MFS750 Cleanroom pointed foam swab

- Min. Order:

- 500000 Piece/Pieces

- Min. Order:

- 500000 Piece/Pieces

- Transportation:

- Ocean, Air, Express, Land, others

- Port:

- Shenzhen Shekou Port, Shenzhen Yantian Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen |

|---|---|

| Productivity: | 1000000pcs/day |

| Supply Ability: | 1000000pcs/day |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | ISO9001, ISO14001 |

| HS Code: | 3005909000 |

| Transportation: | Ocean,Air,Express,Land,others |

| Port: | Shenzhen Shekou Port,Shenzhen Yantian Port |

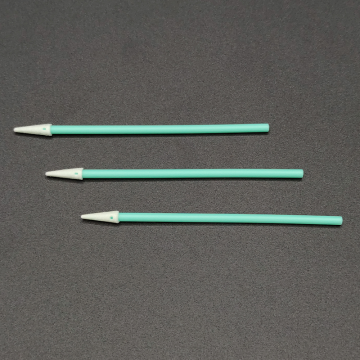

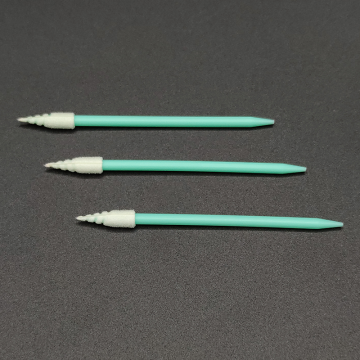

Cleanroom pointed foam swab

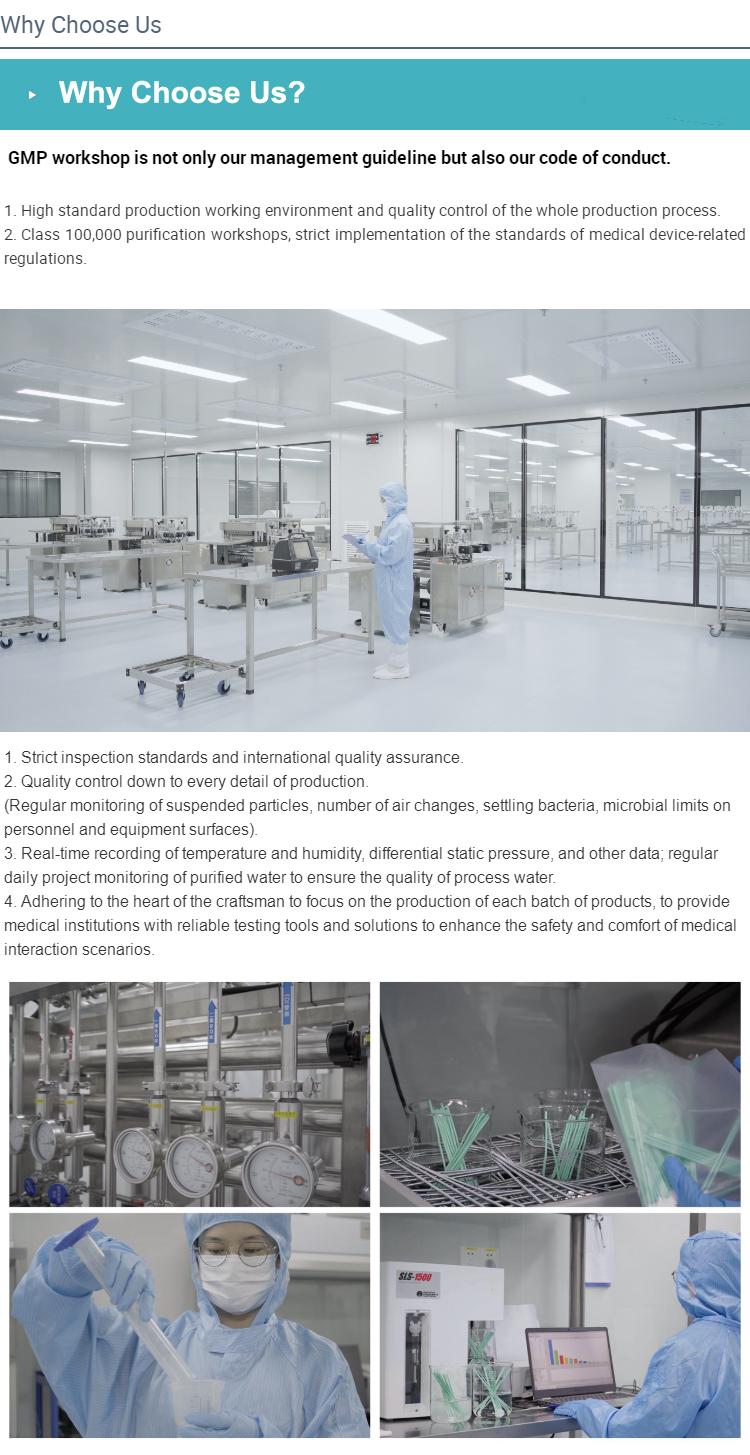

Miraclean Swabs are designed for the most demanding cleanroom precision cleaning operations. These Swabs are made of 100ppi foam to provide soft, absorbent cleaning performance. The swabs are available in a variety of head shapes and sizes enabling precision cleaning of optical, disk drive, and class III medical device components. Swab manufacturing, cleaning and packaging is performed in an ISO9001, ISO14001 cleanroom to ensure maximum cleanliness and lot to lot uniformity. Swab handle and tip materials are traceable back to raw materials.

