Taconic RF-35 High Frequency PCB Board

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Air |

Product Name: Taconic RF-35 High Frequency PCB Board

Base material: Taconic rf-35

Layers: 2

Plate thickness: 0.8 mm

Copper thickness: 1oz

Surface technology: tinning

Application: Communication Equipment

Jinghongyi PCB, a professional PCB manufacturer in Shenzhen, China, We have RF and microwave processing experience, we fully understand your PCB's request. Our engineers studied a variety of RF composite materials, know each performance and processing characteristics, which is the basic foundation of good RF microwave processing. Our material suppliers TACONIC have fast delivery time and quick response service prototype and production requirements, increase your speed to market and competitiveness. There are machining RF and microwave good experience, we can process all kinds of PTFE and other materials

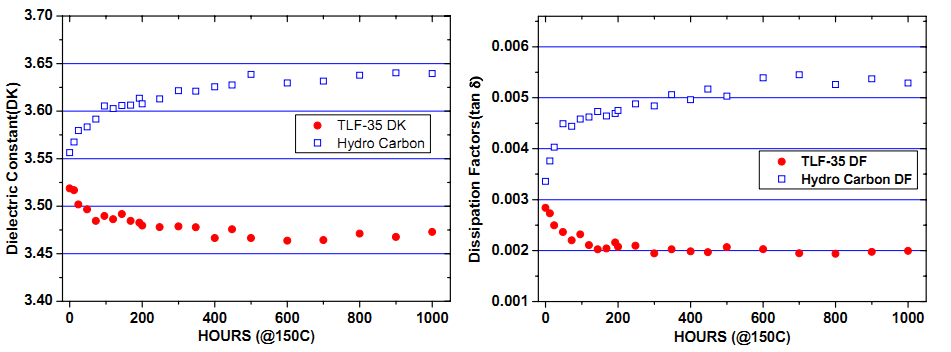

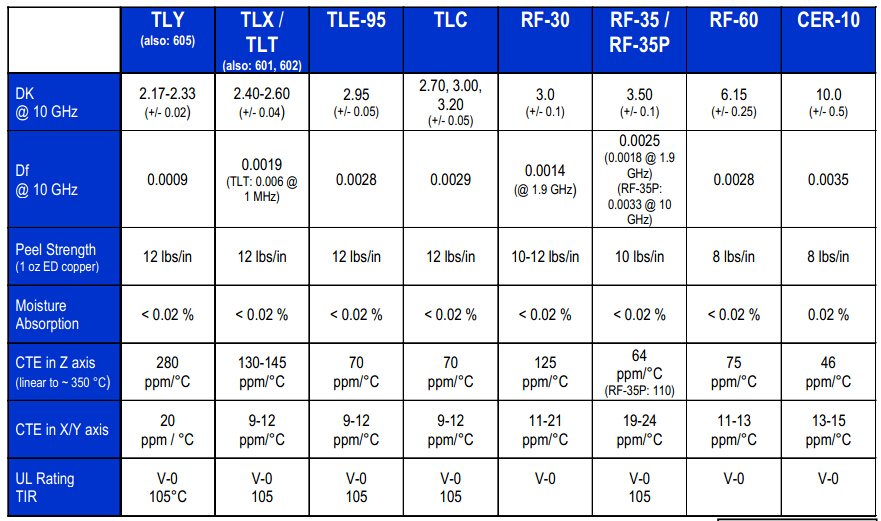

The RF-35 from Taconic is a Laminate with Dk (Dielectric Constant) 3.5 +/- 0.1, Df (Dissipation Factor) 0.0018.

Performance of RF-35 material:

(1) low cost;

(2) Excellent peel strength;

(3) Extraordinary low loss factor;

(4) low water absorption rate;

(5) Enhanced surface smoothness.

(6) General Parameters: Dk (Dielectric Constant) : 3.5 Df (Dissipation Factor) : 0.0018

Application of RF-35 material:

(1) power amplifier;

(2) filters and connectors;

(3) Passive components.

