Halogen-Free PCB Manufacturing and Fabrication Service

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

Halogen Free PCBs - Halogen Free Printed Circuit Boards

Agenda

- How do we define halogen-free and halide-free?

- What is the Halogen?

- What is Halogen Free PCB?

- Properties of Halogen Free PCB's

- Why use halogen-free PCB?

- Halogen Free PCB material

- Halogen-Free PCB Applications

-

Halogen Free PCB Manufacturing and Fabrication

How do we define halogen-free and halide-free?

Both halogens and halides can be found in trace amounts as impurities in many materials.

The term"Halogen-Free", much like the term "Lead-free", does not necessarily indicate a complete absence of Halogens.

Therefore, upper limits for the presence of these materials have been set by the following organizations:

The International Electrochemical Commission defines halogen-free as:

- <900 ppm chlorine

- <900 ppm bromine

- <1500 ppm total halogens

IPC defines halide-free as:

- < 500 ppm of a flux's solids content, as chloride (fluoride and bromide are adjusted for molecular weight difference and calculated as chloride).

A halogen is a chemical element that is found in many electronic components and is the focus of systematic regulatory elimination. In many cases there are no simple drop-in replacements for halogenated materials.

What is the Halogen?

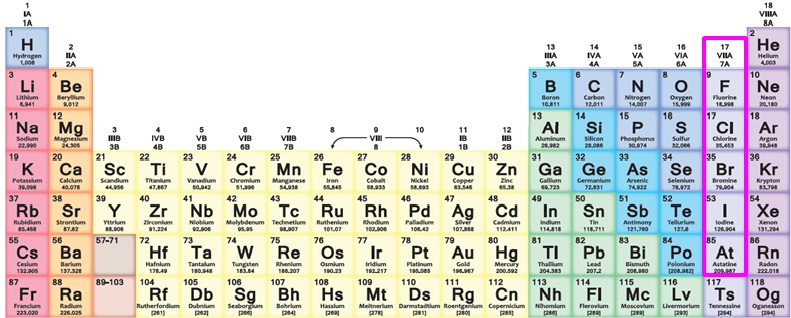

Halogens are the elements in group VII including fluorine (F), chlorine (Cl), bromine (Br), iodine (I), and astatine (At), as marked in the following figure.

The name halogen was from the Greek roots hal- ([salt") and -gen ([to produce"). They all produce sodium salts in similar properties. Halogens easily dissociate into ions and combine with surrounding elements to form compounds due to their high levels of electronegativity. Bromine and chlorine compounds are widely used as flame retardants in electronic industry because of the following advantages: high flame retardance, ease of blending, good compatibility with electronic materials, good electrical insulation, and cost.

What is Halogen Free PCB?

Halogen-free PCB boards are made of halogen-free raw materials. The PCB boards produced are called halogen-free PCB boards. Halogen-free board is an environmental protection material.

Halogen free PCB's are those that have very low or negligible content of Halogens in them. Chlorine and bromine are the primary elements that make Printed Circuit Boards toxic in nature. When boards made out of these materials are subjected to high temperatures, they release harmful gases in to the atmosphere. For a PCB to be halogen free, it should have less than 900 parts per million of chlorine and bromine and less than 1500 parts per million of total halogens in them.

There is an increasing demand for environment friendly PCB products in electronics industry as they are trying to reduce and eventually eliminate toxic elements. Since Halogens free PCB's do not contain these toxic elements, they have been in high demand.

Properties of Halogen Free PCB's

They don't release harmful gases into the atmosphere unlike halogen PCB's that have high concentration of chlorine and bromine which are toxic for the environment.

Adding Halogen flame retardant to the PCB increases the Dielectric Constant of the material impacting design targets and other design considerations.

Halogen free PCB's have comparatively higher rigidity and lesser strength of the laminate.

They have lower machinability of the laminate that affects processing cost and via reliability.

Why use halogen-free PCB?

What is the Importance of a Halogen-free Printed Circuit Board?

Environmental and Health Issues

The main reason for using halogen-free PCB is environmental protection.

Flame retardant is a heavy topic.

Halogenated polymers or flame retardant mixtures composed of halogenated polymers and halogenated flame retardants have excellent flame retardancy and have been widely used as flame retardants.

However, when fire occurs, this kind of halogenated flame retardant material will produce a large amount of smoke and toxic corrosive hydrogen halide gas, causing secondary hazards. The new flame retardant system has low smoke and no toxic and corrosive gases. Halogen-free flame retardant additives are mainly phosphorus compounds and metal hydroxides. These two kinds of compounds, which do not volatilize and produce corrosive gases during combustion, are called pollution-free flame retardants. In addition, there are some new halogen-free flame retardants, such as silicon flame retardants and nitrogen flame retardants.

Halogen-free flame retardant is to add appropriate halogen-free flame retardant in materials to achieve this goal.

During the early days of PCB development, many toxic compounds were used as either a cost-saving aspect of manufacturing or because of the specific, helpful nature of the element. As humanity develops an increased understanding of the threats that past materials present to life in today`s world, manufacturers are changing methods and finding new materials that don`t pose a threat to individuals working with such creations.

Common compounds that are used in PCB developments belong to the family of Halogen elements. Although the composition themselves provide certain benefits to the development of electronics, they are harmful to human life in one way or another.

These elements are:

– Chlorine

– Bromine

– Iodine

– Astatine

While there is still debate on the toxicity of halogens within PCB development, there are two primary elements that constitute the general consensus of a halogen-free circuit board. These two are chlorine and bromine. Each provides a specific benefit to the overall safety and functionality of electronics but pose a threat to the continuity of life for humans and nature.

Environmental Impact of Chlorine and Bromine

Chlorine is used as an antibacterial agent in bleaches and pools and as solvents for cleaning computer chips and circuit boards in electronic industry whereas Bromine is used as a sterilizing agent and as flame retardant in electronics components. Due to these reasons, there use have been kept persistent for so long. However, their harmful effects greatly outweighs the benefits.

On exposure to high temperature, they release toxic gases which leads to coughing, nausea, blurred vision, skin irritation, trouble breathing and burning in the eyes, nose and throat. Prolonged exposure can lead to unconsciousness. They even form deadly chemicals on combination with hydrocarbons. Hence Halogen free PCB`s were introduced to curb the impending danger.

The importance of halogen-free components can be viewed as an effect of the aftermath from disposal of various electronics. While merely handling a PCB will more than likely not affect an individual, it is the incineration and destruction of components that pose the more serious threat. Dioxin is a compound that forms when chlorine-based components are brunt with the addition of hydrocarbons. According to the United States Environmental Protection Agency, dioxin is one of the most toxic chemicals currently known to exist.

Dioxin has been confirmed by the EPA to cause cancer within humans.

While not all printed circuit boards are completely halogen free, let JHYPCB assist you in fabricating your product halogen-free if needed.

The EU RoHS (RoHS is the abbreviation of the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment.)Directive 2002/95/EC, also known as RoHS or Lead-Free, is the Restriction of Hazardous Substances regulation that specifies the maximum levels of lead in various electric and electronic devices. But in reality RoHS restricts more substances then lead. It also restricts the following hazardous materials:

- Lead (Pb): < 1000 ppm

- Mercury (Hg): < 100 ppm

- Cadmium (Cd): < 100 ppm

- Hexavalent Chromium: (Cr VI) < 1000 ppm

- Polybrominated Biphenyls (PBB): < 1000 ppm

- Polybrominated Diphenyl Ethers (PBDE): < 1000 ppm

- The new European RoHS is CE/RoHS certification and the directive is 2011/65/EU.

- European CE-RoHS is compulsory

- China RoHS is a voluntary certification.

- RoHS in USA is voluntary certification and CPSC is compulsory.

- RoHS in Japan is a voluntary test.

Regulations and Legislation

The RoHS directive not only restricts the use of lead in electrical and electronic products, but also other hazardous substances as well.

With the increasing demand for global environmental protection, the use of other hazardous substances is being restricted. For instance, the problems of halogen base compounds are surfacing in the PCB industry because there are quite a lot of halogen containment chemicals utilized in the PCB fabrication process.

Printed circuit boards, solder mask, IC moulding, connectors and other common electronic products contain halogenated compounds, especially PBB and PBDE, which are the most dangerous toxins. That`s why the EU's RoHS regulations prohibit the use of PBB and PBDE.

Going forward, the electronics industry gradually realized that it is necessary to forbid the use other halogenated compounds. Making halogen-free products has now become the latest environmental trend.

Halogen Free PCB material

- High-speed Digital (HSD) materials

- High thermal reliability materials

- RF & Microwave materials

- High density interconnect materials

- NO/LOW flow prepreg materials

- Polyimide materials

- Standard FR-4

- Ceramic for PCBs

- And more

1. Halogen-Free PCB Material Produced by Panasonic

Panasonic has introduced a Halogen-free multi-layer circuit board material Called MEGTRON6.

With the rapid development of 5G, the capacity and speed of this halogen-free PCB material are suitable for 5G system.

Environmental protection has attracted more and more attention. For PCB materials used in communication infrastructure equipment, more and more environmentally friendly halogen-free materials are needed.

Conventionally, the use of non-halogen flame retardants entailed increased transmission loss, particularly in the high-frequency range.

Panasonic's halogen-free material, however, has overcome this challenge by applying its proprietary resin design and compounding technology.

Product Features:

1). Halogen-free material with a low transmission loss characteristic, contributing to higher-capacity and faster data transmission.

2). Enhanced reliability of equipment operation due to highly heat-resistant, high-reliability multi-layer circuit board material.

3). The halogen-free material employed improves ease of manufacturing and processing of multi-layer circuit boards with over 20 layers.

Panasonic another halogen-free laminate material

Panasonic's R-1566W laminate system is Halogen-free and Antimony-free. It meets Lead-free assembly requirements and its applications include Cellular Phones, Personal Devices and Automotive Components.

2. In addition to halogen-free PCB materials produced by Panasonic, there is also a company called isola.

Isola offers a variety of high performance non-halogenated prepregs and laminates to meet the electronic industry's increased performance demands and marketing requirements for environmentally-friendly designs.

Isola materials are engineered for thermal reliability to stand up to the rigors of soldering conditions and chemical resistance to survive etching and plating operations.

| Product | CTE Z-axis | Tg by TMA | Td | Dk | Df |

| P25N | -- | 250 | 383 | 3.67 | 0.0187 |

| P95/P25 | 1.5 | 260 | 416 | 3.76 | 0.017 |

| TerraGreen® | 2.9 | 200 | 390 | 3.44 | 0.0039 |

| TerraGreen® (RF/MW) | N/A | 200 | 390 | 3.45 | 0.0032 |

Features

- Halogen-free materials that meet IPC/JEDEC J-STD-709 for Bromine and Chlorine content

- Lead-free assembly compatible

- Enhanced signal integrity

- Enhanced CAF performance

Typical Applications:

- Transportation

- Mobile and Wireless Devices

- Signal Integrity

- Servers

- High End Computing

3. Commonly used substrates for Halogen-free PCB

Commonly used substrates for Halogen-free PCB are S1155 (FR4) and S1165 (FR4), the following table lists some parameters of those substrates:

| Material | TG | Td | CTE-z | Td260 | Td288 |

| (DSC, °C) | (Wt, °C) | (ppm/°C) | (min) | (min) | |

| S1155(FR4) | 140 | 380 | 41 | 60 | 60 |

| S1165(FR4) | 170 | 360 | 40 | 60 | 15 |

Halogen-Free PCB Applications

You may ask, Do I Need Halogen-Free PCBs, and in what circumstances would i need one??

The short answer is that you probably want all your PCBs to be halogen-free. To understand why, it`s important to know what halogens are. Halogens are elements, many of which historically were used in printed circuit boards, often because it was cost-effective to do so. However, we now know halogens are extremely toxic to humans, and you probably do not want them in your PCBs despite their electronic benefits.

What types of industries and applications are halogen-free PCBs typically used in? Halogen-free PCBs can be used in any industry or application where you would use printed circuit boards, from consumer electronics to industrial automation and everything in between. While there is some variance in the specifications of halogen-free PCBs compared to PCBs which contain chemicals like chlorine and bromine, these boards are entirely effective and suitable for most applications.

If you're concerned about how halogen-free boards will work with your specific application but would still like to try them, feel free to give us a call to discuss the issue. Our PCB experts will be more than happy to talk to you about the differences between halogen-free PCBs and other printed circuit boards, as well as how those differences may or may not affect your specific product.

Although all companies can make use of halogen-free PCBs, they appear most often in companies made a forward commitment to being better to the environment, reducing their carbon footprint and being responsible about the toxins they emit into the atmosphere as a result of their production processes.

For more detailed information, we also recommend the introduction of halogen-free electronic products from the University of Maryland.

Center for Advanced Life Cycle Engineering, University of Maryland, details the impact of halogen-free electronics on health and the environment, Halogen-free Flame Retardants, Impact on Performance, Effect of Moisture and so on.

Halogen Free PCB Manufacturing and Fabrication

JHYPCB brings the same care and expertise to our halogen-free printed circuit boards as we do to all of our PCB products. We offer low-prices, the highest-possible quality ensured by complete and thorough testing procedures and speedy order fulfillment, even on high-volume PCB orders.

When you work with JHYPCB, you can take advantage of our experienced professional designers, who can help you determine if the halogen-free PCB is right for your project, as well as the best way to implement your design. The sooner you get started with JHYPCB, the sooner you can reap the benefits, so be sure to get in touch with us today.

Related Keywords

Related Keywords