High precision Custom CNC machining Copper Casting Parts

-

USD1.52≥10 Piece/Pieces

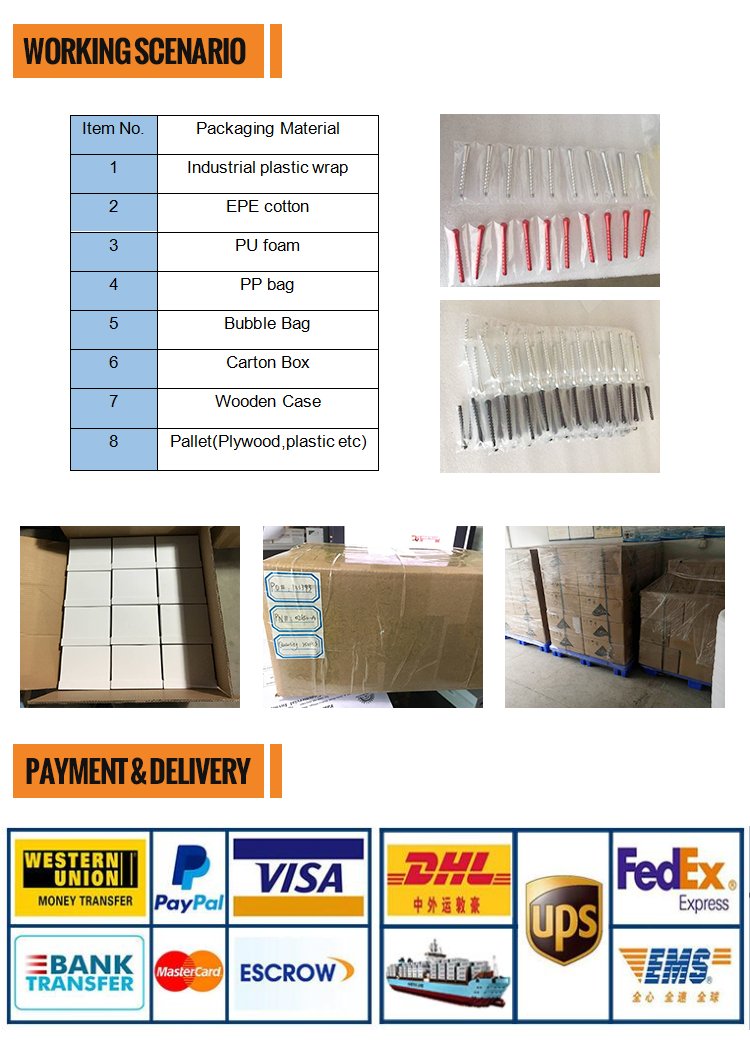

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 10000 Piece/Pieces |

| Supply Ability: | 200000 pieces per Month |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

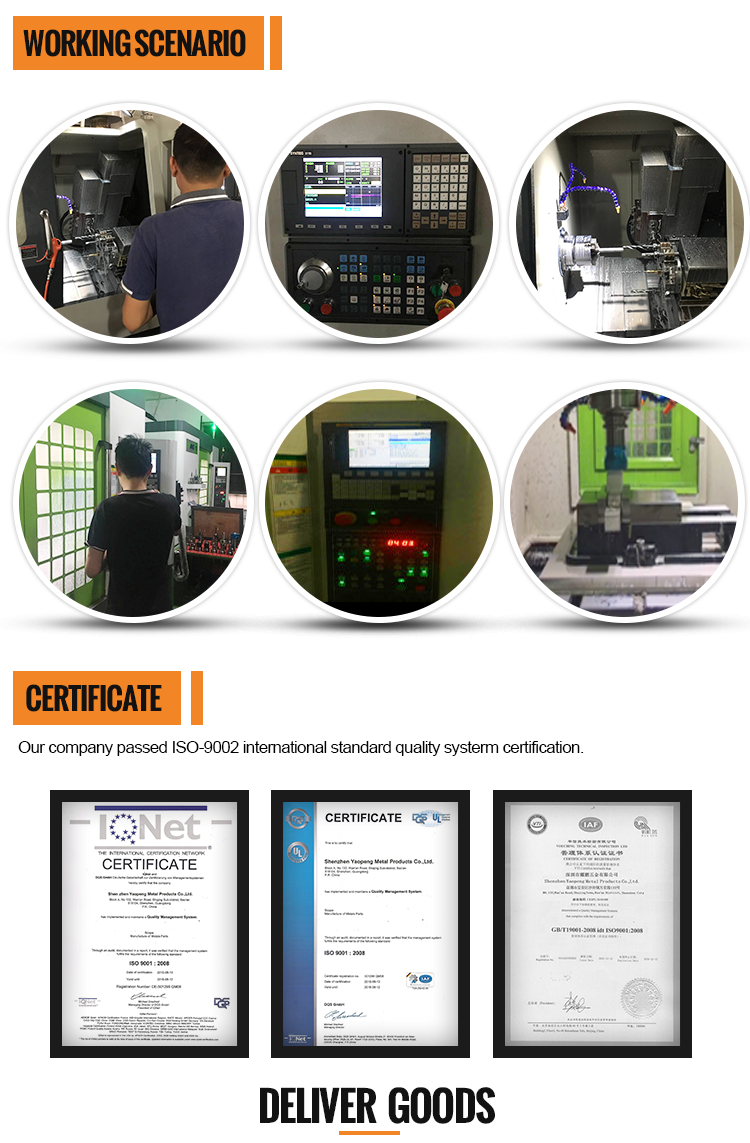

| Certificate: | ISO 9001,ISO 14001 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

High precision Custom CNC machining Copper Casting Parts

Red copper is pure copper, also known as copper, is the copper elemental, because of its color purple and named.Various properties of copper.Copper is a industry of pure copper, its melting point is 1083 ℃, no with heterogeneous change, relative density 8.9, magnesium for five times.The mass of the same volume is about 15% heavier than that of common steel.Because it has rose red, the surface formed oxidation film is purple, so commonly known as copper.It is copper with a certain amount of oxygen, so it is also called copper with oxygen.

Red copper has good electrical conductivity and thermal conductivity, plasticity is excellent, easy to hot pressure and cold pressure processing, a large number of used in the manufacture of wire, cable, brush, electric spark dedicated electrical corrosion copper products required good electrical conductivity.

If you are interested in our products, please contact me.The sincerity anticipates your reply .

We also producing Die Casting, Plastic Parts, Sheet Metal, CNC Machining Parts, CNC Turning Parts,.

|

Product Name |

High precision Custom CNC machining Copper Casting Parts |

|

Micro machining |

yes |

|

Tolerance |

0.003mm-0.01mm |

|

Surface finish |

Based on customer requirements, we can do Plating(Zinc plated, Nickel plated, Chrome plated,etc), polishing(precision can reach +/-0.005mm), knurling, anodizing, Black Oxide, heat treatment, sandblasting, powder coating, etc. |

|

Precision processing |

turning, milling, drilling, grinding, wire-EDM cutting etc |

|

Material range |

Metal: Stainless Steel, Brass,Copper, Bronze, Aluminum, Steel, Carbon Steel etc. |

|

|

Plastic : PU, PVC, POM, PMMA, Nylon ,HDPE etc. |

|

QC(inspection everywhere) |

- Technicians self-check in production |

|

|

- Engineer spot check in production. |

|

|

- QC inspect after products finished |

|

|

- International sales who were trained the technical know-how spot check before shipping to ensure the quality. |

|

High-Quality |

rich manufacturing experience,competitive price |

Related Keywords