RF-35 is an organic-ceramic laminate material in the ORCER of TACONIC products. It is a reinforced microwave material based on woven glass cloth. RF-35 is a combination of TACONIC's ceramic filling technology and glass fiber coated PTFE technology.

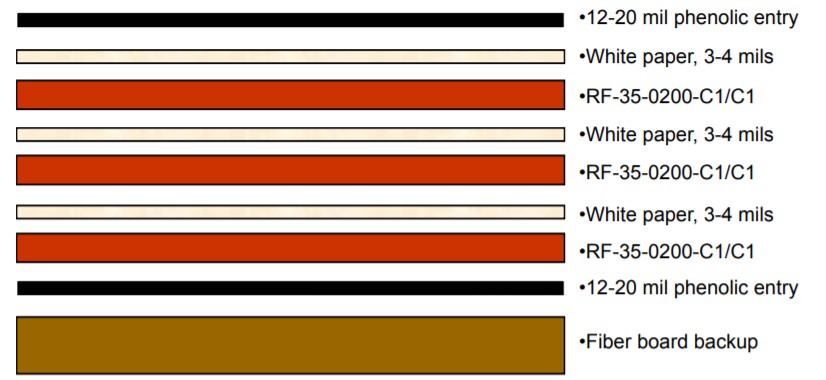

Typical RF-35 Rout Stack-up

RF-35 is the best choice for low cost, high volume commercial microwave and wireless frequency applications.RF-35 1/2 OZ, 1 OZ or 2 OZ copper foil boards offer excellent peel strength, providing rework at any time.

The glass transition temperature of RF-35 exceeds 600 °F (315 °C).

The ultra-low water absorption and low loss factor of RF-35 minimizes phase shift in the frequency range of use.

The dimensional stability of the RF-35 stems from the use of woven glass cloth in its design and development.

The fire rating of RF-35 was tested in accordance with IPC-TM-650, and the flammability test results were V-0.

The standard size of RF-35 material is 36 inch * 48 inch, and the standard thickness are 10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm) and 60mil (1.524mm).

We are one of the professional taconic rf-35 manufacturers and suppliers. RF-35 is the best choice for low cost, high volume commercial microwave and radio frequency applications. RF-35 has excellent peel strength for 1/2 ounce and 1 ounce copper (even in comparison to standard epoxy materials), a critical aspect whenever rework is required. RF-35’s ultra low moisture absorption rate and low dissipation factor minimize phase shift with frequency.

High frequency pcb high-performance insulating material for microwave, radio frequency (RF) and high-speed digital signal processing (DSP) market with PTFE/type woven glass fiber fabric sheet.This material can be applied to LNAs LNBs, PCS/PCN antenna system, global positioning system (GPS) and UMTS antenna system,And the power amplifier, passive components, collision avoidance radar system, aviation help guide remote control technology and system of the phased array radar.

High frequency materials are UL 94V-0 rated for active devices and high power RF designs.

Taconic has been a world leader in the PTFE products since 1961. Today they provide PTFE and silicone coated fabrics, tapes, and laminates for a range of high performance applications. Thermally stable, low Dk, low Z axis CTE PTFE laminates are the focus for the Taconic materials used in the manufacturing of RF/microwave PCBs. Many of the Taconic products are designed with ultra-low fiberglass content to achieve world class insertion loss properties and a homogeneous dielectric constant throughout the laminate.

The uniform dispersion of ceramic throughout the laminate yields extremely low X and Y coefficients of thermal expansion. Taconic has materials for every application and a partial list of their offering.

Taconic Advanced Dielectric branch provides PTFE / woven glass fiber cloth sheet of microwave, radio frequency (RF) and high-speed digital signal processing market. This material can be applied to LNAs, LNBs, PCS / PCN antenna system, global positioning system (GPS) and UMTS antenna system, and a power amplifier, passive components, collision avoidance radar systems, aviation technology and remote assistant director phased array radar system.

Why Choose Us?

Low cost

Excellent peel strength

Exceptionally low DF

Low moisture absorption

Very high thermal reliability

Related Keywords