B-200 | ■ ZZ03B-200T |

ABOUT US :

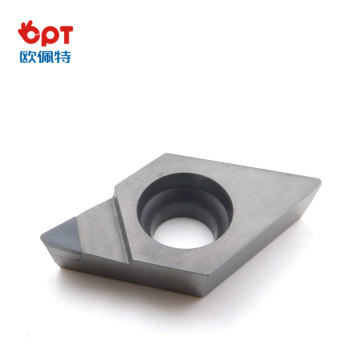

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and

Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing

with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

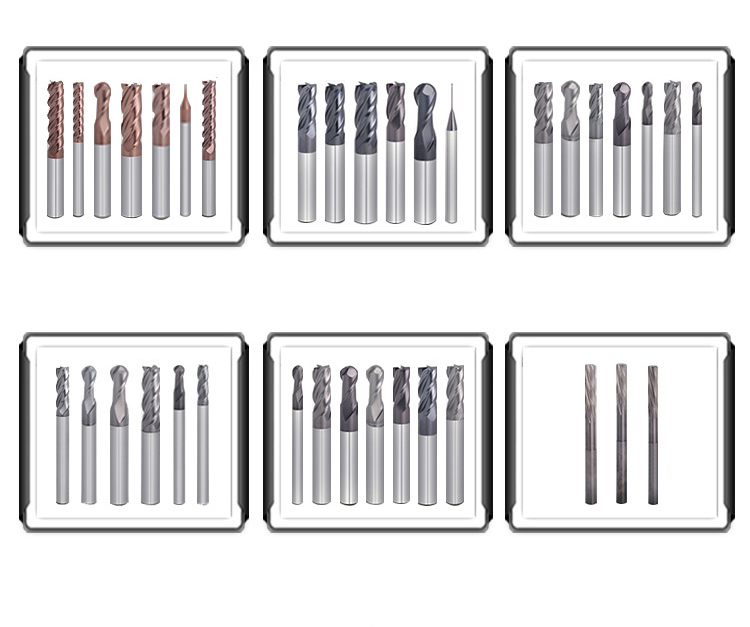

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in

the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords