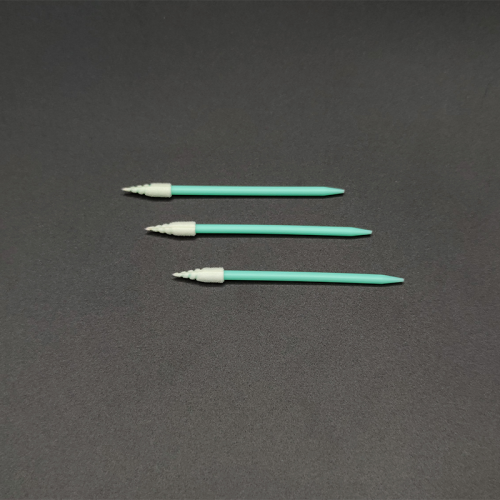

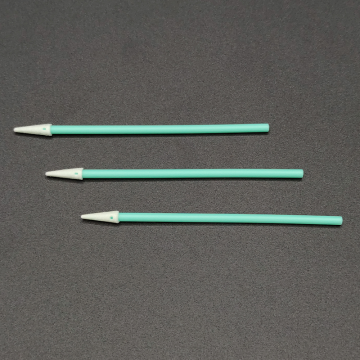

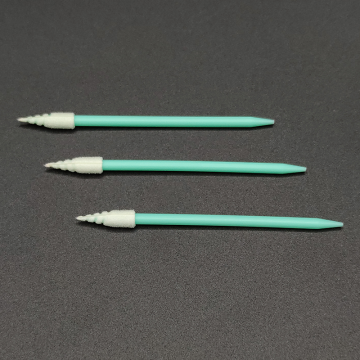

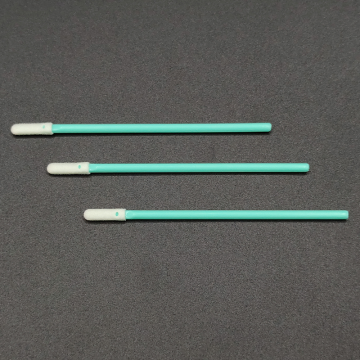

MFS-751 Pointed Head Cleanroom Swabs Sponge for Electronics

- Transportation:

- Ocean, Land, Air, Express, Others

Your message must be between 20 to 2000 characters

Contact Now| Transportation: | Ocean,Land,Air,Express,Others |

|---|

What are the uses of dust-free purification cleaning?

Industrial cleaning, also known as purification cleaning or dust-free cleaning, are dust-free cleaning consumables designed to clean tiny parts in harsh dust-free environments. Using advanced patented technology (DP technology), they are widely used in optoelectronics, semiconductors, and computer hard drives. , medical and other industries.

Industrial cleaning include sponge cleaning, ESD Cleanroom Wiper cleaning, fiber optic cleaning, PU cleaning, paper rod cleaning and other special application wiping sticks; the cleaning head can be made of ESD Cleanroom Wiper and PU materials.

The production process of the ESD Cleanroom Wiper head cleaning should include the automatic knitting, automatic washing and fiber opening, automatic shaping, Foam Tip Swabs, and cleaning pressing of the ESD Cleanroom Wiper at the front end. The process of cutting, collecting and packaging.

Industrial cleaning generally have high-level cleanliness with low dust generation, low NVR and low ion release (without silicon, ammonia, DOP). Solvent performance, can effectively resist the erosion of most solvents.

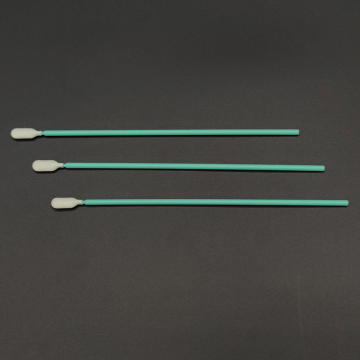

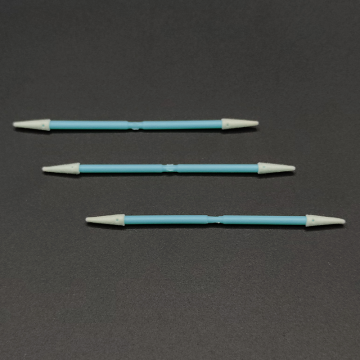

Pointed Head Cleanroom Swabs Sponge Swabs For Electronics

MFS-751 is thermally bonded by 100PPI open-cell polyurethane foam & light green PP handle, its cleanroom laundered foam head possesses high solvent capacity and good cushioning. It is free from organic contaminants such as silicone, amide and phthalate esters, and it features very low non-volatile residue (NVR), ion content and particle generation. MFS-758 is designed with a small compact round handle and a thin flexible paddle head, and it’s the ideal swab for cleaning components in confined thin groove space where thickness height is the major concern.

