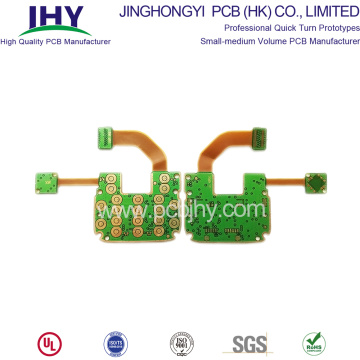

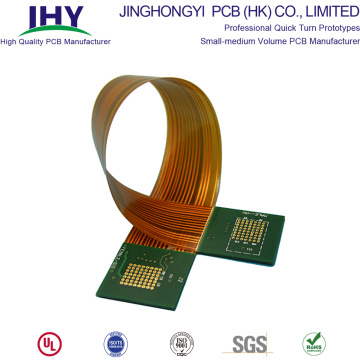

4 Layer Rigid Flexible PCB for Digital Camera

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Air |

4 Layer Rigid Flexible PCB for Digital Camera, Digital Camera FPC, Multilayer Rigid Flex PCB

Rigid flexible circuit boards (Rigid-Flex PCB) are widely used in consumer electronics

Upgrading and innovation of consumer electronics products can not be separated from the support of the FPC flexible circuit board and rigid-flexible circuit board. Since its establishment, Jinghongyi PCB has been focusing on flexible circuit board, rigid circuit board, rigid-flexible PCB, PCB prototype manufacturing, and PCB assembly services. In digital camera FPC, intelligent toy FPC, camera FPC, projector FPC, TV FPC, game machine FPC, robot FPC, LCD TV FPC, audio FPC, lighting FPC, intelligent wearable FPC, and so on, have mature process manufacturing capabilities.

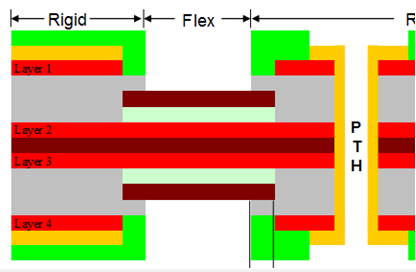

Rigid Flexible PCB: Circuit boards made of flexible substrates and bonded with rigid substrates in different areas. In rigid-flexible binding areas, conductive patterns of flexible substrates and rigid substrates are usually interconnected.

For the use of rigid flexible PCB, it is more widely used in Europe, America and Japan. In Asia, rigid flexible PCB are mostly used in mobile phones.

The rigid-flexible PCB is different from the original flexible PCB and rigid PCB in material, equipment and process. In terms of materials, PCB material is FR4, FPC material is PI or PET, there are some problems between the two materials, such as joint, different shrinkage rates of hot compression, etc. The development space of the rigid-flexible circuit board is very large, it has very good advantages. Although each type and style of circuit boards have certain advantages and disadvantages, what are the advantages of rigid-flexible PCB combination boards?

The advantages of rigid flexible PCB over rigid PCB:

1. It has high and low-temperature resistance, good fire resistance, and can be folded without affecting the signal transmission function.

2. High reliability. The combination of rigidity and flexibility can replace the connector to ensure high reliability in the harsh environment of vibration, impact and humidity.

3. It can reduce the volume, weight, function, and cost of application products.

4. Shorten installation time, reduce installation cost, facilitate operation, and improve the service life of products.

5. It can prevent electrostatic interference and has flexibility. It can be three-dimensional wiring and change shape according to space limitation.

6. It has rigid PCB strength and can support it.

Rigid-Flexible PCB Applications:

- Computer field: disk drives, transmission lines, notebook computers, printers, etc.

- Communication field: multifunctional telephone, mobile phone, videophone, fax machine, etc.

- Automobile field: control instrument, exhaust hood controller, protective board circuit, circuit breaker system, etc.

- Consumer products: cameras, video recorders, DVDs, microradios, calculators, fitness monitors, etc.

- Industrial control field: laser measuring and controlling instrument, sensor, heating coil, photocopier, electronic weighing apparatus, etc.

- Instrument field: NMR analyzer, X-ray device, infrared analyzer, etc.

- Medical machinery field: physiotherapy instrument, cardiac pacemaker, endoscope, ultrasonic control instrument, etc.

- Aerospace field: satellite, radar, radio communication, missile, etc.