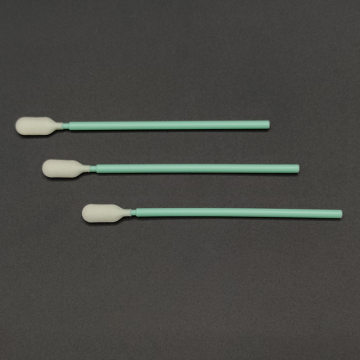

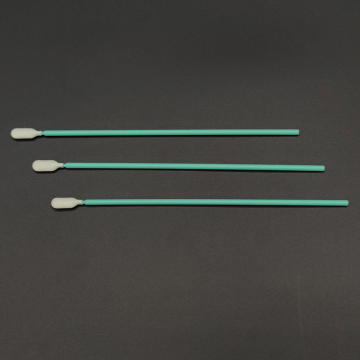

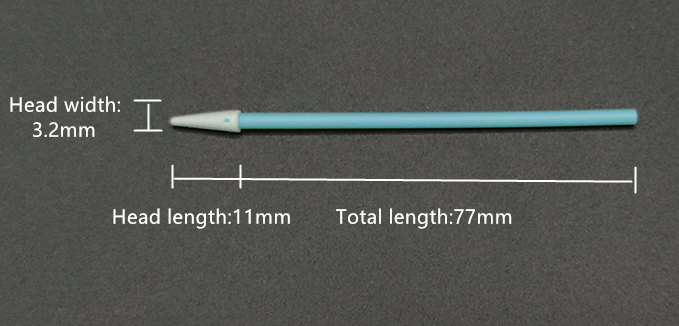

MFS-750 is thermally bonded by 100PPI open-cell polyurethane foam & light green PP handle, its large circular head possesses excellent solvent-holding capacity and durability. It is free from organic contaminants such as silicone, amide and phthalate esters, and it features very low non-volatile residue (NVR), ion content and particle generation. MFS-750 is specifically designed for general purpose cleaning of curve surfaces, and it also could be used as the disinfectant swab for medical application.

■ Free from silicone, amide and phthalate esters

■ Low in particles, ion content and non-volatile residue

■ High solvent-holding capacity, compact and non-abrasive tip

■ Compatible with most common solvents such as IPA

■ Designed with flat rectangular head & compact handle

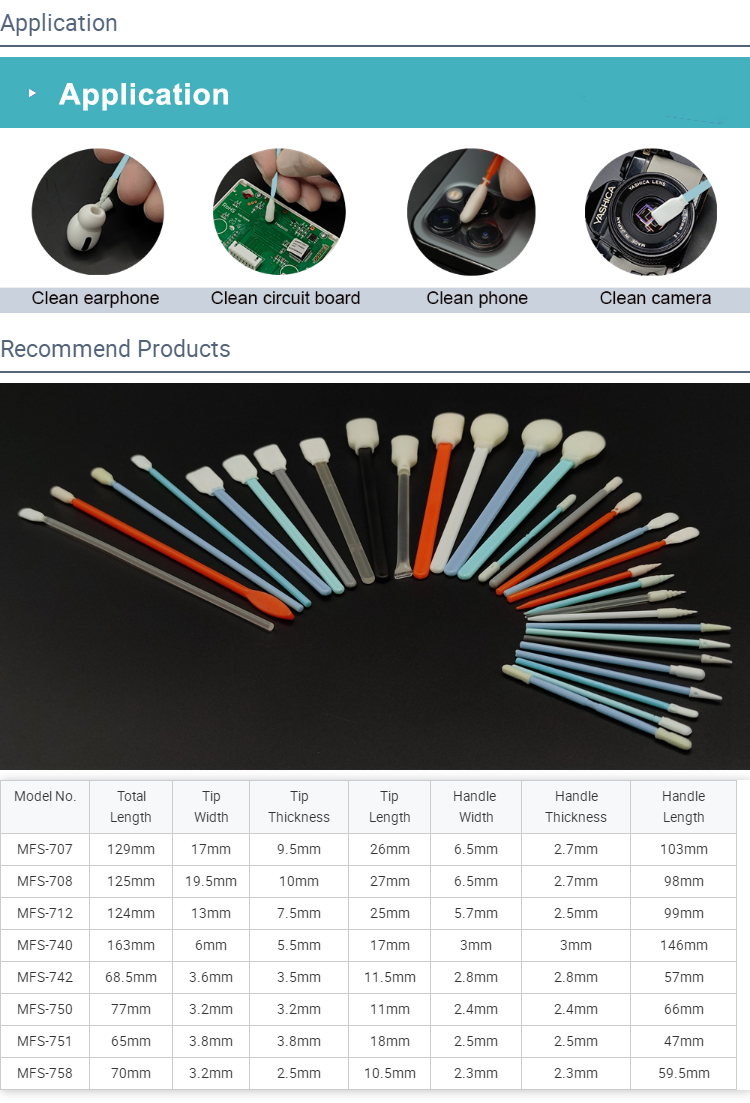

Product Applications

■ Cleaning with solvents such as IPA

■ Cleaning, surface sampling and cleaning validation

■ Remove flux residues and excess materials

Related Keywords