Automatic Plastic Blister Vacuum Forming Molding Machine

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China,shenzhen |

|---|---|

| Productivity: | china,shenzhen |

| Supply Ability: | 10pic/S |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| HS Code: | 8477409000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen Port |

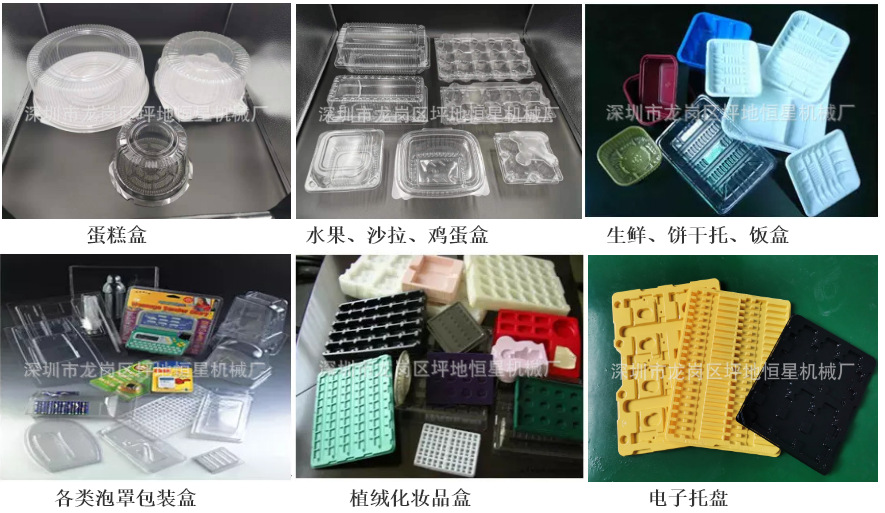

Application:

Vacuum forming machine can be used to produce egg containers, salad boxes, snack boxes, fruit boxes, biscuit boxes, toothbrushes,

batteries, gifts, hardware, stationery, decorations, medical, electronic and other plastic containers.

|

Control type

|

PLC control

|

|

|

||

|

Parameter

|

Forming width

|

480-760mm

|

|||

|

|

Forming length

|

660-1250mm

|

|

||

|

|

Forming height

|

MAX.200mm

|

|

||

|

|

Three choices of one die: 410-660mm, 450-710mm, 480-760mm

|

|

|

||

|

Material

|

Application type

|

PET、PVC、PP、PS、ABS、PC、EVA、CPET, etc.

|

|

||

|

|

Genre

|

Reel feed

|

|

||

|

|

Thickness

|

0.1-2.0mm

|

|||

|

|

|

||||

|

|

|||||

Main Features

(1) Energy saving

a) The heating brick adopts the latest quartz energy-saving heat transfer, saving 20% compared with the traditional heating brick;

b) One-button heating design, the temperature can be set within 1 minute, waiting for 3-5 minutes to produce, ordinary heating brick preheating takes 20-30 minutes to produce.

c) Special heating furnace adjustment function, which can save 1/6 electric energy by misalignment;

(2) Saving materials

a) Adopt variable frequency motor pull-tab, fast drawing speed, transmission error ±1mm, reducing material and power loss;b) Adopt new aluminum + steel beam, purchase material width = mold width + 25-30mm (conventional machine needs + 40-50mm), for example: 180 tons of material per year, calculate according to mold width 600mm, save 10mm by saving material, ie save 1/60 material, saving 3 tons of raw materials per year;

(3) efficient

a) 2P cold air fan, cooling rate is faster; 5P chiller, spray cooling effect is good, can increase production speed;

(4) Data storage

The computer can remember to save the parameters. When the next production, directly call the parameters to reduce debugging time

and improve efficiency.

Machine Size

machine, semi-automatic plastic molding machine, thick plate plastic molding machine, printing positioning plastic molding

machine, high-frequency welding machine. With more than 22 years of production experience, we serve more than 2,000 companies

worldwide. Our products have won high praise from customers all over the world for their high quality and competitive price.

Our Services & Strength

Provide overseas installation and training services,equipment warranty for 1 year

Phone/WhatsApp/WeChat:+8613609629225

Address:No. 43, Yonghong Road, Liulian Fumin Industrial Zone,

Pingdi street, Longgang District, Shenzhen, Guangdong

Related Keywords