Semi automatic thick material blister vacuum forming machine

-

USD147001-0 Set/Sets

-

USD17700≥1 Set/Sets

- Payment Type:

- L/C, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land

- Port:

- Shenzhen, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Yonghong road 43 Liulian Fumin industrial zone, Pingdi Town,Longgang, Shenzhen, Guangdong, China |

|---|---|

| Productivity: | 60 set/sets per year |

| Supply Ability: | If it is urgent,trying our best to shorten the time and the fastest is 25 days |

| Payment Type: | L/C,Money Gram,Western Union |

| Incoterm: | FOB |

| HS Code: | 8477409000 |

| Transportation: | Ocean,Land |

| Port: | Shenzhen,Guangzhou |

Semi automatic thick material blister vacuum forming machine applications

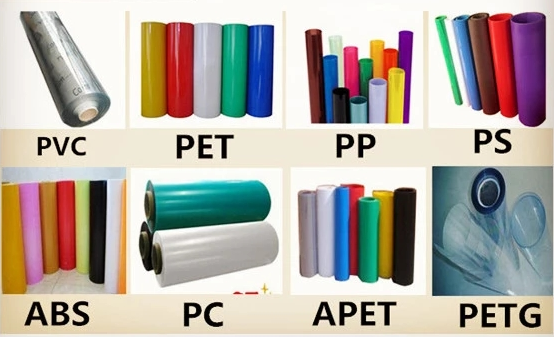

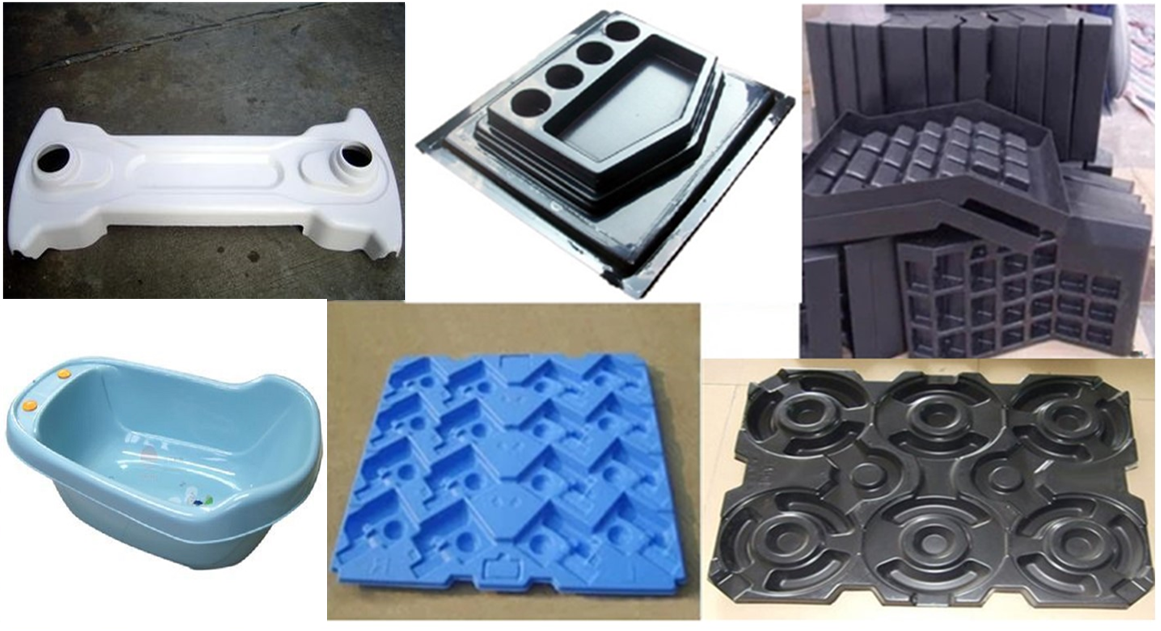

The material such as ABS, PP, PE, PS, PC, PVC, EPS, HIPS, HDPE, PMMA, PET, PETG in thick sheet could be processed by this machine, it is an ideal vacuum forming machine for automobile parts like car foot mat, car trunk mat, car bumper, light box, plastic board, plastic containers, plastic pallet, plastic helmet, plastic covers, bathtub, fruit tray, suitcase, apparatus shell, instrument panel, refrigerator inner liners, etc.

Semi automatic thick material blister vacuum forming machine features

1. The thick material blister vacuum forming machine adopts automatic vacuum forming system.

2. Far infrared ceramic heating bricks or Halogen heater tubes is optional. Halogen heater tube provides rapid heat response with a greater range of control to form challenging shapes and material, infrared ceramic heating brick has longer service life.

