8 Layer 1+N+1 HDI PCB

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Air |

Name: 8 Layer 1+N+1 HDI PCB Board

Material: FR-4

Layer: 8 Layer 1+N+ HDI

Color: Black, White

Finished Thickness: 0.8mm

Copper Thickness: inner: 1OZ, ourter: 0.5OZ

Surface Treatment: Immersion Gold+OSP

Min Trace / Space: 3mil/3mil

Min Hole: Mechanical hole 0.2mm, Laser hole 0.1mm

Application: Micro electronic products

The materials we use to produce HDI PCB include: FR4 standard, FR4 high performance, Halogen free FR4, Rogers

Surface finishes available OSP, ENIG, Immersion tin, Immersion silver, Electrolytic gold, Gold fingers.

Our advantage: Multilayer boards with a higher connection pad density than standard boards, with finer lines/spaces, smaller via holes and capture pads allowing microvias to only penetrate select layers and also be placed in surface pads.

For more information about the HDI PCB and the production capacity of our HDI circuit board, please download the PDF file provided by us.

High Density Interconnects (HDI) board are defined as a board (PCB) with a higher wiring density per unit area than conventional printed circuit boards (PCB).

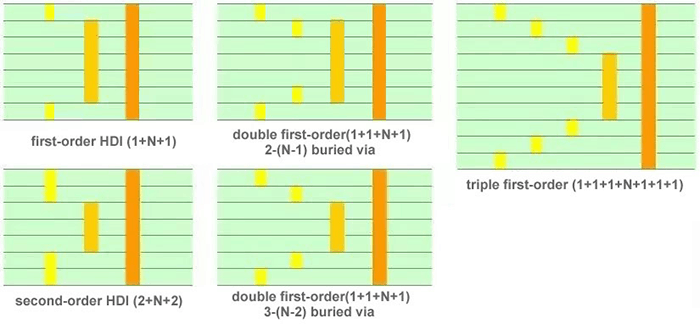

HDI PCB Full Forms:

1+N+1, 2+N+2, 3+N+3, 4+N+4, Any Layer Interconnection

According to layer up different, currently DHI PCB board is divided into three basic types:

1+N+1, 2+N+2, Any Layer Interconnection

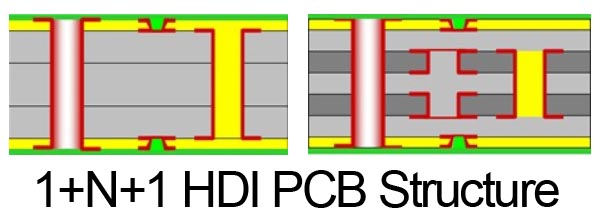

1) HDI PCB (1+N+1)

Features:

Suitable for BGA with lower I/O counts

Fine line, microvia and registration technologies capable of 0.4 mm ball pitch

Qualified material and surface treatment for Lead-free process

Excellent mounting stability and reliability

Copper filled via

Application: Cell phone, UMPC, MP3 Player, PMP, GPS, Memory Card

1+N+1 HDI PCB Structure:

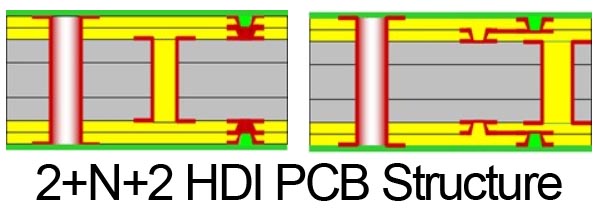

2) HDI PCB (2+N+2)

Features:

Suitable for BGA with smaller ball pitch and higher I/O counts

Increase routing density in complicated design

Thin board capabilities

Lower Dk / Df material enables better signal transmission performance

Copper filled via

Application: Cell phone, PDA, UMPC, Portable game console, DSC, Camcorder

2+N+2-HDI-PCB-structure

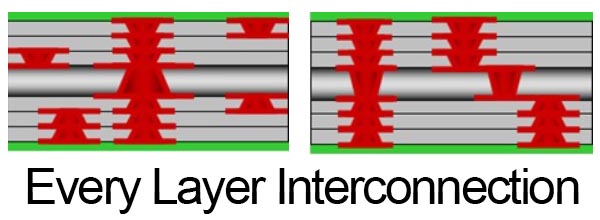

3) ELIC (Every Layer Interconnection)

Features:

Every layer via structure maximizes design freedom

Copper filled via provides better reliability

Superior electrical characteristics

Cu bump and metal paste technologies for very thin board

Application: Cell phone, UMPC, MP3, PMP, GPS, Memory card.

Every Layer Interconnection Structure

The HDI circuit board has the following advantages:

- lower costs

- increase wiring density

- is conducive to the use of advanced packaging technology

- have better electrical performance and signal accuracy

- reliability is better

- can improve the thermal properties

- can improve radio frequency interference, electromagnetic wave interference, electrostatic discharge

- increase design efficiency

Related Keywords