High Speed PCB Design Layout and Manufacturing

Your message must be between 20 to 2000 characters

Contact NowWhat is a high-speed PCB?

High-speed PCB is a very popular term, so what is high-speed PCB? Probably few people can explain why? Here is our opinion on the term "high-speed PCB".

One viewpoint is that the speed of digital circuit reaches or exceeds 45MHZ~50MHZ, and this part of the speed signal accounts for more than one third of the whole system, so it is called high-speed PCB or high-speed circuit.

At the same time, there is such a phenomenon: when many people mention high-speed PCB, instinctively, I should pay attention to this kind of PCB, otherwise it will easily happen. If my board is not a high-speed PCB board, just do it, no problem!

If we want to build an electronic system now, the highest speed signal is 44.99999999999999 (infinite more than 9) MHz, but this signal drags a long series of loads (such as 80), each branch reaches more than 30 centimeters. Judging from the above point of view, this is not a high-speed PCB (although the number of 9 is a little more, but it is really less than 45MHz!). So full of confidence, oh, this is not a high-speed PCB, do whatever you like, not a high-speed PCB, how can it possibly go wrong? Make prototyping decisively, and the result is...... Well, no result. This PCB can be metamorphosed again! So what about overtime? Re-prototyping? Has the project been delayed? Delayed delivery? Can't get the bonus?

So we have the question: how did the standard of 45MHZ ~ 50MHZ come into being? What is the basis for one third of this value?

We believe that the concept of high-speed PCB is only a very vague comparison in the minds of engineers. Years ago, when digital circuits were just emerging, the speed was really low, and PCBs could basically work as long as they were connected. After that, the signal rate continues to improve. Slowly, the old way of designing PCB is not working. PCB will have problems. With the increase of speed, PCB is prone to problems, and this feeling is constantly strengthened, so the term "high-speed PCB" was born. What is high speed, maybe just a feeling. Later, however, they have to explain it in various ways. We just want to say: there is no need to give a strained interpretation.

One of our views is that concepts are not important for engineering problems. All we're concerned about is making PCBs on time and without any problems. For engineers, debugging should not be so painful. For enterprises, products can be listed in time to seize the market, and for equipment suppliers, timely delivery can avoid losses.

Therefore, we advocate that there is no need to pay attention to the noun concept, we only need to pay attention to: signal distortion distortion, PCB may have problems. For most PCBs, this possibility exists and our goal is to eliminate this risk when designing.

What is a high speed PCB? No answer, we don't need an answer! The emergence of this noun has no practical meaning.

High Speed Circuit Board Design Guidelines

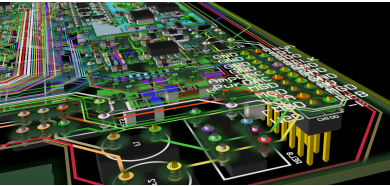

Up to now, there are mainly three design techniques in terms of high-speed PCB design: noise and delayed PCB graph design technique, impedance and propagation delay time control technique and evaluation technique with PCB impedance as parameters among which the latter two types of techniques are the heart of PCB fabrication. There are also a lot of techniques on high-speed PCB fabrication transmissions and the commonly-used basic structures are microstrip and strip line.

It's important for any high-speed PCB to be properly engineered to reduce flaws through elements such as impedance discontinuities in transmission lines, improper plating of the through-hole interconnections or other losses of PCB signal integrity.

General Principles of High Speed PCB Design:

- Power distribution system and its impact on boarding house;

- Transmission Line and Related Design Criteria

- Crosstalk and Its Elimination

- electromagnetic interference(EMI)

- Signal Integrity

Top 10 Tips for High Speed PCB Design

- Always Start Your High Speed Design Process With a Plan

- Document Every Detail of Your Board Stackup for Manufacturing

- Layer stackup Planning – Organize Your Board Into Logical Sections

- Know How to Use Your Power and Ground Planes

- Keep the Size of Your Land Patterns at a Minimum

- Route Your Signals for Maximum Shielding Benefits

- Provide an Efficient Path for Current Return

- Use the 3W Rule to Minimize Coupling Between Traces

- Use the 20H Rule to Minimize Plane Coupling

- Finishing Off With General Routing Guidelines

For the design of high-speed PCB, you can refer to our other articles.

- Signal Integrity in High Speed Circuit Board Design

- Analysis and Processing of Transmission Line Effect in High Speed Circuits

- Re-interpretation of High Speed PCB

- Resistance Termination in High Speed Circuits

- PCB Anti-jamming Design Technology of High Speed DSP

High Speed Circuit Board Raw Materials

As far as materials go, you`ll likely be working with one of these:

FR-4. FR4 material can still be used as the basic material of circuit board successfully, but at higher frequencies, not only dielectric constant but also loss coefficient need to be considered. This is a great material when you're working with clock speeds of < 5Gbps and is classified as a low speed material. FR-4 has a decent ability to control impedance and is also known for its low cost.

Nelco, SI, or Megtron. In the realm of high speed design, you`ll likely be working with these materials. Each is suited for 5-25 Gbps clock speeds.

Rogers. If your first high speed design is pushing 56Gbps, then you`ll likely end up using a Rogers laminate. This is a high frequency, high-temperature material known for good impedance consistency, but it`s also expensive to produce.

High Speed Circuit Board Applications

High-speed PCBs are common in almost every industry that we interact with in our daily lives, from the bank on the corner to the device and infrastructure you`re using to read this article - and that goes double for anyone reading this on a mobile device.

Some of the applications and industries we`ve worked with on high-speed digital PCBs include:

- Network communications for signal integrity verification

- Small-factor layout and design for elements such as radios with a high need for impedance control

- Consumer-facing installed electronics, such as ATMs, which need to be maintained with the latest standards, have high volumes and need a short time-to-market

- High-speed digital test boards for various signals, including tests for RF signal roll-off

- Medical equipment that requires high-speed, extremely dense but low-cost individual PCBs

High Speed PCB Manufacturing Services

Please give us your high-speed PCB production task.

It is also very difficult to manufacture high-speed circuit boards. In order to ensure the normal use of your high-speed circuit boards, we recommend that you choose a supplier with very rich manufacturing experience of high-speed circuit boards.

Jinghongyi PCB is a Chinese supplier with 8 years'experience in manufacturing various PCBs. Our engineers will check your high-speed PCB design and production documents and make reasonable suggestions to save your cost.

There is no minimum order quantity limit in our company. We welcome all customers to make even one piece of PCB prototype, or small and medium batch production. you'll get high-quality engineering support and excellent, on-time delivery performance. We offer competitive pricing, super-fast quote turnarounds and response times that our customers rave about every day.

Relation Resources

Difference between High Frequency Circuit and High Speed Circuit

Related Keywords