3. The thick sheet plastic vacuum forming machine adopts independently controllable heating zones

4. The thick sheet blister vacuum forming machine by adopting universal mold plate, Plastic forming machine for vacuum packing can save material 15%.

5. Lower mould is driven by big cylinder, rack positioning can insure running smoothly.

Semi automatic thick material blister vacuum forming machine

Suitable materials

Detail images

Molding and Samples

Our advantages

Shenzhen Hengxing Machinery Factory was established in 1998, is a Blister Forming Machine, High Frequency Welding Machine and Vacuum Forming Machine manufacturer. Which is located at Yonghong road 43 Liulian Fumin industrial zone, Pingdi Town,Longgang, Shenzhen, Guangdong, China.

We are the leading manufacturer that specializes in designing and manufacturing different kinds of Blister Forming Machine, High Frequency Welding Machine and Vacuum Forming Machine with the experience of more than 20 years, Our products hold high reputation by the clients in the world wide with the high quality and favorable price.

1. Bengal customer buy our machines, and our engineer go to train their workers.

2. Thailand customer buy our machines, and our engineer go to train their workers.

Our Service

1. Professional engineer for guidance and staff training.

2. 24 hours online answer for customer service personnel.

3. One year warranty.

4. We have been engaged in plastic suction machine for more than 20 years, and have rich experience.

5. Training how to instal the machine, training how to use the machine.

6. View our factory on the spot.

Packing and Delivery

|

Selling Units: |

Single item |

|

Single package size: |

270X140X200 cm |

|

Single gross weight: |

2600.0 KG |

|

Package Type: |

Wooden case |

|

Lead Time : |

30 |

Overview`

Quick Details

Condition: New

Type: Vacuum Forming Machine

Plastic Type: PVC,PET,PE,PETG,PS,ABS,Acryl

Product Type: Blister

Place of Origin: Guangdong, China (Mainland)

Brand Name: HENGXING

Model Number: HX-71S

Voltage: AC380 50/60HZ

Power(W): 16KW

Weight: 2500kg

Dimension(L*W*H): 2700*1400 *2000mm

After-sales Service Provided: Engineers available to service machinery

overseas

Machine type: Semi auto

Product: Tray

Material: PVC,PET,PE,PETG,PS,ABS,Acryl

Application: Automobile, Kitchen Appliances

Semi automatic thick material blister vacuum forming machine parameters

|

Model |

HX-71S |

|

|

Power supply |

AC380 50/60HZ |

|

|

Power |

Power |

|

|

Max. forming length |

610mm |

these size can be changed according to customer require |

|

Max. forming width |

610mm |

|

|

Max. forming height |

150mm |

|

|

Material thickness |

1.0-5.0mm |

|

|

Output |

100-200moulds/H |

|

|

Machine size |

2700*1400 *2000mm |

|

|

Net weight |

2500KG |

|

FAQ

1.If I order this machine, and how can

l learn to operate it? Do you offer any help? Would it be charged?

Answer: Shenzhen Hengxing Machinery Factory will

provide our after sales service to our customers. Once you get the machine,

meanwhile you will get our operation instruction which would detailed explain

all about the machine operation. Besides, our operation video is available for

your operation reference. If either instruction or video can not help you, and

we will arrange the our engineer contact you via international telephone

conference

or via face to face mutual video conference.

All above service is free.

The service cost in customers` country was not included if requires oversea

service.

2.About The Warranty:

Answer: One year warranty. Within one year, the initial parts or elements of

the machine broke down cause by the raw material and our hand work, Shenzhen Hengxing Machinery Factory would

replace the parts freely, but the freight charge and the consumable parts like

die, cutting mould were not included. The warranty is not valid if the machine

damage due to customers` wrong operation or caused by force majeure factors.

3.How to order raw material ?

Answer: We can help you to find raw material supplier, and also we can help you

to order if need. And if possible, we will arrange the machine and the raw

material sending to you together.

4..Do you have any other model ?

Answer: Of course . We have different choice for you, and if all our models

that`s not what you want, and you can tell us your details and we can custom

make for you. Or OEM is available.

5.What is the power supply?

Answer : Normally, there are 220v and 380v, and if you need other choice, just

tell us, and we can custom make for you. Or OEM is available.

6.Is this machine need a mould ? Then what kind of mould should it

be? How can I sure the mould is what I need?

Answer: Yes, it needs mould, Cost will be base on the size.

Related Keywords