1. Output Advantage

- Strong production strength, to meet the batch needs of different customers

- The company's own plant covers an area of nearly 12,000 square meters and employs more than 500 people. It has introduced advanced equipment and production technology from Germany, Japan, and Taiwan. Its monthly output is as high as 15,000 square meters.

- For a long time, the company has formed a complete set of production processes, and the production is becoming more and more specialized, modern and large-scale.

- At present, we have passed the ISO 9001 quality system, UL standard, ROHS standard, and SGS lead-free certification.

2. Technical advantages

- Senior R&D team, tailor-made application solutions

- In general, the customer provides Gerber documents, and the senior engineer team of Jinghongyi PCB will audit and optimize them free of charge.

- Customers with special requirements can provide personalized solutions and related technical support according to their needs and practical experience.

3. Service Advantage

- Double-line production mode, one-stop supply is guaranteed

- Our company adopts two-line production, one is a mass production line, the other is special emergency line for development company. The double-sided PCB Prototype can be as fast as 24 hours, 48 hours for four layers, 72 hours for six layers, and so on.

- Production of double-sided PCBs in 5-6 days and multi-layer PCBs in 7-9 days after formal orders are received.

- Urgent order can be delivered as soon as 3 days to fully meet customer's time requirements.

4. Product Advantage

- Strict production and testing, 100% pass rate

- Jinghongyi PCB provides customized products with 1-8 layers of different thicknesses, different materials, and different processes, in which the core plate is made of grade A military raw materials, and the quality is guaranteed.

- Eight Surface Treatment Technologies + High-Quality Ink Printing, Beautiful and Reliable Upgrade;

- Implement quality PDCA cycle process, strictly control in accordance with IPC standards, ensure the delivery quality pass rate.

- After the open/short circuit test, impedance test, solderability test, thermal shock test, metallographic micro section analysis, halogen-free test and dozens of other tests.

5. Process Advantage

- Minimum linewidth/spacing: 0.05mm (1/3oz)/0.045mm (1/4oz)

- Minimum through-hole pad: 0.3mm

- Cover face alignment tolerance: 0.2mm

- Profile tolerance: 0.05 mm

- Maximum number of layers: 8 layers

- Pitch tolerance: +/-0.05mm

- Minimum laser control: 0.1mm

Equipped with a complete set of surface treatment equipment, it can fully meet the needs of Immersion Gold, immersion silver, Gold plating, OSP and other related requirements, effectively control the risk of process outsourcing.

6. Especially configure SMT production line to provide one-stop flexible circuit board service for customers!

- There are 20 SMT production lines of world-famous brands to reduce supply chain links for you

- Specially equipped with SMT burning test equipment for the floppy board to meet the special requirements of the industry

Technology at Your Fingertips

Our printed circuit board manufacturers specialize in different areas of PCB manufacturing, giving us the unique ability to not only build your boards economically, but to also maintain the highest quality standards. Because of our high order volumes we have negotiated pricing much lower and we believe you cannot find a better value anywhere else.

What we can do?

1.PCB production service. Available on CEM-1,CEM-3, FR-4, TG150-180, Aluminum, Rigid, FPC

2. PCB and PCBA manufacturing and copy service (PCB and PCBA reverse engineering service)

3. PCB assembly service. Available on SMT, BGA, DIP.

4. End products assemble. Available on Final Functional testing and final package

5. Electronic Components purchasing service

6. PCB and PCBA design service

The Boards we can make are High Frequency PCB, PCB Assembly one-stop service, Flexible PCB, Rigid-Flex PCB, Prototype PCB, LED PCB, Quick Turn PCB, Multilayer PCB, High Tg PCB, etc.

Capability

Bare PCB Lead Time

|

Layer

|

Sample Order

|

First Order

|

Mass production

|

|

Quick turn

|

Usual time

|

(above 30 m2) | |

|

2

|

24 hours

|

3-4 days

|

8-10 days

|

|

4

|

48 hours

|

5-6 days

|

10-12 days

|

|

6

|

72 hours

|

6-8 days

|

12-14 days

|

|

8

|

72 hours

|

8-10 days

|

16-18 days

|

|

10

|

96 hours

|

12-12 days

|

18-20 days

|

|

......

|

......

|

......

|

......

|

PCB Assembly Lead Time

Packing and Delivery

Related Keywords