Product Features

① Free from silicone, amide and phthalate esters

② Low in particles, ion content and non-volatile residue

③ High solvent capacity, soft and non-abrasive

④ Compatible with most common solvents such as IPA

⑤ Designed with flexible head paddle & long compact handle

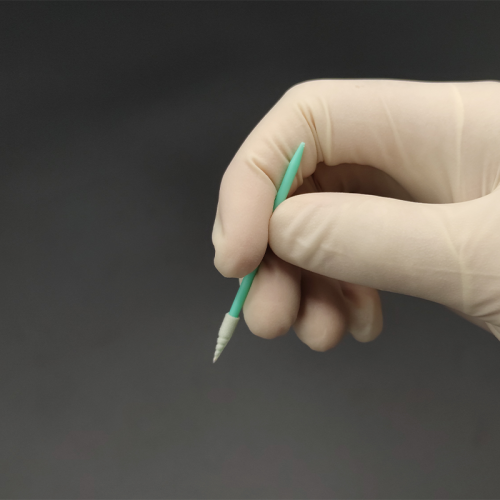

Product Applications

① Cleaning with solvents such as IPA

② Cleaning surfaces and hard-to-reach areas

③ Remove flux residues and excess materials

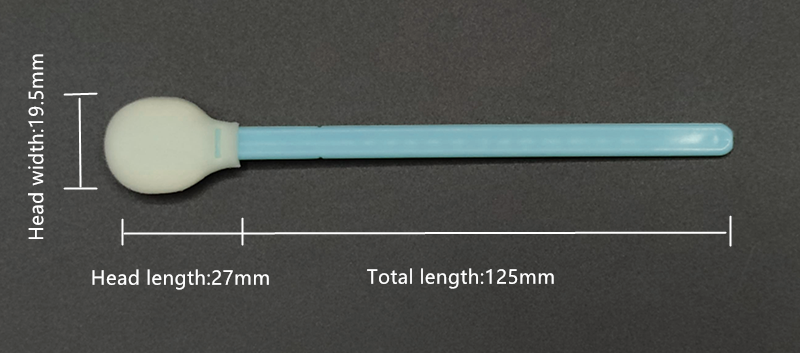

Specification of Other Hot Selling Cleanroom Swab

|

Model No.

|

Total Length

|

Tip Width

|

Tip Thickness

|

Tip Length

|

Handle Width

|

Handle Thickness

|

Handle Length

|

|

MFS-707

|

129mm

|

17mm

|

9.5mm

|

26mm

|

6.5mm

|

2.7mm

|

103mm

|

|

MFS-708

|

125mm

|

19.5mm

|

10mm

|

27mm

|

6.5mm

|

2.7mm

|

98mm

|

|

MFS-712

|

124mm

|

13mm

|

7.5mm

|

25mm

|

5.7mm

|

2.5mm

|

99mm

|

|

MFS-740

|

163mm

|

6mm

|

5.5mm

|

17mm

|

3mm

|

3mm

|

146mm

|

|

MFS-742

|

68.5mm

|

3.6mm

|

3.5mm

|

11.5mm

|

2.8mm

|

2.8mm

|

57mm

|

|

MFS-750

|

77mm

|

3.2mm

|

3.2mm

|

11mm

|

2.4mm

|

2.4mm

|

66mm

|

|

MFS-751

|

65mm

|

3.8mm

|

3.8mm

|

18mm

|

2.5mm

|

2.5mm

|

47mm

|

|

MFS-758

|

70mm

|

3.2mm

|

2.5mm

|

10.5mm

|

2.3mm

|

2.3mm

|

59.5mm

|

Miraclean Technology Co, Ltd.

Established in 2003, Miraclean Technology is a manufacturer specializing in producing Cleanroom Products & Printers Cleaning Products. In order to meet or even exceed the industry standard, the plant is completely equipped with DI water system, sterilization equipment and purification workshops. Miraclean is committed to providing More Reliable Cleaning products for the contamination control industry. We are continuously striving for advancement to meet the demands of the growing market.

Packing and Shipping

Certificate

Exhibition

Related Keywords